At their core, PTFE-lined valves prevent leakage and contamination by creating a complete, chemically inert barrier. This Polytetrafluoroethylene (PTFE) lining isolates the fluid being transported from all metallic parts of the valve, which simultaneously protects the fluid from being contaminated and protects the valve from being corroded by the fluid.

The primary function of a PTFE-lined valve is not just to contain a fluid, but to maintain a strict separation. This dual protection—safeguarding the fluid's purity while defending the valve's structural integrity—is the reason it is a critical component in handling corrosive or high-purity media.

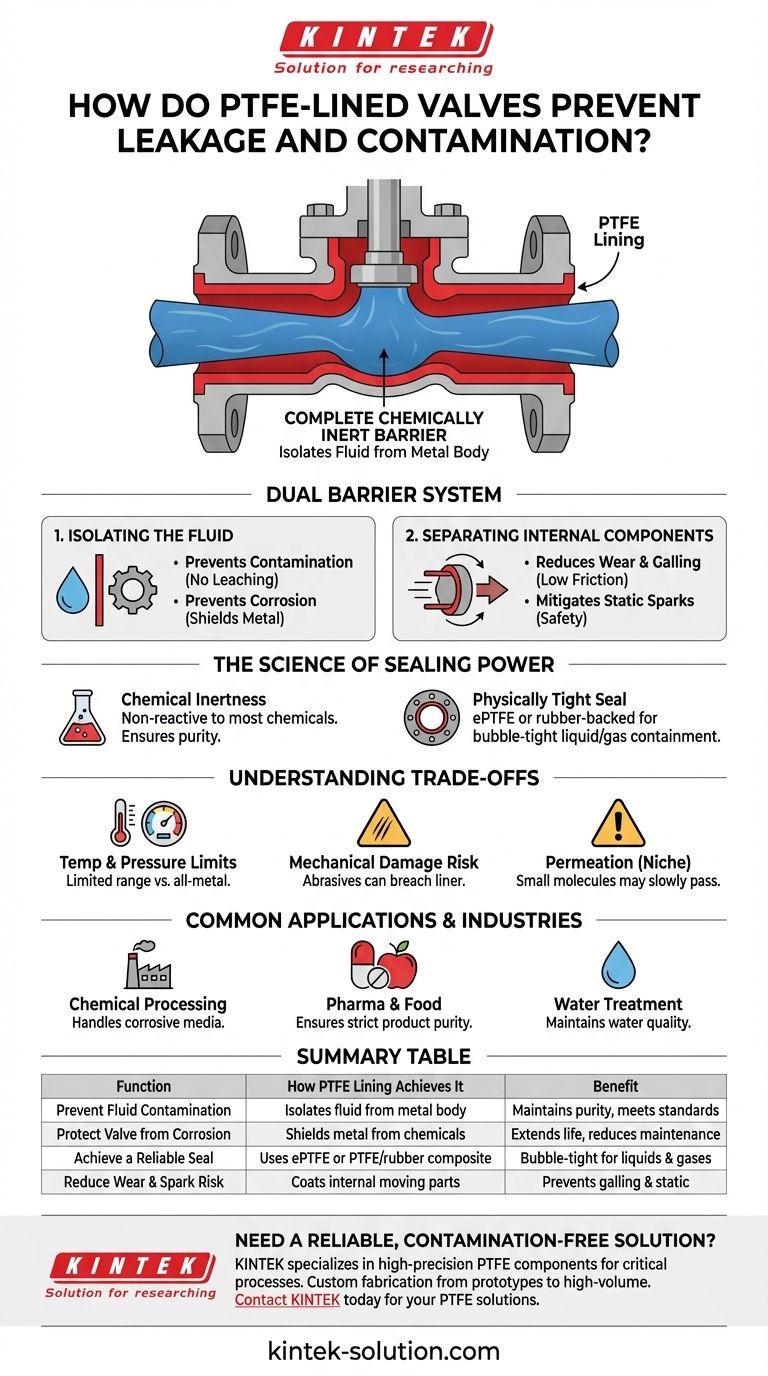

How PTFE Creates a Dual Barrier

The effectiveness of a PTFE-lined valve stems from its ability to act as two distinct barriers simultaneously. This protects both the internal and external integrity of the system.

Isolating the Fluid from the Valve Body

The most critical function of the PTFE liner is to ensure that the process fluid—whether it's an aggressive acid or a high-purity pharmaceutical compound—only ever touches the inert PTFE surface.

This isolation directly prevents contamination of the fluid, as there is no opportunity for the fluid to react with or leach metallic ions from the valve body.

It also prevents corrosion of the valve itself. The metal components are shielded from chemicals, dramatically extending the valve's service life in harsh environments.

Separating Internal Valve Components

In some designs, PTFE coatings are also used to eliminate contact between different moving metal parts within the valve assembly.

This prevents the gradual wear and galling that can occur from metal-on-metal friction. It also serves a key safety function by mitigating the risk of static electricity sparks, which can be an ignition source in volatile environments.

The Science Behind PTFE's Sealing Power

The material properties of PTFE are uniquely suited for creating a robust and reliable seal in demanding industrial applications.

The Role of Chemical Inertness

PTFE is one of the most non-reactive materials known. It is virtually immune to attack from the vast majority of industrial chemicals, acids, and bases.

This property is paramount in industries like pharmaceuticals and chemical processing, where even trace amounts of reactivity can compromise the final product's purity and safety.

Achieving a Physically Tight Seal

PTFE is not inherently elastic, but it is engineered into highly effective seals. For example, expanded PTFE (ePTFE) gaskets create a tight seal that effectively contains both liquids and gases.

In butterfly valves, a common design involves a flexible rubber seat that is lined with PTFE. This combines the flexibility and compression of rubber with the chemical resistance and non-stick qualities of the PTFE surface, resulting in a durable, bubble-tight seal.

Understanding the Trade-offs

While highly effective, PTFE-lined valves are not a universal solution. Understanding their limitations is key to proper application.

Temperature and Pressure Constraints

PTFE has a more limited operating temperature and pressure range compared to all-metal valves. High temperatures can cause the liner to soften or deform, while extreme pressures can challenge the integrity of the lining bond.

Susceptibility to Mechanical Damage

The PTFE liner is a barrier, and if that barrier is breached, its protective qualities are lost. Abrasive slurries or careless handling during installation can scratch or gouge the liner, creating a path for corrosion or contamination.

Permeation by Specific Media

While PTFE has extremely low permeability, very small molecules like certain gases (e.g., hydrogen, helium) can slowly permeate the liner over time, especially at higher temperatures. This is a niche concern but critical for certain high-purity or high-pressure gas applications.

Common Applications and Industries

The unique benefits of PTFE-lined valves make them indispensable in several key sectors.

Chemical and Petrochemical Processing

In these industries, valves must withstand highly corrosive substances. PTFE lining protects the valve's structural components from acids, bases, and other aggressive media, preventing costly equipment failure.

Pharmaceutical and Food Production

Here, the primary concern is product purity. PTFE's non-reactive and non-stick surface ensures that the process fluid is not contaminated in any way, meeting strict regulatory standards.

Water Treatment and High-Purity Systems

PTFE-lined valves prevent any unwanted chemicals from leaching into treated or purified water streams. This ensures the final water quality is maintained without introducing contaminants from the equipment itself.

Making the Right Choice for Your Application

Selecting the right valve requires matching its strengths to your primary operational goal.

- If your primary focus is preventing fluid contamination: PTFE's extreme chemical inertness is its greatest strength, ensuring your process media remains pure.

- If your primary focus is protecting equipment from corrosion: The liner acts as a complete shield, isolating the valve's structural metal from aggressive chemicals.

- If your primary focus is achieving a reliable, low-leakage seal: The combination of PTFE's properties with flexible seating materials provides a robust barrier against both liquids and gases.

Ultimately, selecting a PTFE-lined valve is an investment in both process purity and long-term asset integrity.

Summary Table:

| Function | How PTFE Lining Achieves It | Benefit |

|---|---|---|

| Prevent Fluid Contamination | Isolates fluid from metallic valve body | Maintains product purity, meets regulatory standards |

| Protect Valve from Corrosion | Shields metal components from aggressive chemicals | Extends service life, reduces maintenance costs |

| Achieve a Reliable Seal | Uses ePTFE or PTFE/rubber composite seats | Bubble-tight seal for liquids and gases |

| Reduce Wear & Spark Risk | Coats internal moving parts | Prevents galling and mitigates static electricity |

Need a reliable, contamination-free sealing solution for your critical processes?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom seals, liners, and labware. Our expertise ensures your valves and systems in the semiconductor, medical, laboratory, and industrial sectors operate with maximum integrity and purity.

We provide custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact KINTEK today to discuss how our PTFE solutions can protect your process and your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What temperature range can PTFE gaskets withstand in ball valve applications? From -200°C to 260°C

- What are the pressure and temperature limits for PEEK backup rings? Achieve Superior Sealing in Extreme Conditions

- What are the properties of Modified Polytetrafluoroethylene? Enhanced Performance for Demanding Applications

- How is PTFE packing utilized in the food industry? Ensuring Food Safety and Efficiency

- What are the steps for installing PTFE seals? A Guide to Leak-Free, Long-Lasting Performance

- What are the key benefits of Teflon bushes for industrial applications? Reduce Friction and Maintenance

- What is the function of PTFE lined check valves? Ensure Unidirectional Flow and Corrosion Resistance

- What precautions should be taken when specifying PTFE Lip Seals? Ensure Long-Term Reliability for Your Application