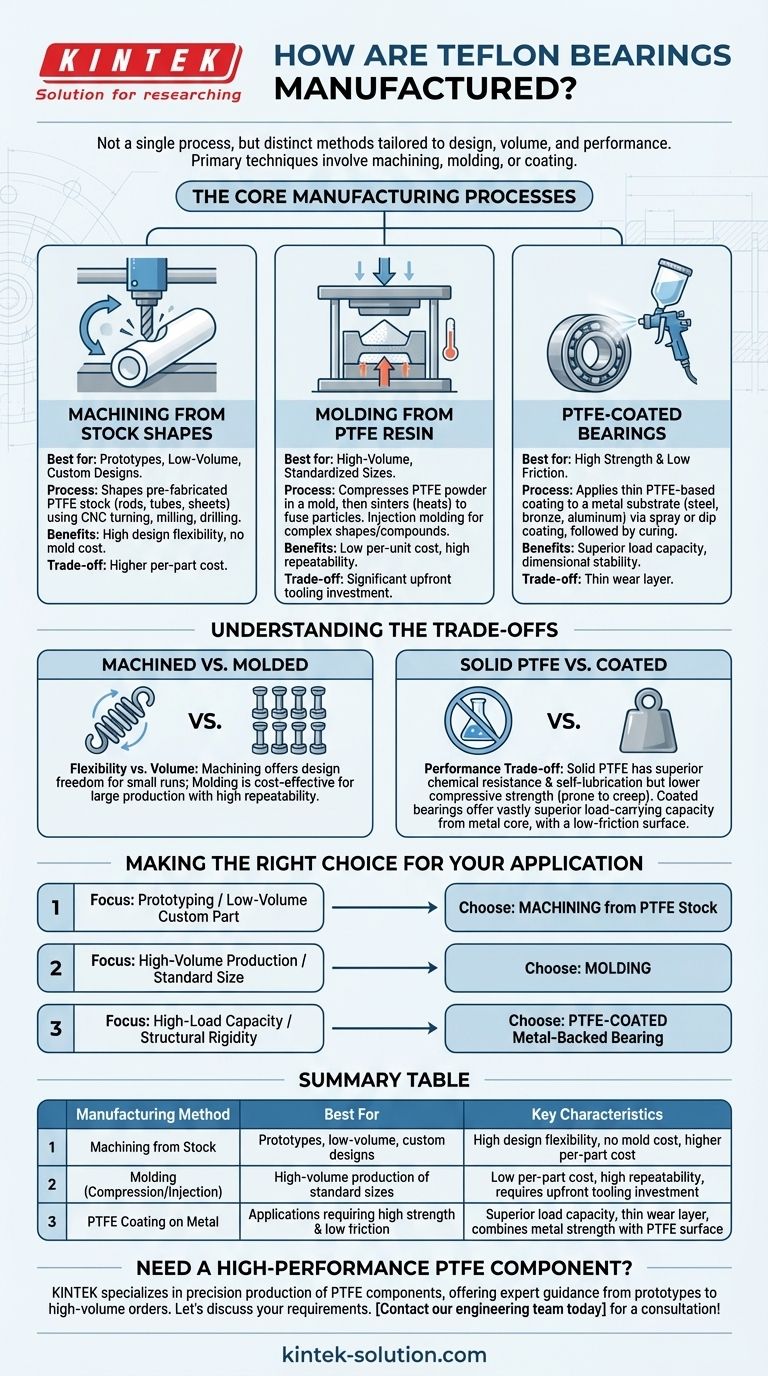

The manufacturing of Teflon (PTFE) bearings is not a single process, but rather a set of distinct methods tailored to the specific design, volume, and performance requirements of the final product. The primary techniques involve machining from solid stock shapes, molding PTFE resins into final form, or applying a PTFE coating to a more robust metal substrate.

The choice of manufacturing method is a critical engineering decision. It directly dictates the bearing's cost, geometric complexity, production volume, and fundamental performance characteristics, such as its ability to handle high loads.

The Core Manufacturing Processes

The method used to create a Teflon bearing is chosen based on the part's complexity, the required quantity, and whether the part needs to be solid PTFE or simply have a low-friction surface.

Machining from Stock Shapes

Machining is the most common method for low-volume production, prototypes, or highly precise custom designs.

The process begins with pre-fabricated PTFE stock, typically extruded rods, tubes, or sheets. This stock material is then shaped using standard CNC (Computer Numerical Control) machining techniques like turning, milling, and drilling to achieve the final bearing dimensions.

This approach offers maximum design flexibility and avoids the high upfront cost of creating a mold.

Molding from PTFE Resin

Molding is used for higher volume production of standardized or moderately complex bearing shapes, significantly reducing the per-unit cost.

Compression molding is a common technique where powdered PTFE resin is placed into a mold cavity, compressed under high pressure, and then heated in a process called sintering to fuse the particles together into a solid, durable part.

Injection molding can also be used, particularly for more complex geometries and PTFE compounds that have been blended with fillers (like glass or bronze) to improve mechanical properties.

An Alternative: PTFE-Coated Bearings

For applications requiring the high strength of metal but the low-friction surface of Teflon, coated bearings are the ideal solution. These are not solid PTFE parts.

Instead, a metal bearing substrate (often steel, bronze, or aluminum) is fabricated first. A thin layer of a PTFE-based coating is then applied to the critical contact surfaces.

This is typically done through spray coating or dip coating, followed by a curing process that bonds the low-friction layer to the metal base.

Understanding the Trade-offs

Each manufacturing pathway presents a different balance of cost, performance, and scalability. Understanding these differences is key to selecting the right bearing.

Machined vs. Molded

The primary trade-off here is between flexibility and volume. Machining is ideal for custom parts and small runs but is more expensive per piece.

Molding requires a significant initial investment in tooling, but for large production runs, it results in a much lower cost per bearing and high repeatability.

Solid PTFE vs. Coated Bearings

This is a fundamental performance trade-off. Solid PTFE bearings offer superior chemical resistance and can function without lubrication, but they have lower compressive strength and can be prone to "creep" or deforming under a sustained heavy load.

PTFE-coated metal bearings provide vastly superior load-carrying capacity and dimensional stability from their metal core, while still offering a low-friction surface. However, the coating is a thin layer that can eventually wear away.

Making the Right Choice for Your Application

Your application's specific demands will determine the optimal manufacturing method.

- If your primary focus is prototyping or a low-volume custom part: Machining from PTFE stock offers the necessary design freedom and avoids high tooling costs.

- If your primary focus is high-volume production of a standard size: Molding is the most cost-effective method for creating thousands of identical parts.

- If your primary focus is high-load capacity and structural rigidity: A PTFE-coated metal-backed bearing provides the strength of metal with the surface properties of Teflon.

Ultimately, understanding how these bearings are made empowers you to specify a component that is perfectly aligned with your project's technical and financial goals.

Summary Table:

| Manufacturing Method | Best For | Key Characteristics |

|---|---|---|

| Machining from Stock | Prototypes, low-volume, custom designs | High design flexibility, no mold cost, higher per-part cost |

| Molding (Compression/Injection) | High-volume production of standard sizes | Low per-part cost, high repeatability, requires upfront tooling investment |

| PTFE Coating on Metal | Applications requiring high strength & low friction | Superior load capacity, thin wear layer, combines metal strength with PTFE surface |

Need a High-Performance PTFE Component?

Choosing the right manufacturing method is critical to your project's success. At KINTEK, we specialize in the precision production of PTFE components, including seals, liners, labware, and custom bearings for the semiconductor, medical, laboratory, and industrial sectors.

We offer expert guidance and custom fabrication from prototypes to high-volume orders, ensuring you get the optimal balance of performance and cost.

Let's discuss your specific requirements. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application