In short, PTFE lined butterfly valves enhance safety by creating a chemically inert barrier between corrosive industrial media and the valve's structural metal components. This design provides exceptional sealing to prevent hazardous leaks, while the non-stick surface prevents material buildup that could lead to contamination or dangerous clogs.

The fundamental safety risk in fluid control is containment failure. PTFE lined butterfly valves directly address this by using the liner to shield the valve's core structure from chemical attack, ensuring long-term mechanical integrity and preventing the escape of hazardous materials.

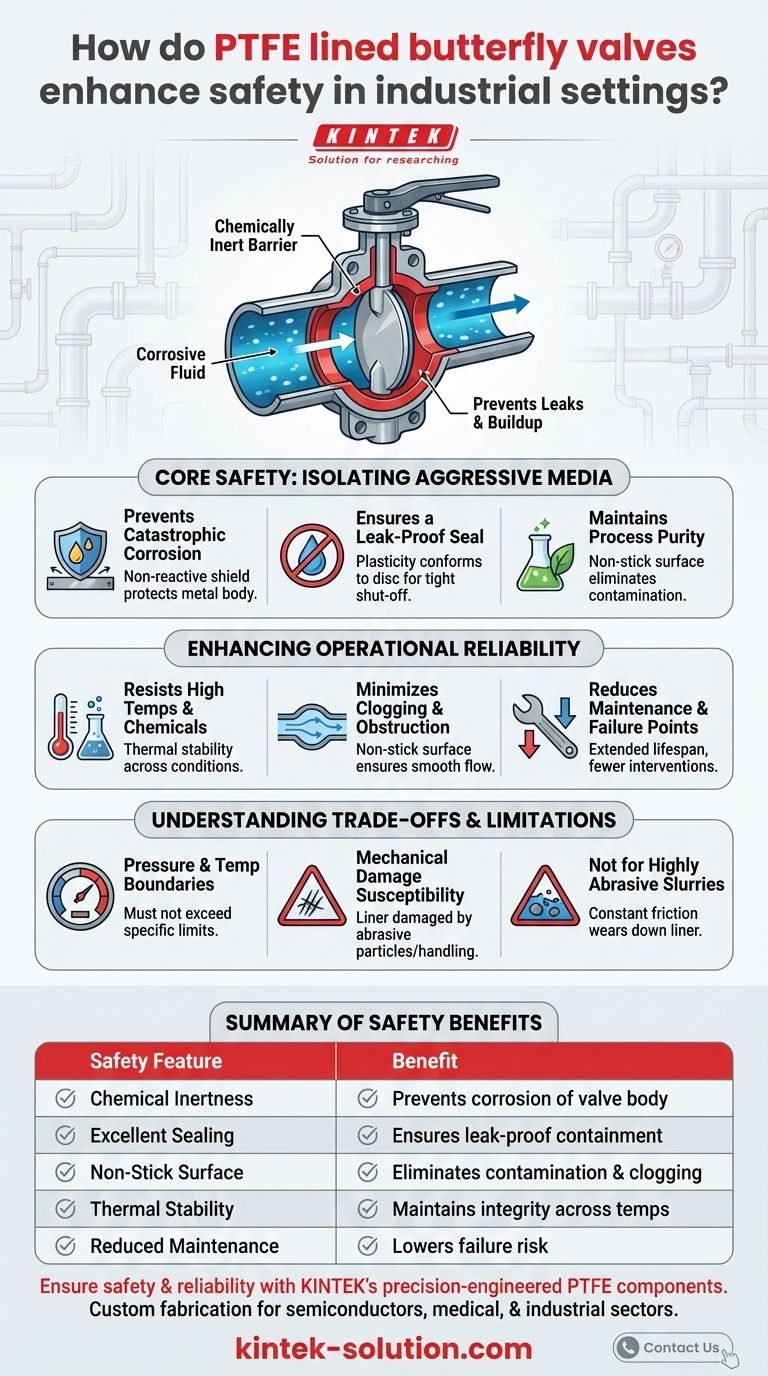

The Core Safety Principle: Isolating the Aggressive Media

The primary function of the PTFE liner is to completely isolate the substance flowing through the pipe from the metal body of the valve. This single design choice creates several layers of safety.

Preventing Catastrophic Corrosion

The most significant safety benefit is the prevention of corrosion. Aggressive acids, bases, and solvents can quickly degrade standard metal valves, leading to structural failure and dangerous leaks.

A PTFE (polytetrafluoroethylene) liner acts as a robust, non-reactive shield. It ensures the valve's metal body, which provides the pressure-containing strength, is never exposed to the corrosive media.

Ensuring a Leak-Proof Seal

PTFE's material properties create a highly effective and durable seal. The inherent plasticity of the liner allows it to conform perfectly to the valve disc, creating a tight shut-off that prevents the escape of hazardous gases or liquids.

This robust seal is maintained over many cycles, reducing the risk of fugitive emissions and ensuring the system can be reliably isolated for maintenance or in an emergency.

Maintaining Process Purity

In industries like pharmaceuticals or food and beverage, safety is synonymous with purity. The non-stick, inert nature of PTFE is critical here.

The liner prevents media from sticking to the valve's internal surfaces, which eliminates material accumulation. This not only prevents cross-contamination between batches but also stops the buildup of material that could harden, obstruct the valve, or foster bacterial growth.

Enhancing Operational Reliability

A safe valve is a reliable one. The properties of the PTFE lining contribute directly to the valve's long-term performance and predictability, reducing the chance of unexpected failures.

Resisting High Temperatures and Chemicals

PTFE has excellent thermal stability and is resistant to nearly all industrial chemicals. This means the valve maintains its structural integrity and sealing capability across a wide range of operating conditions without degrading.

This resilience makes the valve's performance predictable and reliable, a cornerstone of any safe industrial process.

Minimizing Clogging and Flow Obstruction

The famous non-stick quality of PTFE ensures a smooth flow path. Media, especially slurries or viscous fluids, are less likely to build up and cause a clog.

A clogged valve can lead to dangerous over-pressurization of a system or prevent the valve from closing fully in an emergency. The self-cleaning nature of the PTFE surface mitigates this risk.

Reducing Maintenance and Failure Points

Because the liner protects the valve's core components from wear and corrosion, PTFE lined valves have a significantly extended lifespan and require less frequent maintenance.

Every maintenance intervention introduces a potential point of failure or human error. By reducing the need for repair or replacement, these valves contribute to a safer, more stable operating environment.

Understanding the Trade-offs

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations is key to using them safely.

Pressure and Temperature Boundaries

Every PTFE formulation has specific pressure and temperature limits. Exceeding these can cause the liner to deform or fail, compromising the protective barrier. It is crucial to select a valve rated for the specific operating conditions of your system.

Susceptibility to Mechanical Damage

The PTFE liner can be damaged by abrasive particles in the media (like in a mining slurry) or by improper handling during installation. A scratch or gouge in the liner creates a direct path for corrosive media to attack the metal body, negating the valve's primary safety feature.

Not Ideal for Abrasive Slurries

While excellent for corrosive liquids and gases, PTFE lined valves are generally not recommended for highly abrasive media. The constant friction from sharp or hard particles can eventually wear down the liner, leading to failure.

Making the Right Choice for Your Application

Selecting the correct valve is a critical safety decision. The suitability of a PTFE lined butterfly valve depends entirely on your primary operational goal.

- If your primary focus is handling highly corrosive chemicals: The PTFE liner is essential for preventing valve body degradation and ensuring long-term containment.

- If your primary focus is maintaining high-purity processes: The inert, non-stick surface is your best defense against contamination and material buildup.

- If your primary focus is maximizing long-term reliability: The combination of chemical resistance, thermal stability, and reduced maintenance makes these valves a superior choice for minimizing lifecycle risks.

By isolating the process from the valve's structure, PTFE lining provides a robust and reliable solution for safely controlling challenging fluids.

Summary Table:

| Safety Feature | Benefit |

|---|---|

| Chemical Inertness | Prevents corrosion of valve body by aggressive media |

| Excellent Sealing | Ensures leak-proof containment of hazardous materials |

| Non-Stick Surface | Eliminates contamination and prevents clogging |

| Thermal Stability | Maintains integrity across a wide temperature range |

| Reduced Maintenance | Lowers risk of failure from frequent interventions |

Ensure the safety and reliability of your fluid handling systems with KINTEK's precision-engineered PTFE components.

Our PTFE lined butterfly valves are designed to provide the ultimate protection against corrosion and leaks in demanding applications. Whether you're in the semiconductor, medical, laboratory, or industrial sector, KINTEK delivers custom fabrication from prototypes to high-volume orders, ensuring your components meet the highest standards of performance and safety.

Contact us today to discuss your specific requirements and let our experts help you enhance the safety and efficiency of your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key properties of Teflon bearings? Engineered for Extreme Environments

- How are Teflon bearings manufactured? A Guide to Machining, Molding, and Coating

- What are the key technical features of Teflon backup rings? Essential Support for High-Pressure Seals

- What are the benefits of PTFE spring-energized seals? Superior Chemical & Thermal Resilience for Harsh Environments

- What are some common alternatives to Teflon sheets for heat press applications? Find the Right Protective Sheet

- What are the advantages of machining Teflon? Unlock Superior Precision and Complex Designs

- How does PTFE's non-stick property benefit industrial applications? Boost Efficiency & Reduce Downtime

- How does the quality of Teflon bearings compare to traditional bearings? Superior Performance in Harsh Environments