At their core, the key technical features of Teflon (PTFE) backup rings are their exceptional thermal stability, near-universal chemical inertness, and an extremely low coefficient of friction. These properties allow them to provide critical support to primary seals, like O-rings, in demanding high-pressure and high-temperature environments where other materials would quickly fail.

The essential purpose of a Teflon backup ring is not to be the primary seal, but to be a mechanical support component. Its features are engineered to prevent the main O-ring from deforming and extruding into gaps under high pressure, thereby extending the life and reliability of the entire sealing system.

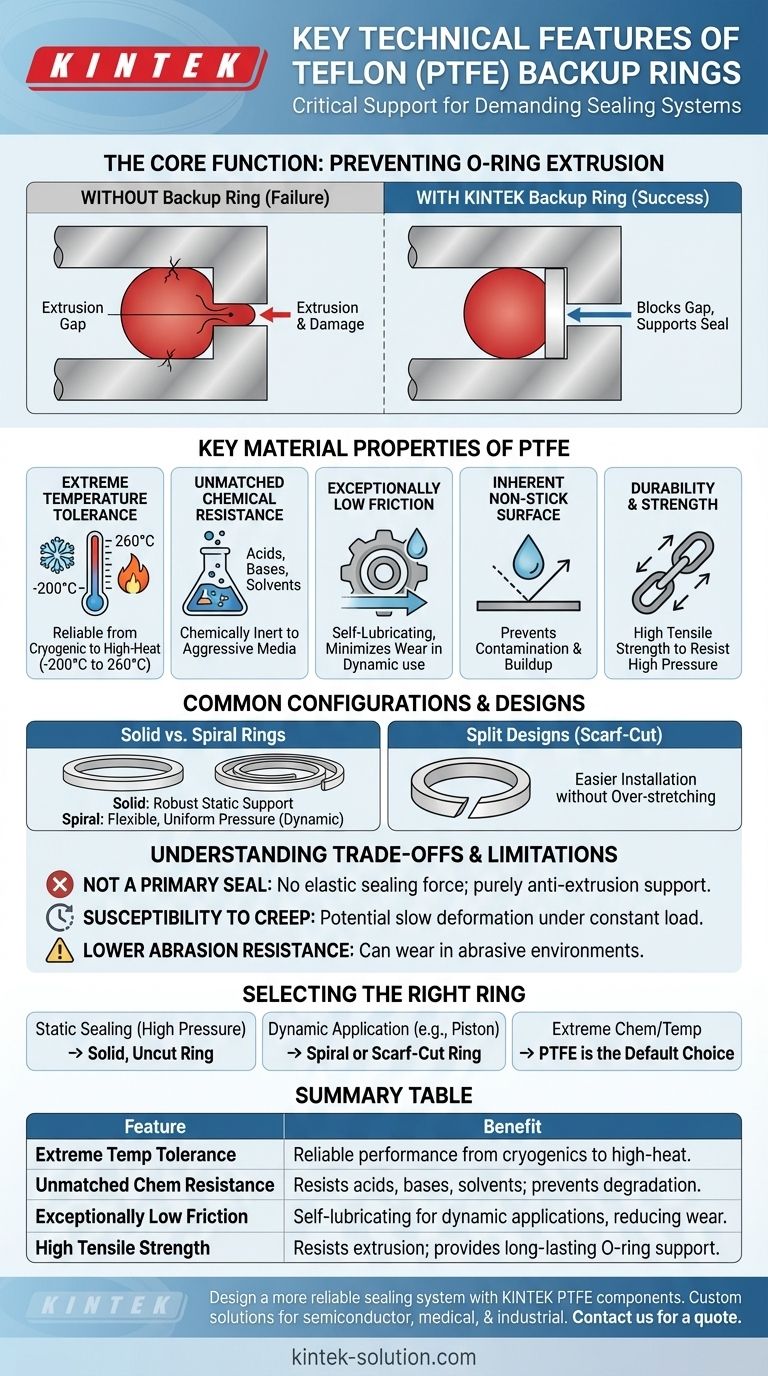

The Core Function: Preventing O-Ring Extrusion

What is Extrusion?

In any sealing application, there is a small gap between moving and stationary parts, known as the extrusion gap.

Under high pressure, a softer rubber O-ring can be forced into this gap. This process, called extrusion, physically damages the O-ring, leading to seal failure.

How a Backup Ring Solves This

A backup ring is a rigid, strong ring installed on the low-pressure side of the O-ring.

Made from a material like PTFE, it is harder than the O-ring and physically blocks the extrusion gap. This allows the O-ring to maintain its shape and sealing force without being damaged by system pressure.

Key Material Properties of PTFE (Teflon)

The choice of PTFE, commonly known by the brand name Teflon, is deliberate. Its unique molecular structure provides a combination of properties ideal for a support role in sealing systems.

Extreme Temperature Tolerance

PTFE backup rings can function reliably across a vast temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This makes them suitable for applications ranging from cryogenic systems to high-temperature industrial processes where standard elastomers would become brittle or degrade.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers available. It offers excellent resistance to aggressive media, including most acids, bases, and solvents.

This ensures the backup ring will not swell, soften, or degrade when exposed to harsh chemicals, maintaining its structural integrity and protective function.

Exceptionally Low Friction

With an extremely low coefficient of friction, PTFE is a self-lubricating material.

This is critical in dynamic applications (e.g., hydraulic cylinders) because it minimizes friction and wear on moving parts, reducing heat generation and improving system efficiency.

Inherent Non-Stick Surface

Almost no substances will adhere to a PTFE surface.

This non-stick property helps prevent system contamination and buildup on the sealing components, which is vital for maintaining performance in clean or sensitive applications.

Durability and Strength

While flexible, PTFE possesses high tensile strength. This strength is what allows it to resist the high pressures that would otherwise cause an O-ring to extrude.

It is also highly durable against aging, UV radiation, and other environmental factors, ensuring a long service life.

Common Configurations and Designs

Backup rings are not a one-size-fits-all component. Their geometry is tailored to specific application demands.

Solid vs. Spiral Rings

Solid rings are simple, single-piece rings that provide robust support in static applications.

Spiral rings are constructed from a coiled ribbon of PTFE. This helical design provides more flexibility, allowing it to conform better to mating surfaces and provide more uniform pressure distribution, which is advantageous in dynamic systems.

Scarf-Cut and Single-Turn Rings

Many designs, such as single-turn or scarf-cut rings, are split. This allows for easier installation over shafts or into piston grooves without over-stretching the material, which could compromise its function.

Understanding the Trade-offs and Limitations

Not a Primary Seal

It is critical to remember that a backup ring is not designed to be a standalone seal. It lacks the elastic properties of a rubber O-ring required to create the initial sealing force. Its function is purely anti-extrusion.

Susceptibility to Creep

Like all fluoropolymers, PTFE can be susceptible to creep, or "cold flow." This is a slow deformation that can occur under a constant, heavy load over time. Proper gland design and sizing are crucial to mitigate this effect.

Lower Abrasion Resistance

Compared to harder plastics or metals, PTFE has relatively low abrasion resistance. In environments with abrasive particulate matter, the ring can wear down, potentially compromising its ability to close the extrusion gap effectively.

Selecting the Right Backup Ring for Your Application

Choosing the correct backup ring depends entirely on the specific demands of your system.

- If your primary focus is high-pressure static sealing: A solid, uncut backup ring provides the most robust resistance to extrusion.

- If your primary focus is a dynamic application (e.g., a piston rod): A spiral or single-turn scarf-cut ring is often preferred for its flexibility and ease of installation.

- If your primary focus is chemical compatibility or extreme temperatures: PTFE is the default choice, as its material properties will ensure survival and performance where other materials cannot.

Ultimately, leveraging the unique features of a Teflon backup ring is a foundational strategy for designing reliable and long-lasting sealing systems.

Summary Table:

| Feature | Benefit |

|---|---|

| Extreme Temperature Tolerance (-200°C to 260°C) | Reliable performance from cryogenics to high-heat processes. |

| Unmatched Chemical Resistance | Resists acids, bases, and solvents, preventing degradation. |

| Exceptionally Low Friction | Self-lubricating for dynamic applications, reducing wear. |

| High Tensile Strength & Durability | Resists extrusion and provides long-lasting support for O-rings. |

Design a more reliable sealing system with KINTEK PTFE components.

Our precision-manufactured Teflon backup rings, seals, and custom labware are engineered to provide the critical support your high-pressure applications demand. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we deliver the material properties you need—from extreme temperature stability to superior chemical resistance.

We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific requirements.

Contact KINTEK today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications