At its core, a piston seal is constructed from an elastic sealing ring. This component is precision-engineered to sit in a groove on a piston, where it forms a dynamic, tight barrier. Its primary function is to contain pressure and prevent the bypass of liquids or gases as the piston moves within a cylinder.

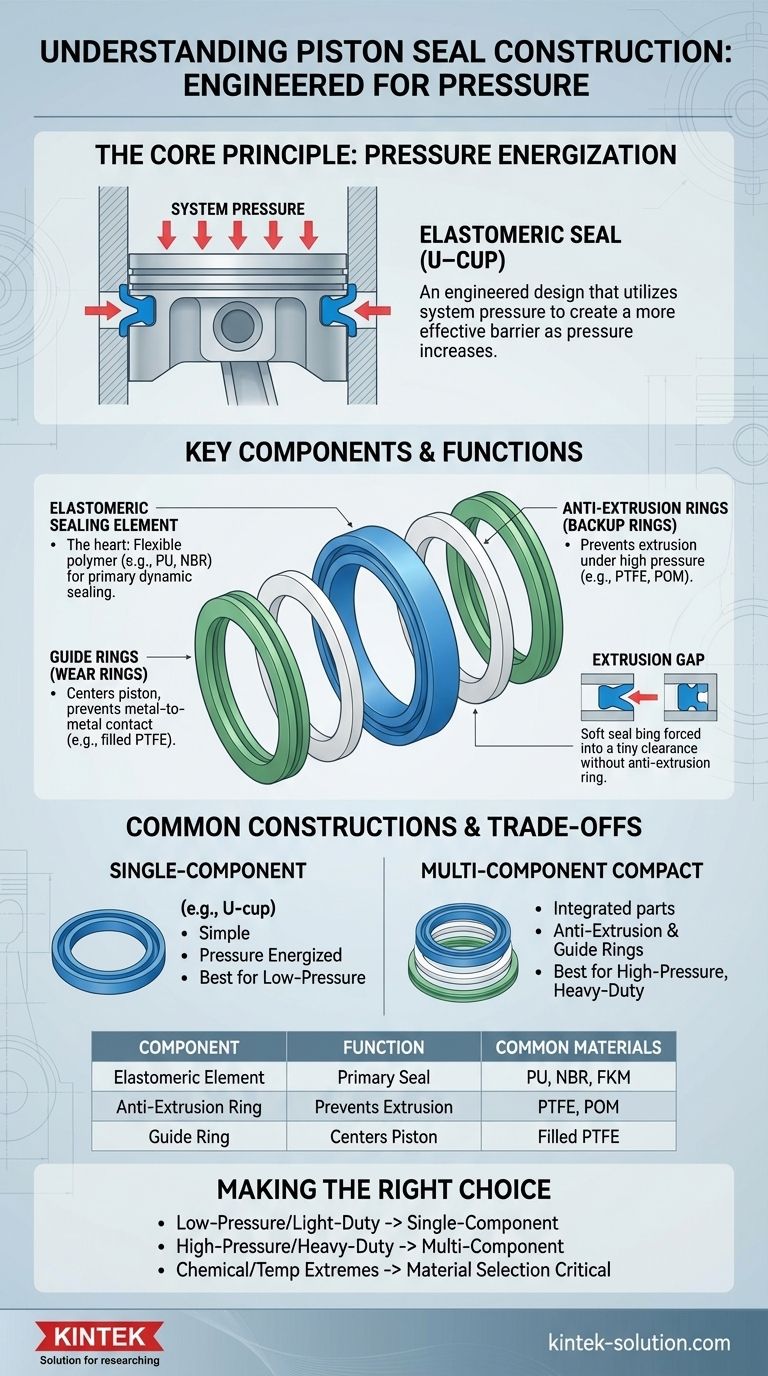

The critical insight is that a piston seal's construction is not just about a simple ring of material. It's an engineered design that intelligently uses the system's own pressure to energize the seal, creating a more effective barrier as pressure increases.

The Principle of Pressure Energization

A piston seal does not function like a simple plug. Its design is active, not passive. It leverages the pressure it is meant to contain to improve its own sealing capability.

The Elastomeric Sealing Element

The heart of the seal is the primary sealing element, almost always made from a flexible, resilient polymer or elastomer. The material choice is dictated by the application's fluid, temperature, and pressure.

Common materials include Polyurethane (PU) for its exceptional wear and extrusion resistance, or Nitrile rubber (NBR) for its excellent performance with mineral oils.

The Role of Anti-Extrusion Rings

Under high pressure, the soft elastomeric element can be forced into the tiny clearance gap between the piston and the cylinder wall. This phenomenon, called extrusion, quickly destroys the seal.

To prevent this, many piston seals are constructed with one or two anti-extrusion rings (also called backup rings). These are made of a harder, more rigid material like PTFE or POM and provide a robust backing for the softer sealing element.

The Function of Guide Rings

While technically separate, guide rings (or wear rings) are a crucial part of the overall piston head construction that enables the seal to function correctly.

These rings, often made of a low-friction plastic, prevent metal-to-metal contact between the piston and the cylinder bore. This ensures the piston remains perfectly centered, which protects the seal from uneven wear and catastrophic failure.

Common Piston Seal Constructions

Piston seals are constructed in various configurations, from simple single-piece designs to complex multi-component assemblies.

Single-Component Seals

The most common example is the U-cup. Its U-shaped cross-section is designed so that system pressure enters the "U" and pushes the inner and outer sealing lips firmly against the piston groove and the cylinder wall, respectively. This is a perfect illustration of pressure energization.

Multi-Component Compact Seals

For more demanding, high-pressure applications, a compact seal is used. This construction integrates multiple parts into a single, easy-to-install unit.

A typical compact seal consists of a central elastomeric sealing element, flanked by two anti-extrusion rings, and sometimes two outer guide rings, all housed together.

Understanding the Trade-offs

The construction of a piston seal is always a balance of competing factors. Choosing the right design requires understanding these compromises.

Single-Acting vs. Double-Acting

The physical construction must match the cylinder's function. A single-acting cylinder only requires a seal designed to hold pressure from one direction.

A double-acting cylinder, which performs work in both extension and retraction, needs a symmetrical seal construction capable of sealing pressure dynamically from either side.

Material vs. System Demands

There is no universal seal material. A seal constructed from Polyurethane offers incredible durability but may not be compatible with certain aggressive fluids or high temperatures, where a material like FKM (Viton) would be required despite its different physical properties.

Pressure vs. Extrusion Gap

The need for anti-extrusion rings in the seal's construction is directly related to two factors: the maximum system pressure and the size of the extrusion gap (the clearance between the piston and cylinder). Higher pressures or larger gaps make a multi-component construction with anti-extrusion rings mandatory.

Making the Right Choice for Your System

The ideal piston seal construction is the one that provides the longest service life for its specific operating conditions.

- If your primary focus is a low-pressure, light-duty application: A single-component U-cup construction often provides a reliable and cost-effective solution.

- If your primary focus is a high-pressure, heavy-duty industrial system: A multi-component compact seal with integrated anti-extrusion and guide rings is the standard for ensuring durability.

- If your primary focus is chemical compatibility or extreme temperatures: The material selection becomes the most critical aspect of the seal's construction, superseding the physical design.

Ultimately, understanding the construction of a piston seal is to understand how a simple ring can be engineered into a dynamic component that ensures the efficiency and reliability of the entire system.

Summary Table:

| Component | Primary Function | Common Materials |

|---|---|---|

| Elastomeric Sealing Element | Creates the primary dynamic seal by flexing against surfaces. | Polyurethane (PU), Nitrile Rubber (NBR), FKM (Viton) |

| Anti-Extrusion Ring (Backup Ring) | Prevents the soft seal from being forced into gaps under high pressure. | PTFE, POM (Acetal) |

| Guide Ring (Wear Ring) | Centers the piston, prevents metal-to-metal contact, and protects the seal. | Low-friction plastics (e.g., filled PTFE) |

Need a High-Performance Piston Seal?

Understanding the precise construction is the first step. The next is sourcing a seal engineered for your exact application's pressure, media, and temperature demands.

KINTEK specializes in manufacturing custom PTFE and polymer components, including critical seals and anti-extrusion rings. We serve the semiconductor, medical, laboratory, and industrial sectors with a focus on precision and durability.

Whether you need a simple U-cup or a complex multi-component compact seal, we provide custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your sealing requirements and ensure your system's reliability.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance