At its core, environmental compliance hinges on control. PTFE seals and rings are critical components for achieving this control, primarily by preventing the leakage of hazardous materials and enhancing operational efficiency, which directly reduces environmental impact. Their unique material properties ensure they maintain a reliable seal under extreme chemical and thermal stress, making them indispensable for industries facing stringent regulations.

The primary contribution of PTFE to environmental compliance is its exceptional chemical inertness and resilience, which guarantees long-term seal integrity. This directly prevents the uncontrolled release of pollutants, from industrial chemicals to exhaust gases, ensuring operations remain within regulatory limits.

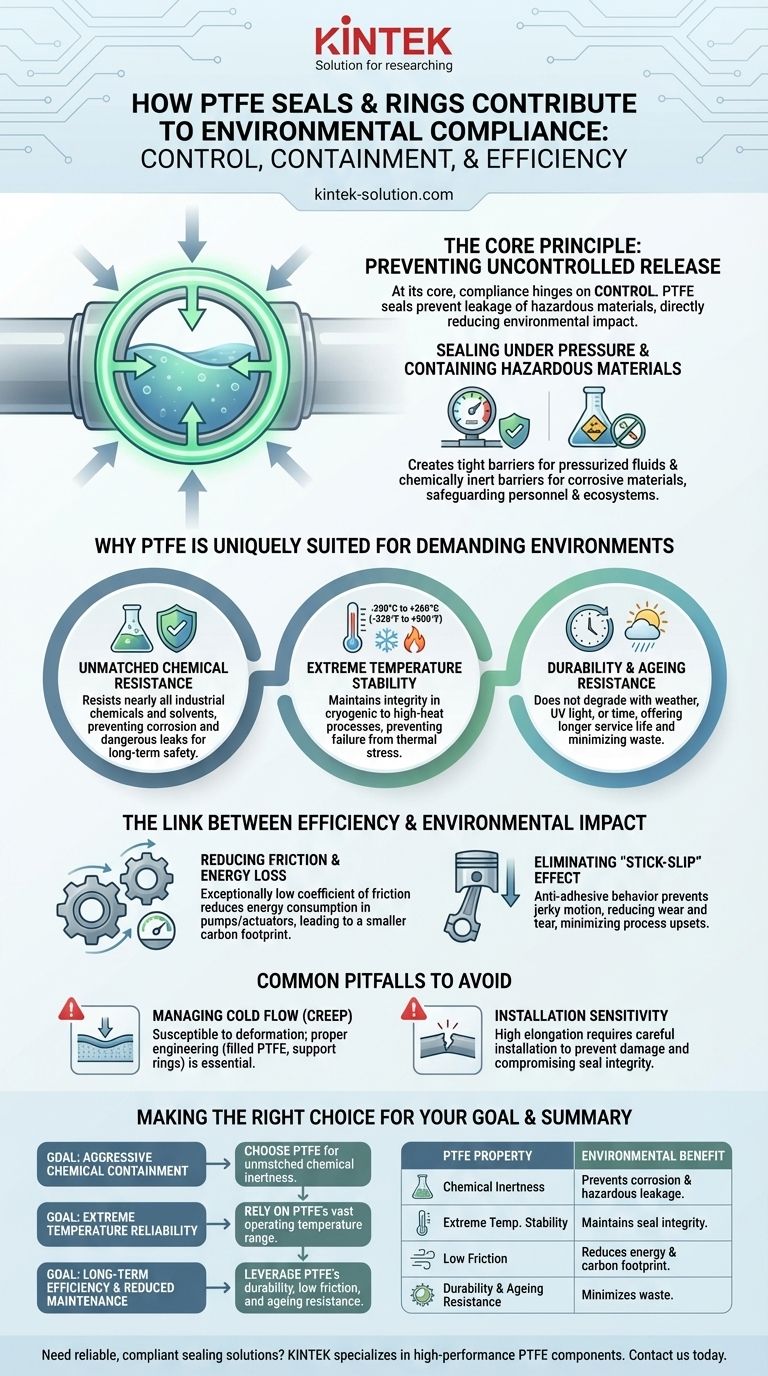

The Core Principle: Preventing Uncontrolled Release

The most direct way any sealing component supports environmental compliance is by keeping substances contained. Leaks, whether small drips or catastrophic failures, are a primary source of environmental contamination.

Sealing Under Pressure

PTFE seals are engineered to create a tight barrier between two mating surfaces, such as pipes or valve components.

They are highly effective at this core function, reliably preventing leaks even when containing pressurized liquids or gases. This ensures that process fluids stay within the system as intended.

Containing Hazardous Materials

In applications from laboratory testing to large-scale chemical processing, PTFE provides a chemically inert barrier.

This prevents corrosive or hazardous materials from degrading the seal and escaping into the environment, safeguarding both personnel and the surrounding ecosystem.

Why PTFE is Uniquely Suited for Demanding Environments

Not all sealing materials are equal. The unique properties of PTFE make it a superior choice for applications where seal failure would have significant environmental consequences.

Unmatched Chemical Resistance

PTFE is resistant to nearly all industrial chemicals and solvents.

This property is crucial in control valves and chemical transfer lines, where material corrosion can lead to seal failure and dangerous leaks. By resisting degradation, PTFE ensures long-term operational safety.

Extreme Temperature Stability

With an effective temperature range from –200°C to +260°C (–328°F to +500°F), PTFE seals do not become brittle in cryogenic applications or soften in high-heat processes.

This stability ensures the seal remains intact across a wide variety of operating conditions, preventing failures caused by thermal stress.

Durability and Ageing Resistance

Unlike many elastomers, PTFE does not degrade with exposure to weather, UV light, or time.

This resistance to ageing means seals have a longer service life, reducing the risk of unexpected failures and minimizing the waste associated with frequent replacements.

The Link Between Efficiency and Environmental Impact

Environmental compliance is not just about preventing spills; it is also about running cleaner, more efficient operations.

Reducing Friction and Energy Loss

PTFE has an exceptionally low coefficient of friction, meaning parts move more freely against it.

In dynamic applications, such as in pumps or actuators, this reduces the energy required for operation. Lower energy consumption translates to a smaller carbon footprint and more sustainable performance.

Eliminating "Stick-Slip" Effect

The anti-adhesive behavior of PTFE prevents the jerky "stick-slip" motion common in other seals.

This leads to smoother, more predictable machine operation, reducing wear and tear and minimizing the potential for process upsets that could have environmental repercussions.

Common Pitfalls to Avoid

While highly effective, the unique properties of PTFE require proper consideration during design and installation to maximize their environmental benefits.

Managing Cold Flow (Creep)

PTFE can be susceptible to "cold flow," where the material slowly deforms under sustained pressure.

Proper engineering, such as using filled PTFE grades or incorporating support rings, is essential to prevent this and ensure a long-lasting, reliable seal.

Installation Sensitivity

The high elongation of PTFE makes fitting easier, but it also means care must be taken not to overstretch or damage the seal during installation.

Improper installation can create a weak point, compromising the seal's integrity and negating its environmental benefits from the start.

Making the Right Choice for Your Goal

Selecting the right seal is a strategic decision in any compliance program. Your primary objective will determine why PTFE is the appropriate choice.

- If your primary focus is containing aggressive chemicals: Choose PTFE for its unmatched chemical inertness, which prevents seal degradation and leakage.

- If your primary focus is reliability in extreme temperatures: Rely on PTFE's vast operating temperature range to ensure seal integrity in both cryogenic and high-heat systems.

- If your primary focus is long-term efficiency and reduced maintenance: Leverage PTFE's durability, low-friction surface, and resistance to ageing to minimize energy use and prevent unexpected failures.

Ultimately, specifying PTFE seals is a proactive measure for robust, long-term environmental and operational risk management.

Summary Table:

| PTFE Property | Environmental Benefit |

|---|---|

| Chemical Inertness | Prevents corrosion and leakage of hazardous substances |

| Extreme Temperature Stability | Maintains seal integrity from -200°C to +260°C |

| Low Friction | Reduces energy consumption and carbon footprint |

| Durability & Ageing Resistance | Minimizes waste from frequent replacements |

Need reliable, compliant sealing solutions? KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services (from prototypes to high-volume orders) ensure your operations meet environmental standards while maximizing efficiency. Contact us today to discuss your specific requirements and let us help you achieve leak-proof, sustainable performance.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments