On the surface, both PTFE and graphite packing materials are excellent, low-maintenance choices for sealing applications. They share several common characteristics, including a braided construction, a low coefficient of friction, exceptional durability, and long shelf lives, making them popular solutions for valves and rotating shafts.

While PTFE and graphite share foundational traits as effective, low-friction sealants, their core difference lies in their composition. PTFE is a synthetic polymer insulator, while graphite is a natural carbon conductor, dictating their suitability for specific chemical, thermal, and electrical environments.

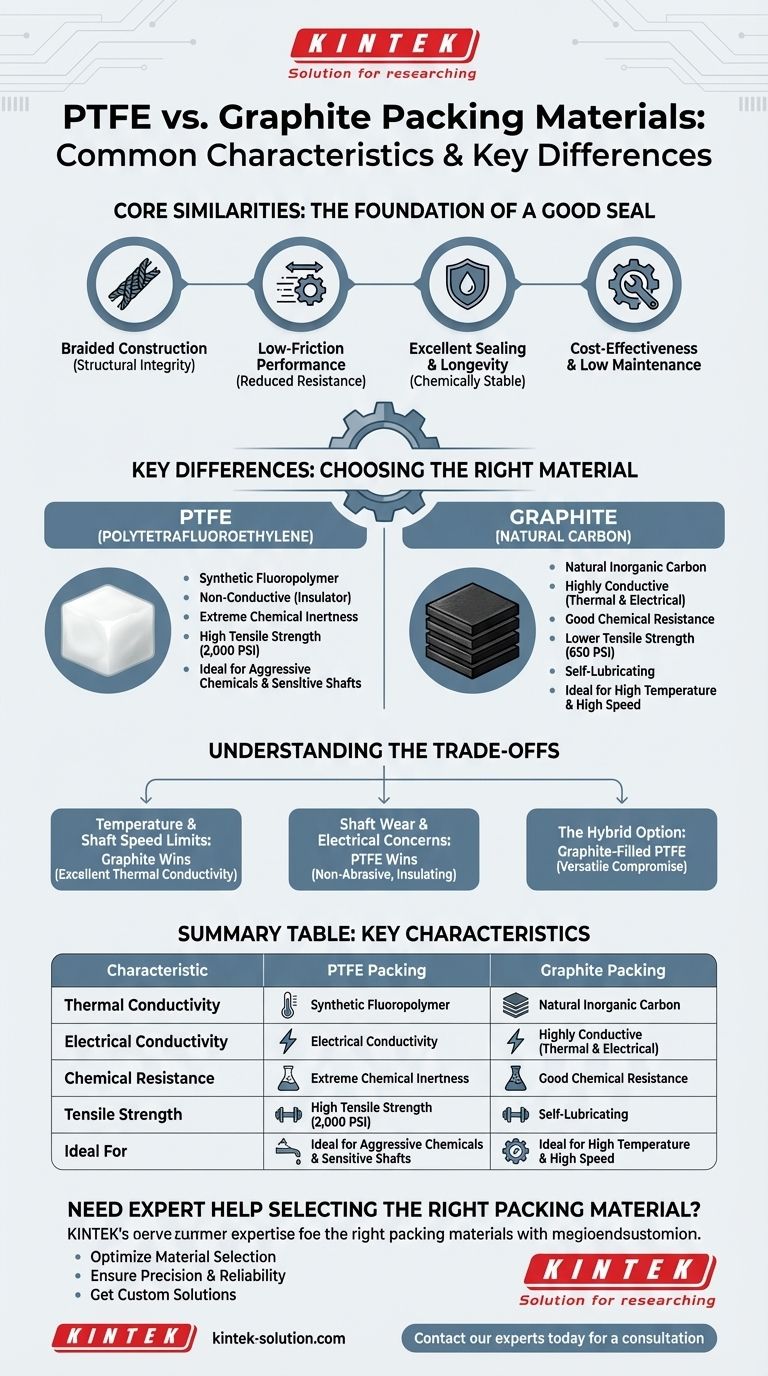

Core Similarities: The Foundation of a Good Seal

Both materials serve a similar fundamental purpose, which results in several shared design and performance attributes.

Braided Construction for Durability

Most packing made from PTFE or graphite is manufactured in a braided style. This construction method imparts significant structural integrity, allowing the packing to withstand pressure and mechanical stress without fraying or extruding.

Low-Friction Performance

A key shared trait is a low coefficient of friction. This ensures that the packing creates a reliable seal against a rotating shaft or valve stem with minimal resistance, reducing operational energy loss and preventing excess heat generation.

Excellent Sealing and Longevity

Both materials are proven to be excellent sealants that prevent leakage of fluids or gases. They are chemically stable and resistant to degradation, which gives them a very long shelf life in storage and a long service life once installed.

Cost-Effectiveness and Low Maintenance

In many standard industrial applications, both PTFE and graphite are considered cost-effective and low-maintenance solutions. Their durability and reliability reduce the frequency of equipment shutdowns for packing replacement.

Key Differences: Choosing the Right Material for the Job

Understanding the fundamental distinctions between these materials is critical for selecting the correct packing for your specific operating conditions.

Material Composition and Origin

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer, appearing as a white, waxy solid. Graphite is a naturally occurring, inorganic form of pure carbon, presenting as a black, slightly greasy material.

Thermal and Electrical Conductivity

This is a critical differentiator. Graphite is highly conductive of both heat and electricity. This allows it to dissipate heat away from the shaft, making it ideal for high-speed and high-temperature applications.

In contrast, PTFE is a non-conductive material, acting as an excellent electrical and thermal insulator.

Chemical Resistance

PTFE is renowned for its extreme chemical inertness. It is resistant to nearly all industrial chemicals, acids, and corrosive agents, with the rare exception of molten alkali metals.

While graphite is also chemically resistant, PTFE is generally considered the superior choice for the most aggressive chemical sealing applications.

Mechanical Strength and Wear

PTFE packing has a significantly higher tensile strength (2,000 PSI) compared to graphite (650 PSI), making it more resistant to stretching under load.

However, graphite is naturally self-lubricating, which provides excellent protection against wear in both wet and dry conditions. PTFE, while inherently slippery, can also be combined with lubricants or graphite fillers to enhance its wear properties.

Understanding the Trade-offs

Neither material is universally superior; the choice involves balancing their inherent advantages and disadvantages against your application's demands.

Temperature and Shaft Speed Limits

Graphite's ability to conduct and dissipate heat makes it the clear winner for extreme temperatures and high shaft speeds. PTFE's insulating properties can cause heat to build up, limiting its use in such demanding dynamic applications.

Shaft Wear and Electrical Concerns

PTFE is exceptionally smooth and non-abrasive, making it an excellent choice for protecting sensitive or polished shafts from wear.

Because graphite is electrically conductive, it can create a risk of galvanic corrosion when used with certain dissimilar metals in a corrosive electrolyte. This must be considered during material selection for the shaft and housing.

The Hybrid Option: Graphite-Filled PTFE

A common solution is graphite-filled PTFE packing. This hybrid material combines PTFE's superior chemical resistance and strength with graphite's self-lubrication and improved thermal properties, offering a versatile compromise for a wider range of applications.

Making the Right Choice for Your Application

To select the optimal material, you must first define your most critical operational requirement.

- If your primary focus is extreme chemical resistance: Pure PTFE packing is the superior and safest choice for aggressive media.

- If your primary focus is high-temperature or high-speed performance: Graphite's thermal conductivity makes it the definitive solution.

- If your primary focus is protecting a sensitive shaft in a non-conductive environment: PTFE's smooth, non-abrasive nature is ideal.

- If your primary focus is a balanced performance for general chemical service: Graphite-filled PTFE offers a versatile and robust compromise.

Choosing the right packing material is a matter of aligning the unique properties of the material with the precise demands of your system.

Summary Table:

| Characteristic | PTFE Packing | Graphite Packing |

|---|---|---|

| Thermal Conductivity | Insulator (Poor) | Conductor (Excellent) |

| Electrical Conductivity | Insulator | Conductor |

| Chemical Resistance | Excellent (Inert) | Good |

| Tensile Strength | High (2,000 PSI) | Lower (650 PSI) |

| Ideal For | Aggressive Chemicals, Sensitive Shafts | High Temperature, High Speed |

Need Expert Help Selecting the Right Packing Material?

Choosing between PTFE and graphite is critical for your application's performance and safety. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom seals and packing materials for the most demanding environments in the semiconductor, medical, and industrial sectors.

We can help you:

- Optimize Material Selection: Leverage our expertise to choose the perfect material—be it pure PTFE, graphite, or a hybrid—for your specific temperature, chemical, and operational requirements.

- Ensure Precision and Reliability: Our components are manufactured to the highest tolerances, ensuring a perfect seal and long service life.

- Get Custom Solutions: From prototypes to high-volume orders, we provide custom fabrication to meet your exact specifications.

Don't leave your sealing performance to chance. Contact our experts today for a consultation and let us provide a solution engineered for your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the function of a teflon check valve in control systems? Prevent Backflow in Corrosive & High-Temp Processes

- How are PTFE coated fasteners beneficial in the automotive sector? Enhance Reliability and Simplify Maintenance

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What temperature ranges can FEP and PTFE encapsulated O-rings withstand? A Guide to Extreme Environment Sealing

- How do lined valves compare to plastic pipes in terms of pressure and temperature resistance? Unlock Superior Performance

- Why are PTFE spring-energized seals ideal for semiconductor manufacturing? Ensure Purity and Maximize Yield

- What is PTFE Spiral Wrap and what are its uses? Protect Cables in Extreme Environments

- What are the key considerations when machining PTFE? Master the Art of Precision Machining