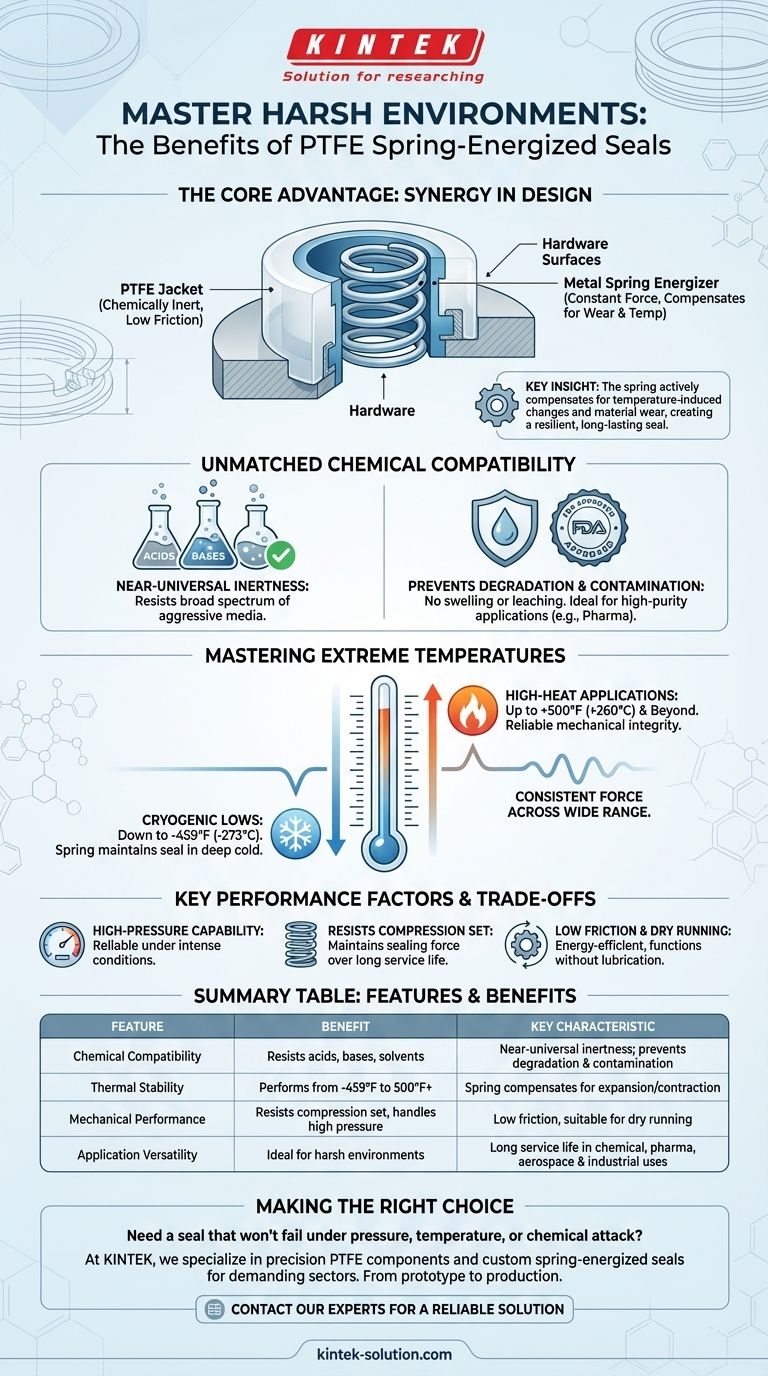

At their core, PTFE spring-energized seals provide exceptional chemical compatibility and thermal stability due to their unique two-part construction. The Polytetrafluoroethylene (PTFE) jacket is nearly universally inert, resisting degradation from aggressive chemicals like acids and solvents, while the internal spring ensures the seal maintains a constant force against hardware across an extremely wide temperature range, from cryogenic lows below -250°F to high-heat applications above 500°F.

The fundamental advantage is not just the material properties of PTFE, but how the internal spring actively compensates for temperature-induced dimensional changes and material wear. This creates a resilient, long-lasting seal in environments where traditional elastomeric seals would quickly degrade and fail.

How the Design Achieves Unmatched Resilience

The performance of these seals is a direct result of the synergy between their two primary components: the polymer jacket and the metal spring energizer.

The Role of the PTFE Jacket

PTFE is a high-performance fluoropolymer renowned for its chemical inertness. This property means it does not react with the vast majority of industrial fluids.

This material provides an extremely low coefficient of friction, allowing it to operate in dynamic applications with minimal wear and heat generation, even without lubrication.

The Function of the Internal Spring

The spring provides the initial seating force when the seal is installed. More importantly, it delivers a constant, live force throughout the seal's life.

This stored energy ensures the seal lips remain in contact with the mating surfaces, compensating for wear, pressure fluctuations, and the expansion or contraction of the seal jacket due to extreme temperature changes.

Unpacking Chemical Compatibility

The primary reason to specify a PTFE seal is often its ability to survive exposure to aggressive media that would destroy other materials.

Near-Universal Inertness

The PTFE jacket is resistant to a broad spectrum of chemicals, including potent acids, bases, solvents, and corrosive fluids.

This makes them a default choice for demanding industries like chemical processing and pharmaceutical manufacturing, where seal integrity is directly tied to safety and product purity.

Preventing Degradation and Contamination

Unlike rubber-based seals, PTFE does not swell, harden, or degrade when exposed to harsh chemicals.

This stability is critical in high-purity applications. Because the material is inert, it will not leach contaminants into the process media, a key reason many grades are FDA-approved.

Mastering Extreme Temperatures

Many sealing materials lose their mechanical properties at temperature extremes, becoming either brittle or overly soft. PTFE spring-energized seals are engineered to overcome this.

Performance in High-Heat Environments

These seals reliably function in continuous service at temperatures exceeding 500°F (260°C).

At these elevated temperatures, the seal maintains its mechanical integrity and the spring continues to provide consistent force, preventing leaks that would occur as hardware expands.

Reliability in Cryogenic Conditions

On the other end of the spectrum, PTFE seals perform exceptionally well in cryogenic conditions, with some configurations rated for temperatures as low as -459°F.

While other materials become brittle and crack in deep cold, the spring energizer ensures the stiffened PTFE jacket maintains a tight seal against the contracting hardware.

Understanding the Trade-offs and Key Factors

While chemical and thermal resistance are the headline benefits, other performance characteristics are equally critical in specifying these seals.

High-Pressure Capability

The spring's constant radial force allows these seals to perform reliably under high-pressure conditions where other seals might be extruded or dislodged.

Resisting Compression Set

Elastomeric seals can permanently deform under prolonged compression, a phenomenon known as compression set. PTFE seals are highly resistant to this, ensuring they continue to provide a sealing force over very long service periods.

Low Friction and Dry Running

The low-friction nature of PTFE is a significant advantage, reducing energy consumption in rotating equipment and allowing the seal to function effectively even in dry or poorly lubricated conditions.

The Importance of Configuration

The primary "trade-off" is not in performance but in complexity. The specific grade of PTFE, the spring material (e.g., stainless steel, Elgiloy), and the spring geometry must be carefully matched to the application's pressure, temperature, and media to achieve optimal results.

Making the Right Choice for Your Goal

Specifying a PTFE spring-energized seal is a decision for applications where reliability in harsh conditions is paramount.

- If your primary focus is aggressive chemical processing: These seals provide unmatched resistance to degradation, ensuring long service life and process purity.

- If your primary focus is aerospace or cryogenic applications: Their stability across extreme temperature ranges, from high heat to deep cold, prevents leaks where other materials would fail.

- If your primary focus is high-purity manufacturing (e.g., pharmaceutical): The inertness of PTFE prevents contamination, and many grades are FDA-approved for these sterile environments.

- If your primary focus is long-life or high-pressure systems: The spring's constant force resists compression set and ensures a reliable seal under demanding physical conditions.

Ultimately, selecting a PTFE spring-energized seal is a strategic engineering decision for applications where failure is not an option.

Summary Table:

| Feature | Benefit | Key Characteristic |

|---|---|---|

| Chemical Compatibility | Resists acids, bases, solvents | Near-universal inertness; prevents degradation & contamination |

| Thermal Stability | Performs from -459°F to 500°F+ | Spring compensates for expansion/contraction |

| Mechanical Performance | Resists compression set, handles high pressure | Low friction, suitable for dry running |

| Application Versatility | Ideal for harsh environments | Long service life in chemical, pharmaceutical, aerospace & industrial uses |

Need a seal that won't fail under pressure, temperature, or chemical attack?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom spring-energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals are perfectly configured for your specific media, temperature, and pressure requirements—from prototype to high-volume production.

Contact our experts today to discuss your application and receive a solution built for reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers