Ultimately, PTFE sliding pipe supports are maintenance-free. Their core material, Polytetrafluoroethylene (PTFE), is inherently self-lubricating, meaning it requires no external greasing or servicing to perform its function over its entire lifecycle. This unique characteristic stems from its fundamental material properties.

The core reason for the zero-maintenance nature of PTFE supports lies in the material's ability to be self-lubricating while also absorbing minor contaminants. This design eliminates the most common failure points and service requirements seen in other types of bearings.

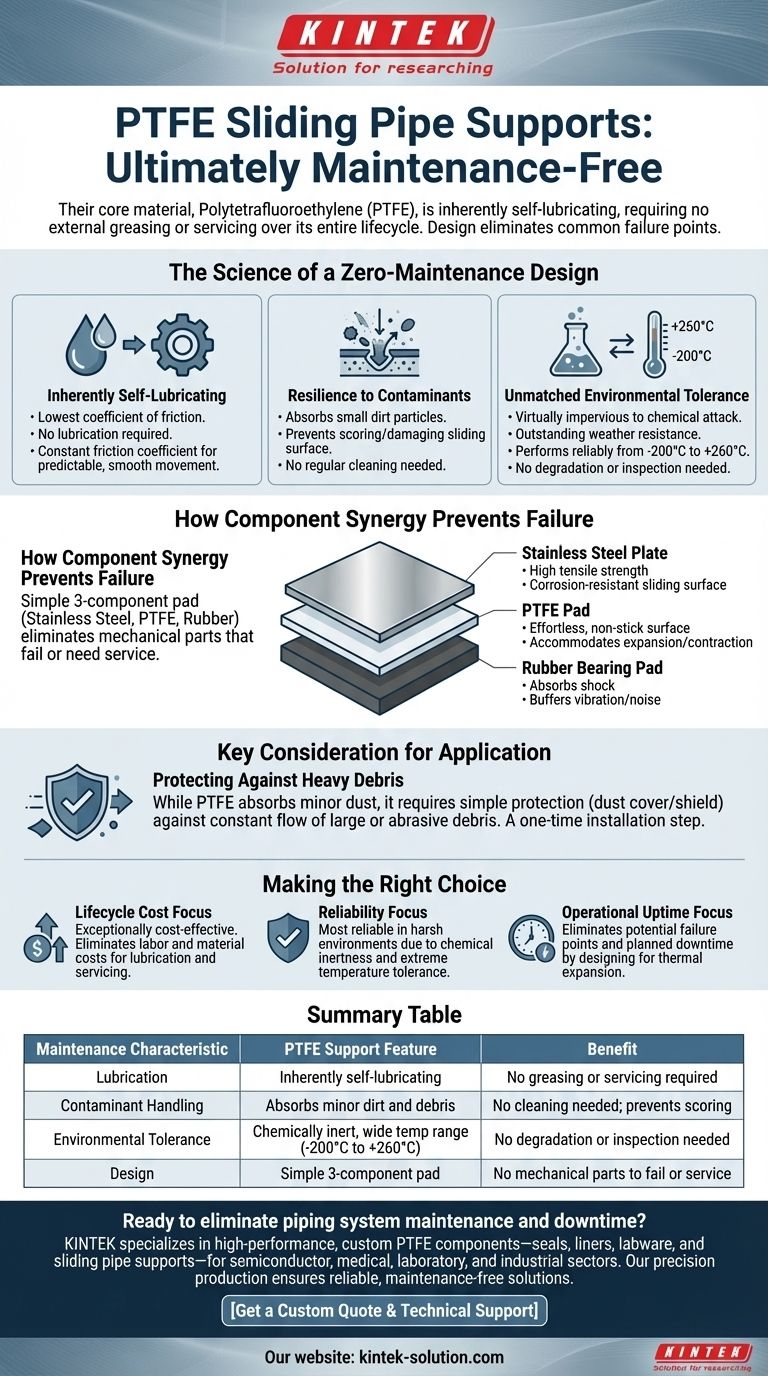

The Science of a Zero-Maintenance Design

The reliability of PTFE pipe supports is not an accident; it is the direct result of the material's exceptional properties and a simple, effective design. Understanding these factors is key to trusting their long-term performance.

Inherently Self-Lubricating

PTFE has the lowest coefficient of friction of any known solid material. This eliminates the need for lubrication, which is a primary maintenance activity for other types of supports.

The friction coefficient remains constant, ensuring predictable and smooth movement even under the worst-case operational conditions.

Resilience to Contaminants

A remarkable characteristic of PTFE is its ability to handle environmental debris. Small dirt particles are absorbed directly into the soft material, preventing them from scoring or damaging the sliding surface.

This removes the need for regular cleaning that is often required to prevent abrasion and seizure in traditional mechanical supports.

Unmatched Environmental Tolerance

PTFE is virtually impervious to chemical attack and exhibits outstanding resistance to weathering. This prevents the material degradation that would typically necessitate inspection and replacement.

Furthermore, it performs reliably across an enormous temperature range, from –200° C to +260° C (–328° F to +500° F), making it suitable for almost any industrial environment.

How Component Synergy Prevents Failure

The design of a typical PTFE sliding pad is simple and robust, using a synergy of materials to eliminate potential points of failure.

The Three Core Components

A standard support consists of three parts: a stainless steel plate, a PTFE pad, and a rubber bearing pad. The PTFE is bonded to the rubber.

Purpose of Each Component

The stainless steel plate provides high tensile strength and a corrosion-resistant sliding surface. The rubber pad absorbs shock and buffers against vibration and noise.

The PTFE pad provides the effortless, non-stick surface that allows the pipe to expand and contract without strain. This simple construction is easy to fabricate and install, further reducing costs.

The Key Consideration for Application

While these supports are rightly called maintenance-free, there is one crucial environmental factor to consider during the design and installation phase.

Protecting Against Heavy Debris

The references note that "simple protection is required against significant dirt increases." This is the only real caveat.

While the PTFE pad can absorb minor dust and dirt, it is not designed to function in an environment with a constant flow of large or abrasive debris (like sand or gravel).

In such high-contamination areas, a simple dust cover or shield should be installed to protect the sliding surfaces, ensuring the support's longevity. This is a one-time installation step, not ongoing maintenance.

Making the Right Choice for Your Goal

The low-maintenance nature of PTFE supports makes them a superior choice for a wide range of applications, but your specific goal will determine the key takeaway.

- If your primary focus is lifecycle cost: These supports are exceptionally cost-effective due to the complete elimination of labor and material costs associated with lubrication and servicing.

- If your primary focus is reliability in a harsh environment: PTFE's chemical inertness and extreme temperature tolerance make it the most reliable option where other materials would quickly degrade and fail.

- If your primary focus is operational uptime: By designing for thermal expansion with a maintenance-free component, you eliminate a potential point of failure and a reason for planned downtime.

By understanding these principles, you can confidently specify PTFE supports as a true "set-and-forget" solution for accommodating pipe movement.

Summary Table:

| Maintenance Characteristic | PTFE Support Feature | Benefit |

|---|---|---|

| Lubrication | Inherently self-lubricating | No greasing or servicing required |

| Contaminant Handling | Absorbs minor dirt and debris | No cleaning needed; prevents scoring |

| Environmental Tolerance | Chemically inert, wide temperature range (-200°C to +260°C) | No degradation or inspection needed |

| Design | Simple 3-component pad (Stainless Steel, PTFE, Rubber) | No mechanical parts to fail or service |

Ready to eliminate piping system maintenance and downtime?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, labware, and sliding pipe supports—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures you get a reliable, maintenance-free solution tailored to your specific needs, from prototypes to high-volume orders.

Contact us today to discuss how our PTFE components can enhance your system's reliability and reduce your total lifecycle costs.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance