In fluid handling, Polytetrafluoroethylene (PTFE) is engineered into a range of critical components for high-purity and chemically aggressive applications. These core products include control components like check valves and ball valves, system-building elements like connectors, and sealing solutions derived from Expanded PTFE (ePTFE). Their selection is driven by a need for exceptional material purity and resistance to corrosion.

The fundamental value of PTFE products in fluid handling lies in their unparalleled chemical inertness and inherent purity. This makes them the default material for systems that cannot tolerate contamination or material degradation from harsh media.

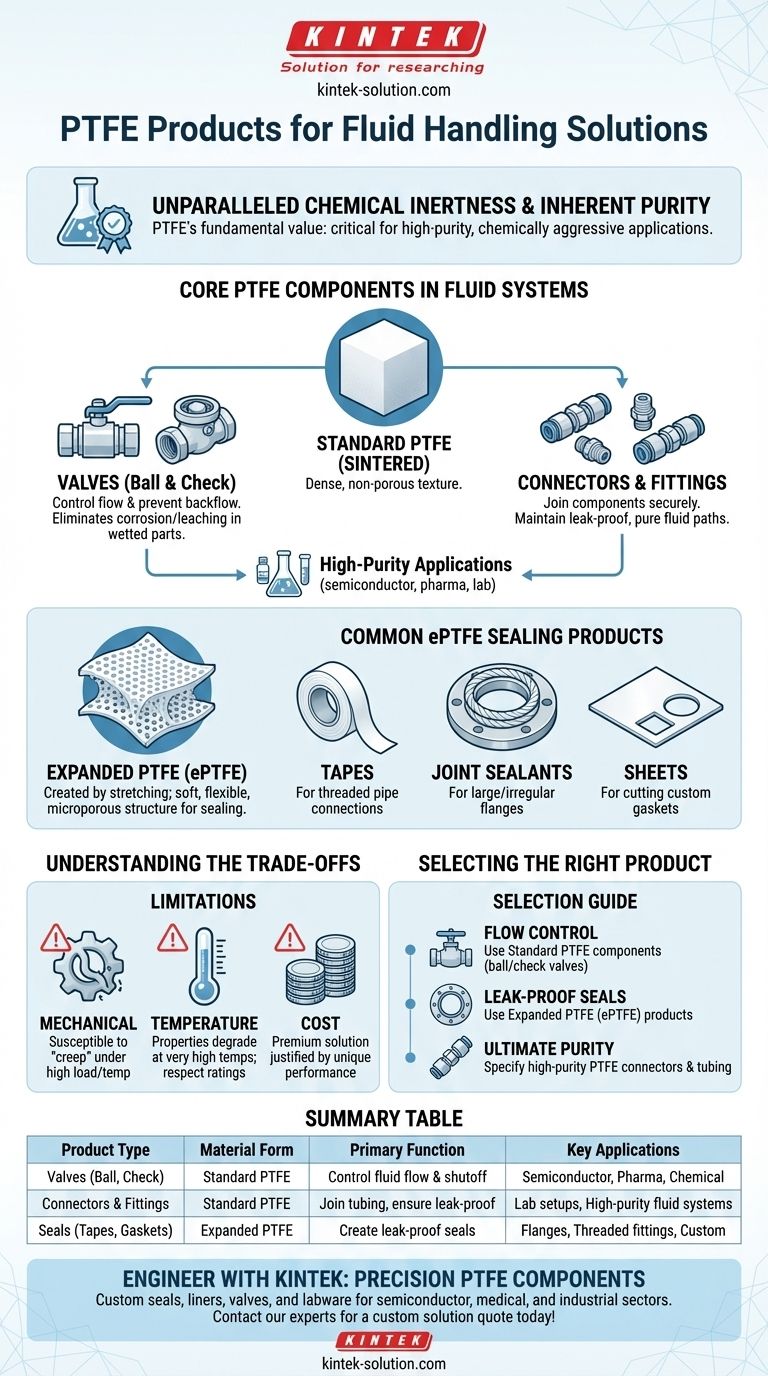

Core PTFE Components in Fluid Systems

The most common PTFE products are designed for direct fluid contact and control. They are machined from solid, or "standard," PTFE and valued for their smooth, non-contaminating surfaces.

PTFE Valves (Ball and Check)

Valves are essential for controlling the flow within a system. Ball valves provide simple and reliable on/off control, while check valves are used to prevent backflow, ensuring the fluid moves in only one direction. Using PTFE for the valve body and wetted parts eliminates the risk of corrosion or leaching that can occur with metal components.

PTFE Connectors and Fittings

Connectors and fittings are the building blocks used to join tubing and components. PTFE-based designs create secure, leak-proof connections that maintain the purity of the fluid path. They are critical in semiconductor, pharmaceutical, and laboratory applications where even trace contamination is unacceptable.

Differentiating Standard vs. Expanded PTFE (ePTFE)

While both are the same polymer, their physical forms are engineered for different tasks. Understanding this distinction is key to proper application.

Standard (Sintered) PTFE

This is the solid, dense, non-porous form of the material. It is used to manufacture the rigid components discussed above, like valve bodies and connectors. Its primary characteristics are its rigidity and extremely low-friction surface.

Expanded PTFE (ePTFE)

This is a soft, flexible, and porous material created by stretching PTFE under specific conditions. This process creates a microporous structure of fibers and nodes, giving it excellent compressive and sealing properties.

Common ePTFE Sealing Products

Unlike the fluid-directing components made from standard PTFE, ePTFE is almost exclusively used for sealing. Common products include ePTFE tapes for sealing threaded pipe connections, ePTFE joint sealants (a rope-like gasket) for large or irregular flanges, and ePTFE sheets for cutting custom gaskets.

Understanding the Trade-offs

While PTFE is a superior material for many applications, it's essential to be aware of its limitations to ensure system reliability.

Mechanical Limitations

PTFE is a relatively soft polymer. Under high mechanical loads or elevated temperatures, it can be susceptible to "creep" or "cold flow," where the material slowly deforms over time. This must be considered in high-pressure system design.

Temperature Range

While PTFE has a wide operating temperature range, its mechanical properties degrade significantly at very high temperatures. System designers must respect the pressure-temperature ratings specified by the manufacturer.

Cost Factor

PTFE components are a premium solution. Their cost is higher than that of many common polymers and metals, which is justified by their unique performance in applications where other materials would quickly fail.

Selecting the Right PTFE Product for Your Application

Choosing the correct product type comes down to its function within the fluid handling system.

- If your primary focus is controlling or directing fluid flow: Look to standard PTFE components like ball valves for shutoff control and check valves to prevent backflow.

- If your primary focus is creating leak-proof seals between components: Utilize Expanded PTFE (ePTFE) products such as joint sealants for flanges or tapes for threaded fittings.

- If your primary focus is ensuring ultimate purity and media compatibility: Specify high-purity PTFE connectors and tubing to construct the entire wetted fluid path.

By understanding the distinct roles of standard and expanded PTFE, you can engineer a fluid handling system with uncompromising integrity and reliability.

Summary Table:

| Product Type | Material Form | Primary Function | Key Applications |

|---|---|---|---|

| Valves (Ball, Check) | Standard PTFE | Control fluid flow direction and shutoff | Semiconductor, Pharmaceutical, Chemical Processing |

| Connectors & Fittings | Standard PTFE | Join tubing/components, ensure leak-proof connections | Laboratory setups, High-purity fluid systems |

| Seals (Tapes, Gaskets) | Expanded PTFE (ePTFE) | Create leak-proof seals between components | Flanges, Threaded fittings, Custom gaskets |

Engineer a leak-proof, contamination-free fluid handling system with KINTEK's precision PTFE components.

Whether you are designing for the semiconductor, medical, laboratory, or industrial sector, KINTEK manufactures high-purity PTFE and ePTFE products—including custom seals, liners, valves, and labware—to meet your exact specifications. From prototypes to high-volume orders, we prioritize precision production to ensure chemical inertness and system reliability.

Contact our experts today to discuss your fluid handling challenges and receive a custom solution quote.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does PTFE react to ammonia? Discover Its Superior Chemical Resistance

- What factors should be considered when choosing between PTFE lined and hard seal butterfly valves? Ensure Optimal Performance and Safety

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- How does PTFE behave in terms of chemical inertness? Unmatched Resistance for Demanding Applications

- How do PTFE-lined valves prevent leakage and contamination? Ensure Purity and Protect Equipment