In short, anti-stick coatings dramatically simplify Polytetrafluoroethylene (PTFE) gasket maintenance by preventing the gasket from adhering to flange surfaces. This makes removal faster and cleaner, reduces the risk of damaging both the gasket and the metal flange, and ultimately improves the reliability and lifespan of the sealed joint.

The core challenge with PTFE gaskets is their tendency to stick to flange faces under high temperature and pressure, leading to difficult maintenance and potential equipment damage. Anti-stick coatings create a non-adherent barrier, transforming a time-consuming and risky task into a predictable and efficient process.

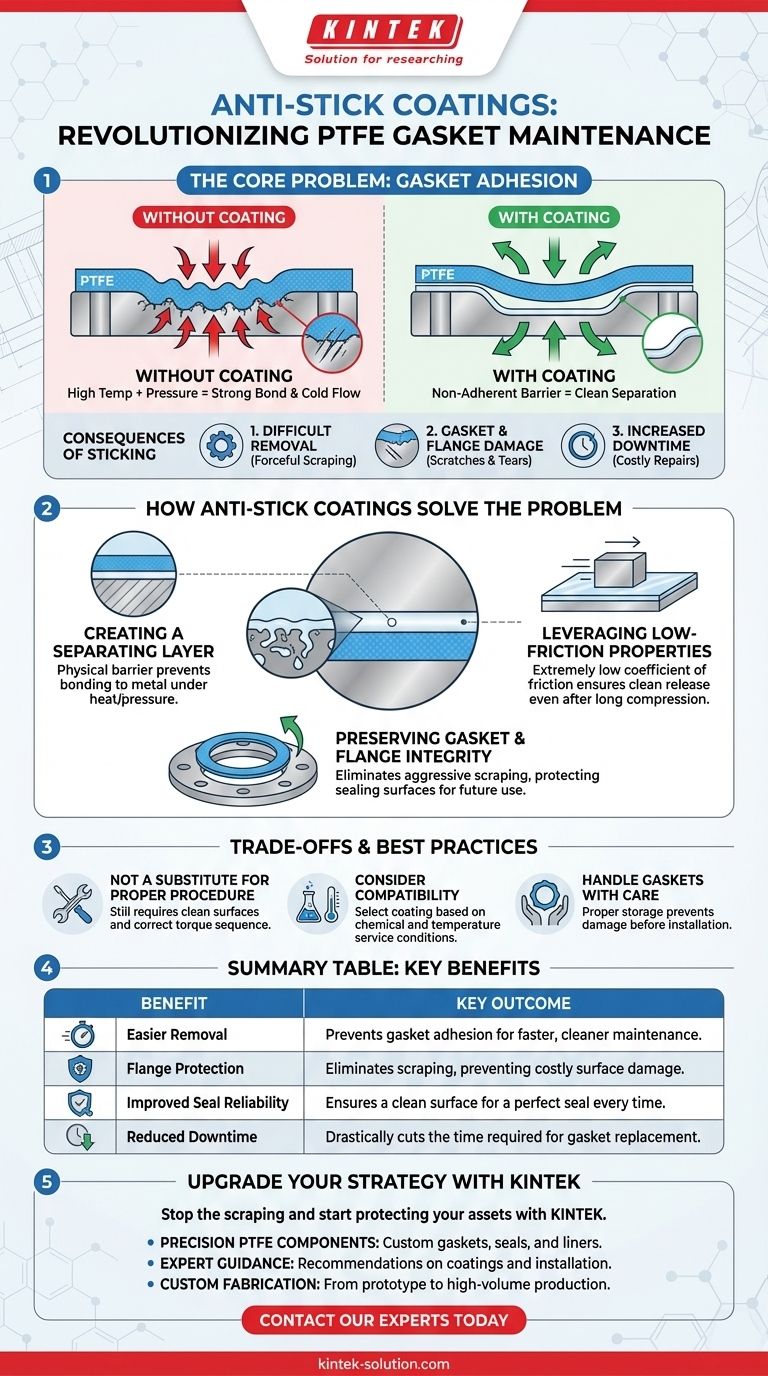

The Core Problem: Gasket Adhesion

When a PTFE gasket is installed and subjected to operational stress, it can become difficult to remove. Understanding why this happens is key to preventing it.

Why PTFE Gaskets Stick

Under the immense pressure of a bolted flange, the PTFE material can "cold flow" or extrude into the microscopic imperfections of the metal flange surface. When combined with high temperatures, this creates a powerful bond that effectively glues the gasket in place.

The Consequences of Sticking

A stuck gasket is more than an annoyance; it's a source of significant operational risk. The forceful scraping required to remove it can tear the gasket, leave behind hard-to-clean residue, and, most critically, gouge or scratch the precision-machined flange face.

Damaged flange surfaces can compromise the integrity of the next seal, leading to dangerous leaks, unplanned downtime, and costly flange resurfacing.

How Anti-Stick Coatings Solve the Problem

Anti-stick coatings provide a simple and effective solution by fundamentally changing the interaction between the gasket and the flange.

Creating a Separating Layer

The coating acts as a physical, non-adherent barrier. It fills the microscopic voids in the flange surface and presents a slick face to the gasket, preventing the material from bonding to the metal under heat and pressure.

Leveraging Low-Friction Properties

Coatings, particularly those based on PTFE, have an extremely low coefficient offriction. This inherent slipperiness ensures that even after being compressed for long periods, the gasket will release cleanly from the flange with minimal effort.

Preserving Gasket and Flange Integrity

By facilitating a clean release, the coating allows the old gasket to be removed intact. This eliminates the need for aggressive scraping, thereby protecting the delicate flange sealing surface from damage and ensuring a perfect surface for the next installation.

Understanding the Trade-offs and Best Practices

While highly effective, coatings are a tool that must be used correctly within a broader maintenance strategy.

Coatings Are Not a Substitute for Proper Procedure

An anti-stick coating cannot fix poor installation practices. You must still ensure the flange surfaces are clean, in good condition, and that the bolts are tightened to the correct torque specification using the proper sequence.

Consider Chemical and Temperature Compatibility

Always select a coating appropriate for the gasket material and the service conditions. For example, a silicone-based spray may not be suitable for the extreme temperatures or aggressive chemicals that a PTFE gasket can handle. Molybdenum disulfide is often preferred for very high-pressure applications.

Handle Gaskets with Care

Proper handling and storage of PTFE gaskets are still critical. A coating will not protect a gasket that has been creased, bent, or stored improperly before installation, as this damage will compromise its sealing ability.

Making the Right Choice for Your Goal

Integrate anti-stick coatings into your maintenance plan based on your primary objective.

- If your primary focus is reducing maintenance downtime: Coatings enable rapid and clean gasket removal, drastically cutting the time spent scraping and cleaning flange surfaces.

- If your primary focus is asset protection: Coatings are your best defense against flange face damage, preventing costly resurfacing and extending the life of your equipment.

- If your primary focus is improving seal reliability: By ensuring a clean, undamaged surface for every new gasket, coatings contribute directly to a more consistent and dependable seal.

By thoughtfully applying anti-stick coatings, you can significantly enhance the efficiency, safety, and reliability of your sealed joints.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Easier Removal | Prevents gasket adhesion for faster, cleaner maintenance. |

| Flange Protection | Eliminates scraping, preventing costly surface damage. |

| Improved Seal Reliability | Ensures a clean surface for a perfect seal every time. |

| Reduced Downtime | Drastically cuts the time required for gasket replacement. |

Upgrade your PTFE gasket maintenance strategy with KINTEK.

Are you facing costly downtime and equipment damage from stuck PTFE gaskets? Our expertise in high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors means we understand the critical need for reliable, easy-to-maintain seals.

We can provide:

- Precision PTFE Components: Custom-manufactured gaskets, seals, liners, and labware built for your exact application.

- Expert Guidance: Recommendations on the best anti-stick coatings and installation practices for your specific operating conditions.

- Custom Fabrication: From prototype to high-volume production, ensuring you get the perfect part for maximum performance and longevity.

Stop the scraping and start protecting your assets. Contact our experts today to discuss your PTFE sealing challenges and solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the disadvantages of using bronze as a filler in PTFE? Trade-offs in Chemical & Non-Stick Properties

- What are some common applications of filled PTFE? Enhance Performance in Demanding Industries

- What electrical properties do PTFE gaskets possess? Unmatched Insulation for High-Frequency & High-Voltage Applications

- What are the limitations of PTFE in terms of fabrication? Navigating Manufacturing Challenges

- Can Teflon bearings be customized for specific applications? Tailor PTFE Bearings for Your Unique Needs

- What are critical installation practices for PTFE O-rings? Avoid Leaks and Ensure a Perfect Seal

- In which industries are machined PTFE parts commonly used? Discover the Essential High-Performance Material

- Why is Teflon difficult to machine to tight tolerances? Overcome Material Instability