When precision is non-negotiable for Teflon components, machining is the superior manufacturing method. Compared to processes like molding or extrusion, CNC machining delivers significantly tighter tolerances, allows for far more complex geometries, and produces a superior surface finish. This makes it the ideal choice for creating custom, high-accuracy parts, particularly in low-volume production runs where the cost of a mold would be prohibitive.

The core advantage of machining Teflon isn't just about precision; it's that this method circumvents the material's unique thermal properties. Teflon (PTFE) tends to decompose before it can properly melt, making common high-volume processes like injection molding technically challenging and often impractical.

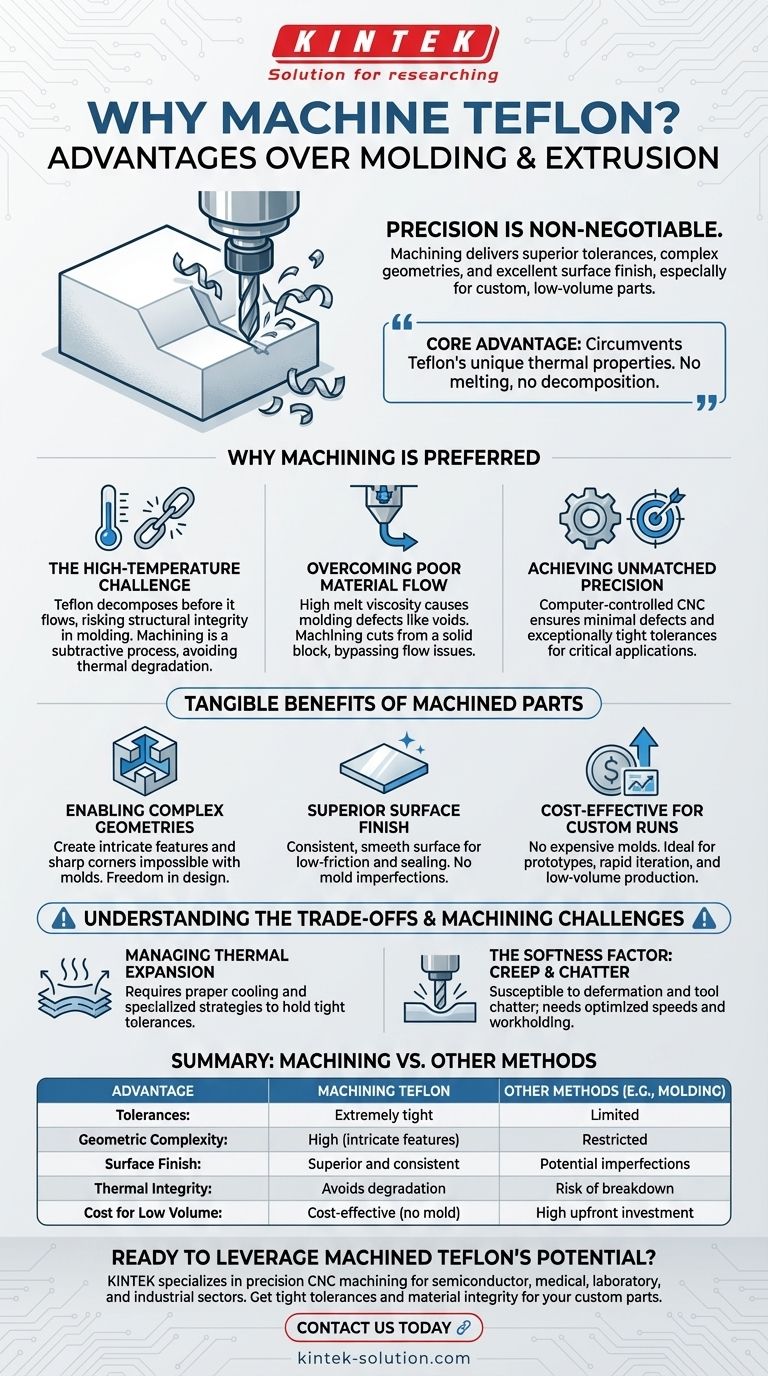

Why Machining is the Preferred Method for PTFE

The choice to machine Teflon often comes down to the fundamental nature of the material itself. Its behavior at high temperatures creates significant obstacles for any process that relies on melting and flowing.

The High-Temperature Challenge

Teflon has an extremely high melting point and a tendency to decompose or degrade before it achieves the low viscosity needed for processes like injection molding or 3D printing.

This thermal instability means that attempting to melt and inject it into a mold can compromise the material's structural integrity, leading to a weak and unreliable final part.

Machining, as a subtractive process, works the material in its solid state, completely avoiding the risks of thermal degradation.

Overcoming Poor Material Flow

Even when heated, PTFE exhibits very high melt viscosity, meaning it does not flow easily. This makes it incredibly difficult to fill the intricate details of a mold completely and consistently.

The result of poor flow is a high likelihood of defects such as voids, weak points, and incomplete features in a molded part. Machining bypasses this issue entirely by cutting the final shape from a solid block.

Achieving Unmatched Precision

CNC machining offers a level of accuracy and repeatability that is difficult to achieve with molding. Because it is a computer-controlled process, it can produce parts with minimal defects and exceptionally tight tolerances.

This precision is critical for applications like seals, insulators, and medical components where exact dimensions are essential for performance.

The Tangible Benefits of a Machined Part

Choosing to machine Teflon translates directly into higher-quality components that are better suited for demanding applications.

Enabling Complex Geometries

CNC machining can create intricate features, sharp internal corners, and complex contours that are impossible to produce with a mold. This design freedom allows engineers to create optimal parts without being constrained by the limitations of a molding process.

Superior Surface Finish

The cutting action of a CNC machine produces a smooth, consistent surface finish. Molded or extruded parts, by contrast, can have surface imperfections left by the mold itself or the extrusion die. A smooth surface is critical for low-friction and sealing applications.

Cost-Effectiveness for Custom Runs

Creating a high-quality mold for injection molding is a significant upfront investment. Machining requires no custom tooling, making it far more cost-effective for prototypes, custom parts, and low-volume production.

This allows for rapid iteration during design and affordable production of specialized components.

Understanding the Trade-offs and Machining Challenges

While machining is the superior method, it is not without its own set of technical challenges that require expertise to overcome.

Managing Thermal Expansion

Teflon has a very high coefficient of thermal expansion. Heat generated during the cutting process can cause the material to expand, making it difficult to hold tight tolerances. Managing this requires proper cooling systems and specialized machining strategies.

The Softness Factor: Creep and Chatter

PTFE is a relatively soft material. This softness can lead to tool chatter (vibrations) if cutting speeds and feeds are not optimized, resulting in a poor surface finish.

The material is also susceptible to stress creep, meaning it can deform under pressure. This requires careful workholding techniques to avoid distorting the part during the machining process.

Making the Right Choice for Your Application

Selecting the correct manufacturing process is critical to leveraging Teflon's unique properties effectively.

- If your primary focus is high-precision components or prototypes: Machining is the definitive choice for achieving tight tolerances and complex designs without the high upfront cost of a mold.

- If your primary focus is material integrity: Machining avoids the risk of thermal degradation, ensuring the final part retains all of Teflon's superior chemical, thermal, and electrical properties.

- If your primary focus is design freedom: The subtractive nature of machining allows for the creation of intricate parts that simply cannot be molded or extruded.

Ultimately, choosing to machine Teflon is choosing to prioritize precision and unlock the full performance potential of this remarkable material.

Summary Table:

| Advantage | Machining Teflon | Other Methods (e.g., Molding) |

|---|---|---|

| Tolerances | Extremely tight | Limited by mold and flow |

| Geometric Complexity | High (sharp corners, intricate features) | Restricted by mold design |

| Surface Finish | Superior and consistent | Potential for imperfections |

| Thermal Integrity | Avoids degradation (no melting) | Risk of material breakdown |

| Cost for Low Volume | Cost-effective (no mold) | High upfront mold investment |

Ready to leverage the full potential of machined Teflon for your project?

At KINTEK, we specialize in precision CNC machining of PTFE (Teflon) components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your custom parts—from prototypes to high-volume orders—achieve the tight tolerances, complex geometries, and material integrity your application demands.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability