PTFE gaskets provide exceptional electrical insulation by creating a highly stable and non-conductive barrier. Their effectiveness comes not just from blocking electricity, but from maintaining this core property reliably across a wide range of harsh operating conditions, including extreme temperatures, chemical exposure, and moisture.

The true value of PTFE as an electrical insulator isn't just its high electrical resistance. It's the material's unique ability to sustain that resistance without degrading when exposed to the chemical, thermal, and mechanical stresses that cause other insulators to fail.

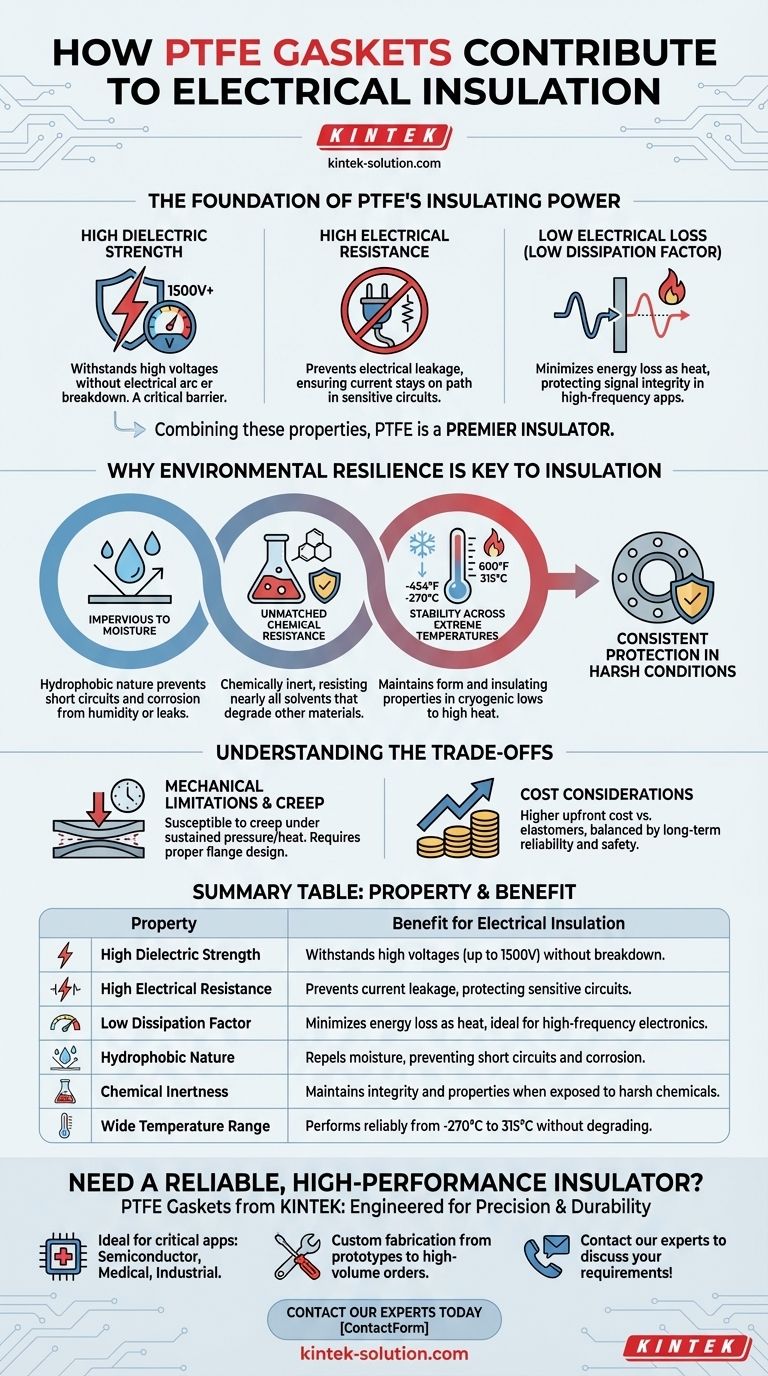

The Foundation of PTFE's Insulating Power

The core insulating capability of Polytetrafluoroethylene (PTFE) is rooted in its unique molecular structure and the resulting electrical properties.

Understanding Dielectric Strength

Dielectric strength is a measure of a material's ability to withstand a high voltage before it breaks down and allows current to pass through. PTFE has an extremely high dielectric strength.

This means it can insulate components operating at significant voltages without risk of an electrical arc or short circuit. For example, it can resist high voltages, in some cases up to 1500 volts, without current leakage.

High Electrical Resistance

Closely related to dielectric strength is PTFE's very high electrical resistance. It is a premier insulating material that fundamentally opposes the flow of electricity.

This property is critical for preventing electrical leakage in sensitive circuits, ensuring that current stays on its intended path and does not interfere with nearby components.

Low Electrical Loss

PTFE also exhibits very low electrical loss, or a low dissipation factor. This is especially important in high-frequency applications.

It ensures that minimal electrical energy is lost as heat when passing through or near the material, protecting the integrity of signals in communications equipment and other delicate electronic devices.

Why Environmental Resilience is Key to Insulation

An insulator is only as good as its ability to perform in a real-world environment. This is where PTFE's secondary characteristics become just as important as its primary electrical properties.

Impervious to Moisture

PTFE is hydrophobic, meaning it repels water. Moisture is a primary cause of insulation failure and short circuits in electrical systems.

By preventing moisture from penetrating an enclosure, a PTFE gasket directly protects sensitive electronics from electrical damage and corrosion.

Unmatched Chemical Resistance

PTFE is famous for being chemically inert and is impervious to nearly all solvents and chemicals.

In industrial settings, exposure to harsh chemicals can degrade other insulating materials, compromising their electrical properties. PTFE gaskets maintain their integrity, ensuring long-term, reliable insulation.

Stability Across Extreme Temperatures

PTFE maintains its physical form and insulating properties over an incredibly wide temperature range, from cryogenic lows (-454°F / -270°C) to high heat (600°F / 315°C).

This thermal stability ensures that the gasket will not become brittle, melt, or deform, guaranteeing consistent electrical protection whether the equipment is in a frozen environment or a hot engine bay.

Understanding the Trade-offs

While PTFE is a superior insulator, it is not the perfect material for every situation. Acknowledging its limitations is crucial for proper design.

Mechanical Limitations and Creep

PTFE is a relatively soft material and can be susceptible to creep, or cold flow. Under sustained high pressure and temperature, the material can slowly deform over time.

This can potentially compromise the integrity of a seal if the joint is not designed correctly. Proper flange design and torque specifications are essential to mitigate this effect.

Cost Considerations

PTFE is a high-performance polymer and is generally more expensive than common elastomer gaskets like nitrile or EPDM.

The higher upfront cost must be weighed against the long-term benefits of superior reliability, reduced maintenance, and enhanced safety in demanding applications.

Making the Right Choice for Your Application

Selecting the right gasket material requires balancing performance requirements with environmental conditions and budget.

- If your primary focus is safety and reliability in harsh environments: PTFE is the definitive choice due to its unmatched chemical and thermal stability, which guarantees long-term insulation.

- If your primary focus is protecting sensitive, high-frequency electronics: PTFE's high dielectric strength and low electrical loss prevent signal interference and energy waste, making it ideal.

- If your primary focus is a simple, low-cost application with no chemical or thermal stress: A standard elastomer gasket may be a sufficient and more economical choice.

By understanding these properties, you can confidently select the right material to ensure the safety and longevity of your electrical system.

Summary Table:

| Property | Benefit for Electrical Insulation |

|---|---|

| High Dielectric Strength | Withstands high voltages (up to 1500V) without breakdown or arcing. |

| High Electrical Resistance | Prevents current leakage, protecting sensitive circuits. |

| Low Dissipation Factor | Minimizes energy loss as heat, ideal for high-frequency electronics. |

| Hydrophobic Nature | Repels moisture, preventing short circuits and corrosion. |

| Chemical Inertness | Maintains integrity and insulating properties when exposed to harsh chemicals. |

| Wide Temperature Range | Performs reliably from -270°C to 315°C without degrading. |

Need a reliable, high-performance insulator for your critical application?

PTFE gaskets from KINTEK are engineered for precision and durability, offering unmatched electrical insulation in the most demanding environments—from semiconductor manufacturing and medical devices to industrial and laboratory equipment.

We specialize in custom fabrication, delivering everything from prototypes to high-volume orders with a focus on quality and performance.

Contact our experts today to discuss your specific requirements and ensure the safety and longevity of your electrical systems!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries commonly use PTFE bushings, and why? Solve Critical Engineering Challenges

- What are some common structural types of PTFE gaskets? Choose the Right Seal for Your Application

- What are the key properties of virgin PTFE? Unlock Extreme Chemical & Thermal Resistance

- What printing applications are Teflon sheets suitable for? Achieve Flawless Heat Transfers

- What types of PTFE products are available for fluid handling solutions? Your Guide to High-Purity Components

- How is a piston seal constructed? A Guide to Dynamic, Pressure-Energized Sealing

- What maintenance characteristics do PTFE sliding pipe supports have? A Zero-Maintenance Solution for Piping Systems

- What types of cutting tools are recommended for machining PTFE? Achieve Clean Cuts and Tight Tolerances