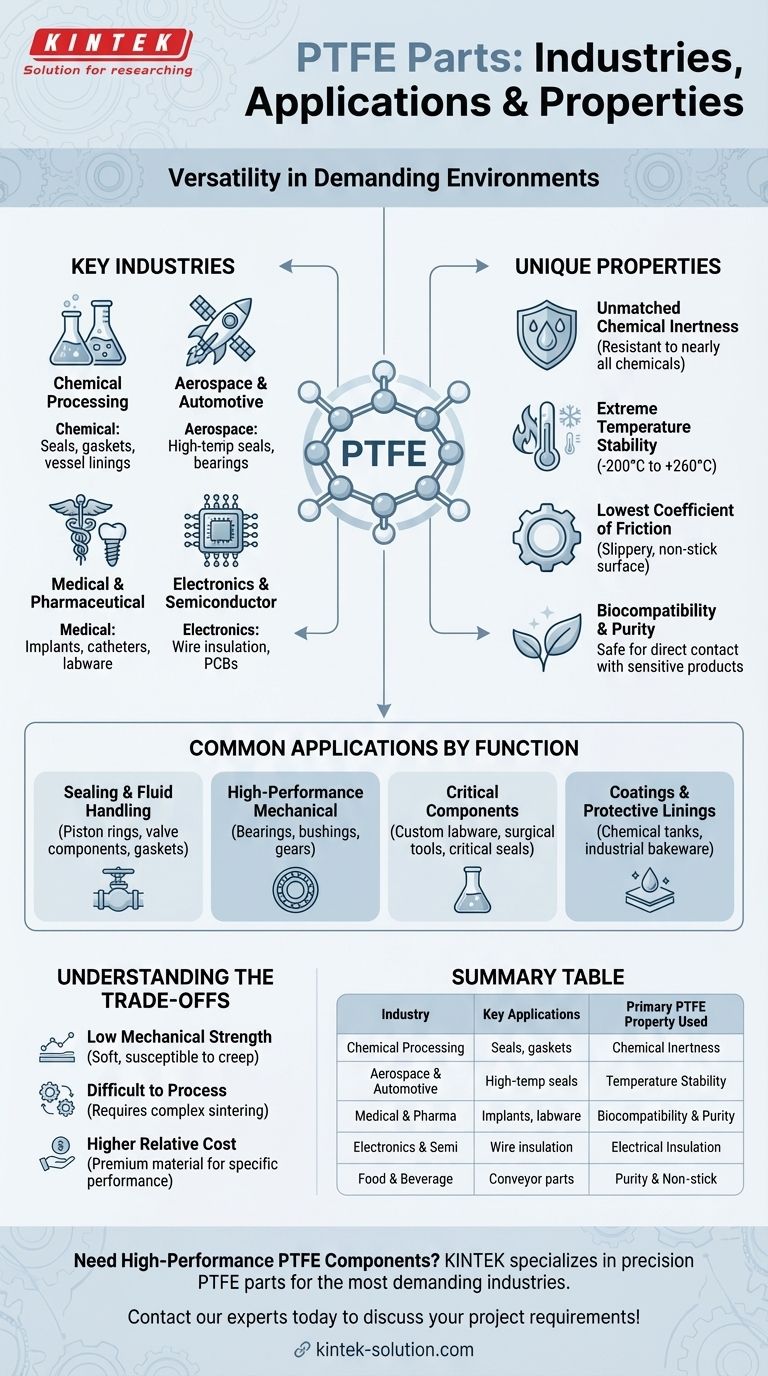

In short, Polytetrafluoroethylene (PTFE) parts are used across nearly every demanding industry imaginable. Its unique properties make it indispensable in sectors like chemical processing, aerospace, medical and pharmaceuticals, electronics, and food production for applications ranging from high-performance seals and bearings to non-stick coatings and biocompatible implants.

The versatility of PTFE doesn't come from a single feature, but from its rare combination of near-total chemical inertness, extreme temperature stability, and an incredibly low coefficient of friction. This makes it a premier problem-solving material for environments where other materials would quickly fail.

Why PTFE is a Go-To Material in Critical Industries

The widespread adoption of PTFE is a direct result of its fundamental material properties. Understanding these characteristics explains its presence in everything from spacecraft to cooking pans.

Unmatched Chemical Inertness

PTFE is resistant to nearly all chemicals, solvents, and corrosive agents. This makes it the default choice for handling aggressive substances.

This property is critical in the chemical processing, oil and gas, and pharmaceutical industries for components like valve seats, seals, gaskets, and vessel linings.

Extreme Temperature Stability

PTFE maintains its integrity across a vast temperature range, from cryogenic lows to highs of 260°C (500°F).

This resilience is essential for applications in aerospace, automotive, and power generation, where components are exposed to extreme heat and pressure fluctuations.

The Lowest Coefficient of Friction

Known for its slippery, non-stick surface, PTFE has one of the lowest coefficients of friction of any solid material.

This makes it ideal for mechanical applications requiring smooth movement with minimal wear, such as bearings, bushings, gears, and slide plates.

Purity and Biocompatibility

PTFE is physiologically inert and can be produced to high purity standards, making it safe for direct contact with sensitive products.

This is non-negotiable in the medical, pharmaceutical, and food and beverage industries for items like implants, catheters, laboratory containers, and conveyor components.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength, meaning it can withstand high voltages without breaking down.

This property is leveraged in the electronics and semiconductor industries for wire insulation, printed circuit boards (PCBs), and custom processing tools.

A Snapshot of Common PTFE Applications by Function

While industries vary, the functional roles that PTFE parts play are often consistent, leveraging one or more of its core properties.

Sealing and Fluid Handling

This is one of the most common uses for PTFE. Its ability to create a durable, chemically resistant seal is invaluable.

Examples include piston rings, valve components (balls, seats, bodies), pump parts, gaskets, and expansion joints in chemical plants.

High-Performance Mechanical Components

Where low friction and durability are paramount, PTFE excels.

It is frequently machined into bearings, bushings, and gears for compressors, textile machinery, and other industrial equipment.

Critical Components in Specialized Fields

In high-tech and regulated sectors, precision and reliability are key.

PTFE is used for custom labware in semiconductor processing, implants and surgical tools in medicine, and critical seals and valves in aerospace.

Coatings and Protective Linings

The famous non-stick property of PTFE is used well beyond consumer cookware.

It serves as a lining for chemical tanks, a coating for industrial bakeware, and even as a stain-resistant treatment for fabrics and carpets.

Understanding the Trade-offs

No material is perfect. While PTFE offers exceptional performance, its limitations are important to recognize for proper application.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for high-load structural applications and can be susceptible to "creep" or deforming under sustained pressure.

Difficult to Process

Unlike many thermoplastics, PTFE cannot be easily melt-processed or injection molded. It requires a more complex and often more costly sintering process, similar to powdered metallurgy.

Higher Relative Cost

Compared to commodity plastics like nylon or polyethylene, PTFE is a premium material with a higher cost. Its use is typically justified by performance requirements that other materials cannot meet.

Making the Right Choice for Your Application

Selecting PTFE is a decision driven by the specific demands of the operating environment.

- If your primary focus is chemical resistance and purity: PTFE is the industry standard for seals, linings, and fluid-handling components in chemical, pharmaceutical, and food processing.

- If your primary focus is low friction and self-lubrication: It is an excellent choice for bearings, bushings, and other mechanical parts where reducing wear is critical.

- If your primary focus is high-temperature performance: PTFE gaskets and seals provide reliable service in demanding aerospace, automotive, and industrial applications.

- If your primary focus is electrical insulation: It is a top-tier material for high-frequency electronics and critical insulating components.

Ultimately, PTFE is the material of choice when performance and reliability in extreme conditions are non-negotiable.

Summary Table:

| Industry | Key Applications | Primary PTFE Property Used |

|---|---|---|

| Chemical Processing | Seals, gaskets, vessel linings | Chemical Inertness |

| Aerospace & Automotive | High-temperature seals, bearings | Temperature Stability |

| Medical & Pharmaceutical | Implants, catheters, labware | Biocompatibility & Purity |

| Electronics & Semiconductor | Wire insulation, PCBs | Electrical Insulation |

| Food & Beverage | Conveyor components, seals | Purity & Non-stick Surface |

Need High-Performance PTFE Components?

At KINTEK, we specialize in manufacturing precision PTFE parts—including seals, liners, and custom labware—for the most demanding industries. Whether you're in semiconductor manufacturing, medical technology, or industrial processing, our custom fabrication services ensure you get components that meet your exact specifications, from prototypes to high-volume orders.

Let us help you solve your toughest material challenges. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support