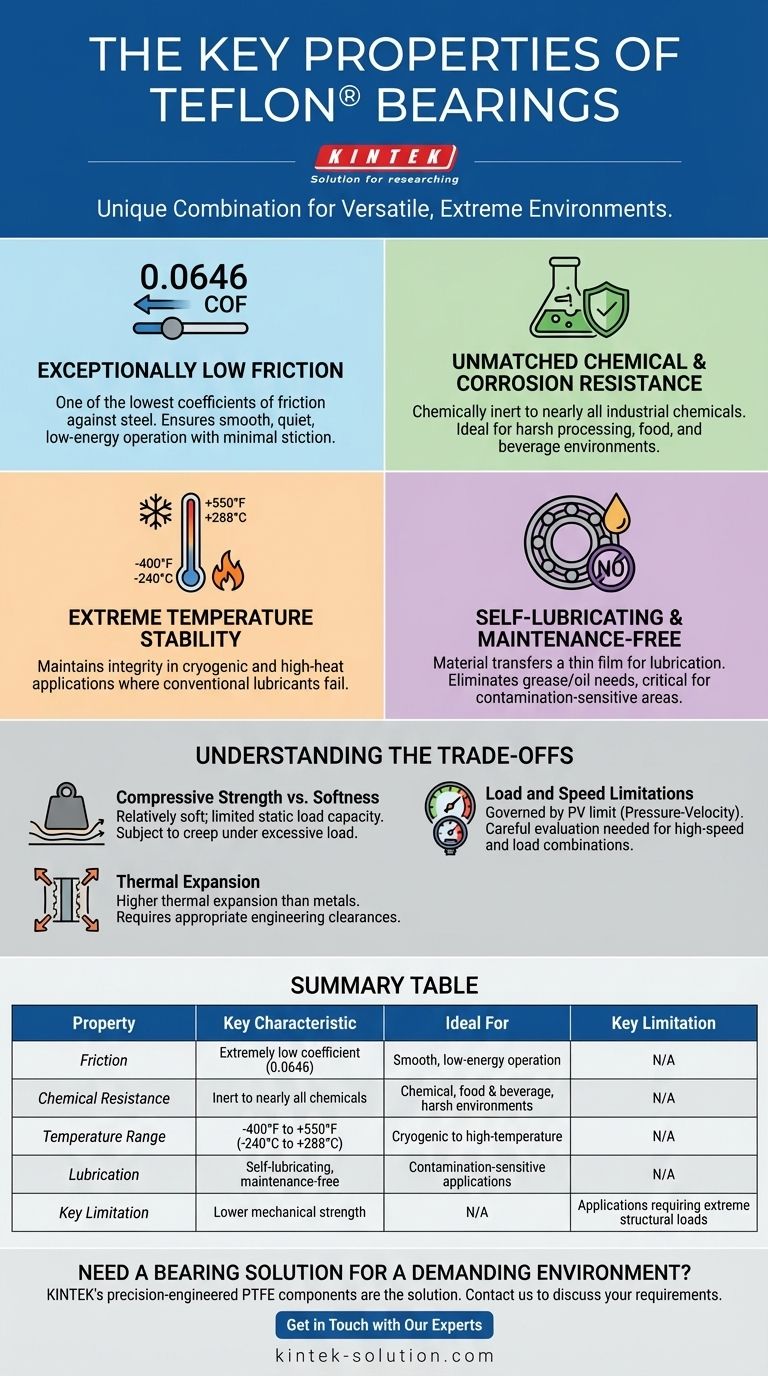

In essence, Teflon bearings are defined by a unique combination of properties that make them exceptionally versatile. Their most critical characteristics are an extremely low coefficient of friction, the ability to operate across a vast range of temperatures, near-total chemical inertness, and a self-lubricating nature that eliminates the need for external grease or oil.

The central value of a Teflon bearing is not just its low friction, but its ability to deliver that performance reliably in extreme environments—chemically harsh, cryogenic, or high-heat—where conventional lubricated metal bearings would fail.

The Core Properties Explained

To understand if a Teflon (PTFE) bearing is the correct solution, we must examine its primary characteristics in the context of real-world applications.

Exceptionally Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material, with a value against steel measured as low as 0.0646.

This "non-stick" quality ensures smooth, consistent, and quiet operation, minimizing the energy required to overcome initial resistance (stiction).

Unmatched Chemical & Corrosion Resistance

Teflon is chemically inert, meaning it is resistant to nearly all industrial chemicals and corrosive substances.

This property makes it an ideal choice for machinery used in chemical processing, food and beverage production, or any environment where exposure to harsh agents would degrade other materials. Only highly reactive alkali metals are known to affect it.

Extreme Temperature Stability

Teflon bearings maintain their structural integrity and performance across an exceptionally wide temperature range, typically from -400°F to +550°F (-240°C to +288°C).

This allows them to function effectively in everything from cryogenic applications to high-temperature industrial ovens, where traditional lubricants would freeze or burn away.

Self-Lubricating & Maintenance-Free

The material itself provides the necessary lubrication by transferring a thin film to the mating surface during operation.

This inherent self-lubricating property eliminates the need for grease or oil, which is critical for reducing maintenance schedules and preventing contamination in sensitive applications like food or medical equipment.

Understanding the Trade-offs

While its primary properties are exceptional, Teflon is a specialized material. Its effectiveness depends on understanding its limitations, which primarily relate to its mechanical strength.

Compressive Strength vs. Softness

Teflon, or PTFE, is a relatively soft fluoropolymer. While it has good compressive strength for a plastic, it cannot handle the extreme static loads that a hardened steel bearing can.

Under excessive load, the material can be subject to creep or cold flow, causing permanent deformation over time. This is a critical factor in design calculations.

Load and Speed Limitations

The performance of any plastic bearing is governed by its PV (Pressure-Velocity) limit. This value represents the maximum combination of load (pressure) and surface speed the bearing can withstand before it fails due to frictional heat buildup.

While Teflon can handle high speeds or moderate loads, applications involving both simultaneously must be carefully evaluated against the material's specific PV rating.

Thermal Expansion

Like most polymers, Teflon has a higher rate of thermal expansion than metals. This means its dimensions will change more significantly with temperature fluctuations.

Designers must account for this by engineering appropriate clearances to prevent the bearing from seizing or becoming too loose within its operational temperature range.

Making the Right Choice for Your Application

Selecting a Teflon bearing is a strategic decision based on the specific demands of your operating environment.

- If your primary focus is operating in corrosive chemical environments: Teflon's inertness makes it an unparalleled choice where metal bearings would quickly fail.

- If your application involves extreme temperatures (high or cryogenic): Its wide stable temperature range provides reliable performance where traditional lubricants would freeze or burn off.

- If your priority is eliminating maintenance and contamination: The self-lubricating nature is ideal for food processing, medical devices, or machinery in inaccessible locations.

- If you are dealing with very high structural loads or impact forces: You must carefully evaluate the bearing's load capacity and consider reinforced PTFE compounds or alternative metal bearings.

Ultimately, choosing a Teflon bearing is an engineering trade-off that favors environmental resilience and low-friction performance over raw load-bearing strength.

Summary Table:

| Property | Key Characteristic | Ideal For |

|---|---|---|

| Friction | Extremely low coefficient of friction (as low as 0.0646) | Smooth, low-energy, quiet operation |

| Chemical Resistance | Inert to nearly all industrial chemicals | Chemical processing, food & beverage, harsh environments |

| Temperature Range | Stable from -400°F to +550°F (-240°C to +288°C) | Cryogenic to high-temperature applications |

| Lubrication | Self-lubricating, maintenance-free | Contamination-sensitive applications (medical, food) |

| Key Limitation | Lower mechanical strength; consider PV limit and creep | Applications requiring extreme structural loads |

Need a Bearing Solution for a Demanding Environment?

If your application demands reliable performance in chemically harsh, high-temperature, or contamination-sensitive environments, KINTEK's precision-engineered PTFE components are the solution.

We specialize in manufacturing high-performance Teflon bearings, seals, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts are fabricated to the highest standards of precision and durability, from prototypes to high-volume production.

Contact us today to discuss your specific requirements and let our team provide a solution that leverages the unique properties of Teflon for your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the composition of expanded PTFE gaskets? Discover the Science Behind Superior Sealing

- How do PTFE seals and rings contribute to environmental compliance? Ensure Leak-Proof Operations

- What factors should be considered when selecting a PTFE lip seal? Optimize Your Sealing System for Reliability

- What are the advantages of mechanical seals with PTFE rings? Superior Chemical & Thermal Resistance

- How are PTFE packings applied in the chemical industry? Ensure Leak-Free Sealing for Hazardous Fluids

- Why are PTFE washers resistant to water and moisture? Unlocking the Power of Hydrophobic Sealing

- How does the large expansion coefficient of PTFE material affect processing? Master Dimensional Stability

- How is graphite filler typically used in PTFE? Enhance Wear Resistance & Self-Lubrication