In heat press printing, Teflon sheets are essential protective tools. They are primarily used for heat transfer vinyl (HTV) and sublimation applications. Their uniquely non-stick and heat-resistant surface protects both the garment and the heat press itself, ensuring a clean and professional transfer onto materials like apparel, ceramics, and paper.

A Teflon sheet acts as a critical protective barrier in heat press applications. Its purpose is not to be part of the final print, but to enable a flawless transfer by preventing scorching, sticking, and ink contamination between projects.

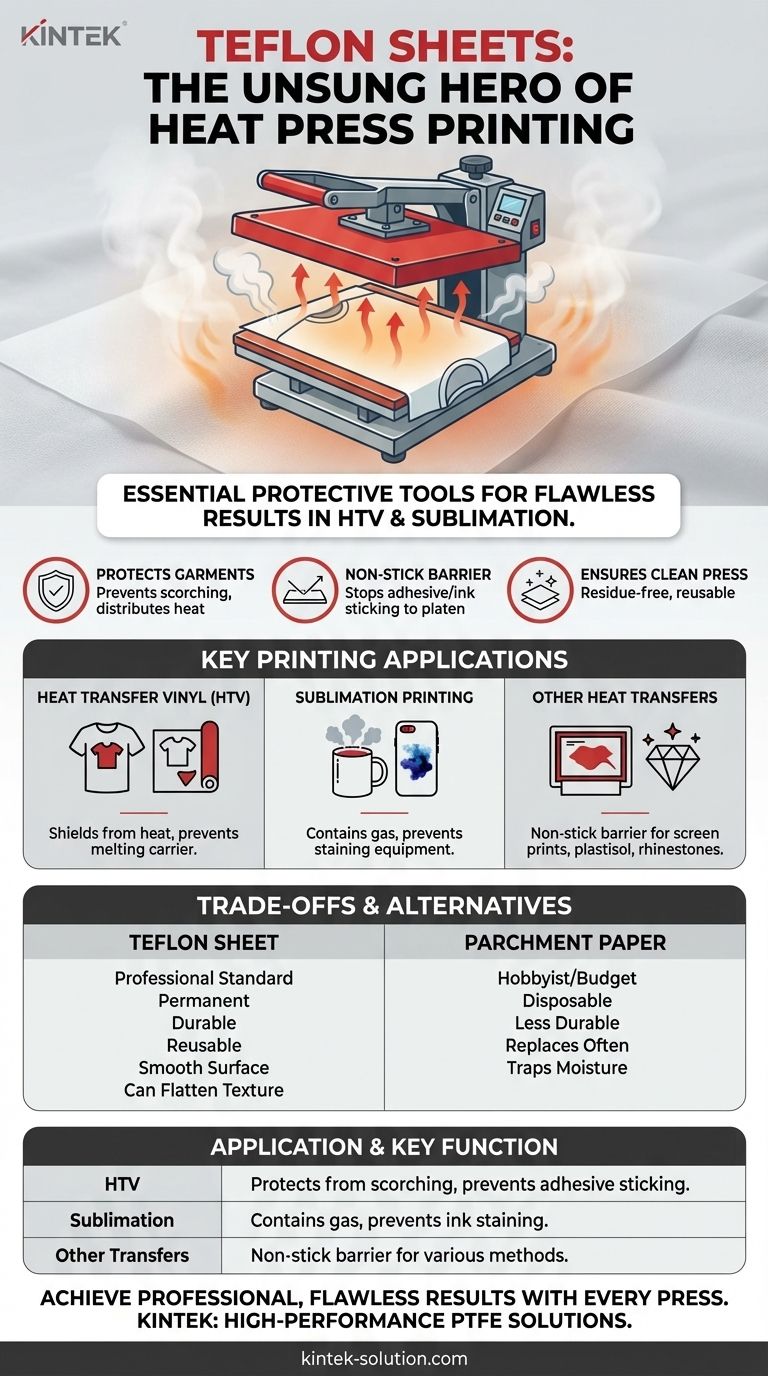

The Core Function of a Teflon Sheet in Heat Pressing

A Teflon sheet, technically made from Polytetrafluoroethylene (PTFE), is a reusable cover sheet placed between your design and the hot upper platen of your heat press. Its role is simple but indispensable.

Protecting Your Garment

The most common reason to use a Teflon sheet is to protect the item you are printing on. The intense, direct heat from a press can easily scorch or leave a faint yellowing on sensitive fabrics. The sheet distributes heat more evenly, acting as a buffer to prevent this damage.

Creating a Non-Stick Barrier

The signature non-stick quality of Teflon is crucial. For HTV projects, it prevents any excess adhesive from oozing out and sticking to the heat platen. For sublimation, it stops ink that has turned to gas from bleeding through the paper and permanently staining your equipment.

Ensuring a Clean Press

By preventing ink and adhesive from contaminating the heat platen, the Teflon sheet ensures that residue from one job doesn't get accidentally transferred to the next. This simple step saves you from costly and frustrating mistakes.

Key Printing Applications Explained

While versatile, Teflon sheets excel in specific heat-based printing methods where protection from direct heat and sticking is paramount.

Heat Transfer Vinyl (HTV)

In HTV applications, you place the Teflon sheet directly over the vinyl's plastic carrier sheet. It serves two functions: it shields the garment from the direct heat surrounding the design, and it prevents the carrier sheet from potentially melting onto your press if the temperature is too high.

Sublimation Printing

During sublimation, special ink is converted into a gas that permeates the fibers of polyester or poly-coated materials. A Teflon sheet is vital to contain this gas, preventing it from staining the upper platen and ensuring all the ink is directed into the target item.

Other Heat Transfer Methods

Teflon sheets are also valuable for other heat-applied graphics. This includes screen-printed transfers, plastisol transfers, and even applying rhinestone embellishments, where a non-stick protective layer improves consistency and protects the equipment.

Understanding the Trade-offs and Alternatives

While highly effective, it's important to understand the context of using a Teflon sheet and when an alternative might be considered.

Potential Impact on Texture

Because a Teflon sheet has a very smooth, slightly glossy surface, it can sometimes flatten the texture of certain specialty materials. For HTV products like flock or puff vinyl, the smooth pressure can diminish the desired effect.

The Parchment Paper Alternative

The most common alternative is silicone-treated parchment paper. It is less expensive and disposable, making it a viable option for hobbyists or infrequent use. However, it is far less durable, must be replaced often, and can sometimes trap moisture, which can interfere with the curing process.

Why Teflon is the Professional Standard

Unlike parchment paper, a Teflon sheet is a permanent tool. It is tear-resistant, can be wiped clean after every use, and will last for thousands of presses. This durability and reliability make it the standard choice for any professional or serious printing business.

Making the Right Choice for Your Goal

Selecting the right protective cover is a small decision that has a significant impact on the quality and consistency of your work.

- If your primary focus is professional apparel decoration: A Teflon sheet is a non-negotiable investment for consistent, high-quality HTV and sublimation results.

- If you are a hobbyist or have a tight budget: You can begin with high-quality parchment paper, but plan to upgrade to a Teflon sheet for better durability and scorch protection as you print more.

- If you are working with specialty textured vinyl: Test your press with and without a Teflon sheet on a scrap piece to see if it flattens the desired finish; a craft paper cover may be a better choice in these specific cases.

Ultimately, incorporating a Teflon sheet into your workflow is a fundamental step toward achieving reliable and professional-grade heat transfers.

Summary Table:

| Application | Key Function |

|---|---|

| Heat Transfer Vinyl (HTV) | Protects garment from scorching, prevents adhesive sticking to press. |

| Sublimation Printing | Contains sublimation gas, prevents ink from staining equipment. |

| Other Heat Transfers | Provides a non-stick barrier for transfers, rhinestones, and more. |

Achieve professional, flawless results with every press. KINTEK manufactures high-performance PTFE (Teflon) sheets and components designed for the demanding needs of the printing, industrial, and specialized manufacturing industries. Our sheets offer superior heat resistance and a guaranteed non-stick surface for maximum durability and print quality. Whether you need a standard size or a custom-fabricated solution for your specific equipment, we provide precision production from prototypes to high-volume orders.

Contact KINTEK today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability