In the chemical industry, PTFE packings are primarily used to create a reliable seal around the moving shafts of pumps and valves. This application is critical for preventing the leakage of aggressive and often hazardous fluids, especially in high-pressure and high-temperature environments, thereby ensuring both operational safety and equipment integrity.

The core challenge in chemical processing is containing corrosive materials within dynamic systems. PTFE, in its various forms, serves as the premier solution not just for packing, but for comprehensive chemical isolation, prized for its near-universal chemical inertness and exceptionally low friction.

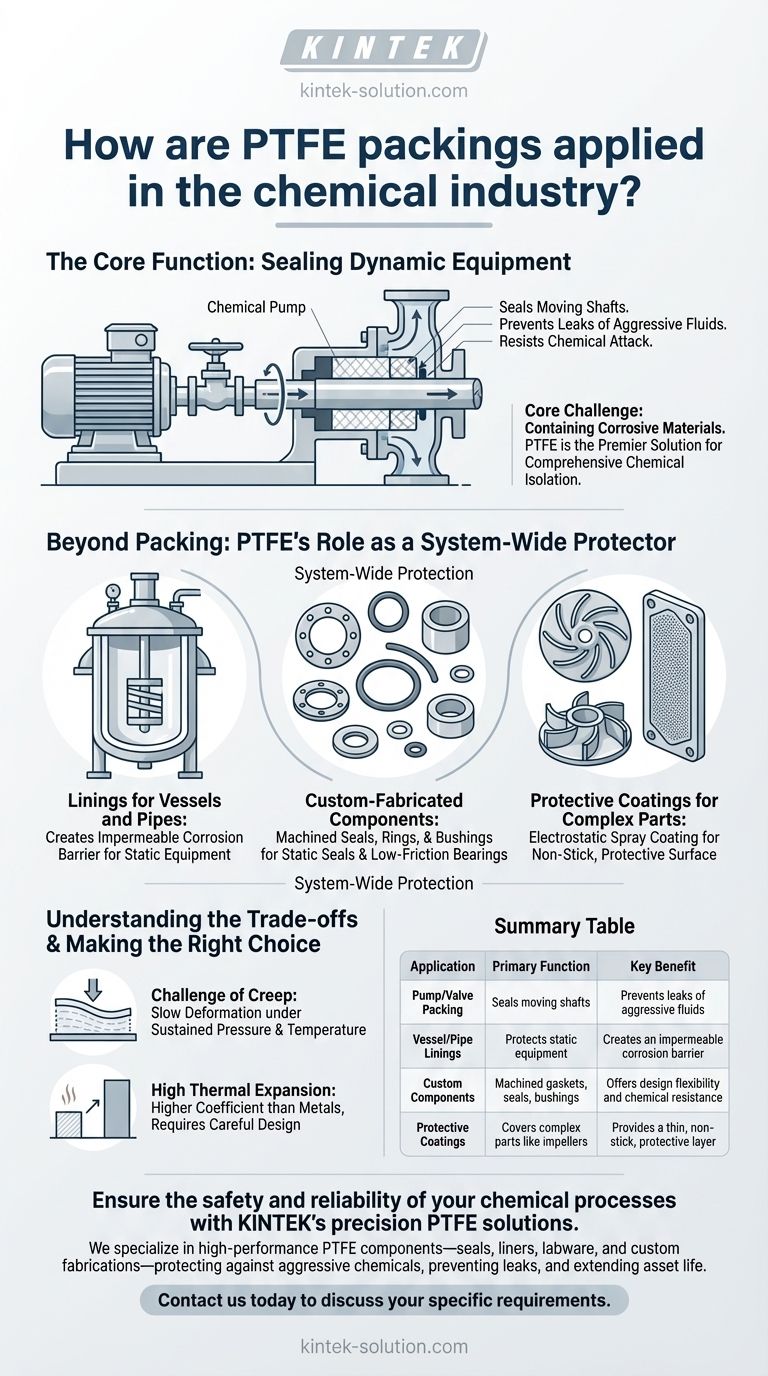

The Core Function: Sealing Dynamic Equipment

In any chemical plant, the points where moving parts enter a contained system—such as the shaft of a pump or the stem of a valve—are the most vulnerable to leaks. PTFE packings are engineered specifically to solve this problem.

Why Pumps and Valves are Critical Points

Pumps and valves are the workhorses of fluid transfer. Their internal components are constantly in motion, creating a significant challenge for maintaining a perfect seal between the moving shaft and the stationary housing.

A failure at this interface can lead to dangerous leaks, environmental contamination, and costly downtime.

How PTFE Packing Creates a Seal

PTFE packing is typically a braided material that is inserted into the stuffing box of a pump or valve. When compressed, it expands radially to form a tight, durable seal against the shaft and the housing wall.

Its primary function is to contain the process fluid while withstanding the friction and heat generated by the moving shaft.

Resisting Aggressive Chemical Attack

The standout feature of PTFE is its remarkable chemical resistance. It is virtually inert to almost all industrial chemicals, acids, and caustics, preventing degradation that would cause other sealing materials to fail quickly.

This inertness ensures a long service life and reliable performance, even when handling the most corrosive substances.

Beyond Packing: PTFE's Role as a System-Wide Protector

While "packing" is a specific application, the material properties of PTFE make it a fundamental component for protection throughout the chemical industry, applied in several distinct forms.

Linings for Vessels and Pipes

For large, static equipment like reaction vessels, storage tanks, and pipelines, thick PTFE sheets are often used as a bonded lining.

This application creates an impermeable barrier that protects the structural metal of the equipment from chemical corrosion, dramatically extending its lifespan and purity of the product.

Custom-Fabricated Components

PTFE is also supplied in solid forms like rods, bars, and sheets. These are easily machined into custom components that require high chemical resistance.

Common examples include gaskets, custom seals, rings, washers, and bushings, which are used to create static seals between flanges or act as low-friction bearing surfaces.

Protective Coatings for Complex Parts

For components with complex geometries, like impellers, diaphragms, and heat exchangers, a PTFE coating is often applied.

This is done using methods like electrostatic spraying, where negatively charged PTFE particles adhere to a grounded part, which is then cured at high temperatures. This creates a thin, protective, and non-stick surface.

Understanding the Trade-offs

No material is without its limitations. A comprehensive understanding requires acknowledging the engineering trade-offs associated with PTFE.

The Challenge of Creep

Under sustained pressure and temperature, PTFE can be susceptible to "creep" or cold flow. This means the material can slowly deform over time, potentially reducing the effectiveness of a seal if not accounted for in the design.

High Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. Engineers must carefully design components and seals to accommodate this expansion and contraction to maintain sealing integrity across a range of operating temperatures.

Specialized Processing

Applying PTFE coatings or properly installing packings and linings requires specialized knowledge and equipment. The initial cost and complexity can be higher than for other materials, but this is typically offset by reduced maintenance and longer equipment life.

Making the Right Choice for Your Goal

Selecting the correct form of PTFE is essential for maximizing performance and ensuring the safety of your chemical process.

- If your primary focus is sealing dynamic components (pumps, valves): Braided PTFE packing is the industry standard for preventing leaks of corrosive fluids under pressure.

- If your primary focus is protecting large, static equipment (tanks, reactors): A bonded PTFE lining provides the most robust and effective large-scale corrosion barrier.

- If your primary focus is creating custom static seals or low-friction parts: Machining gaskets, rings, or bushings from solid PTFE rods or sheets offers maximum design flexibility.

Ultimately, leveraging the correct form of PTFE is essential for guaranteeing the safety, reliability, and efficiency of critical chemical processes.

Summary Table:

| Application | Primary Function | Key Benefit |

|---|---|---|

| Pump/Valve Packing | Seals moving shafts | Prevents leaks of aggressive fluids |

| Vessel/Pipe Linings | Protects static equipment | Creates an impermeable corrosion barrier |

| Custom Components | Machined gaskets, seals, bushings | Offers design flexibility and chemical resistance |

| Protective Coatings | Covers complex parts like impellers | Provides a thin, non-stick, protective layer |

Ensure the safety and reliability of your chemical processes with KINTEK's precision PTFE solutions.

We specialize in manufacturing high-performance PTFE components—including seals, liners, labware, and custom fabrications—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment is protected against the most aggressive chemicals, helping you prevent leaks, reduce downtime, and extend asset life.

Contact us today to discuss your specific requirements, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation