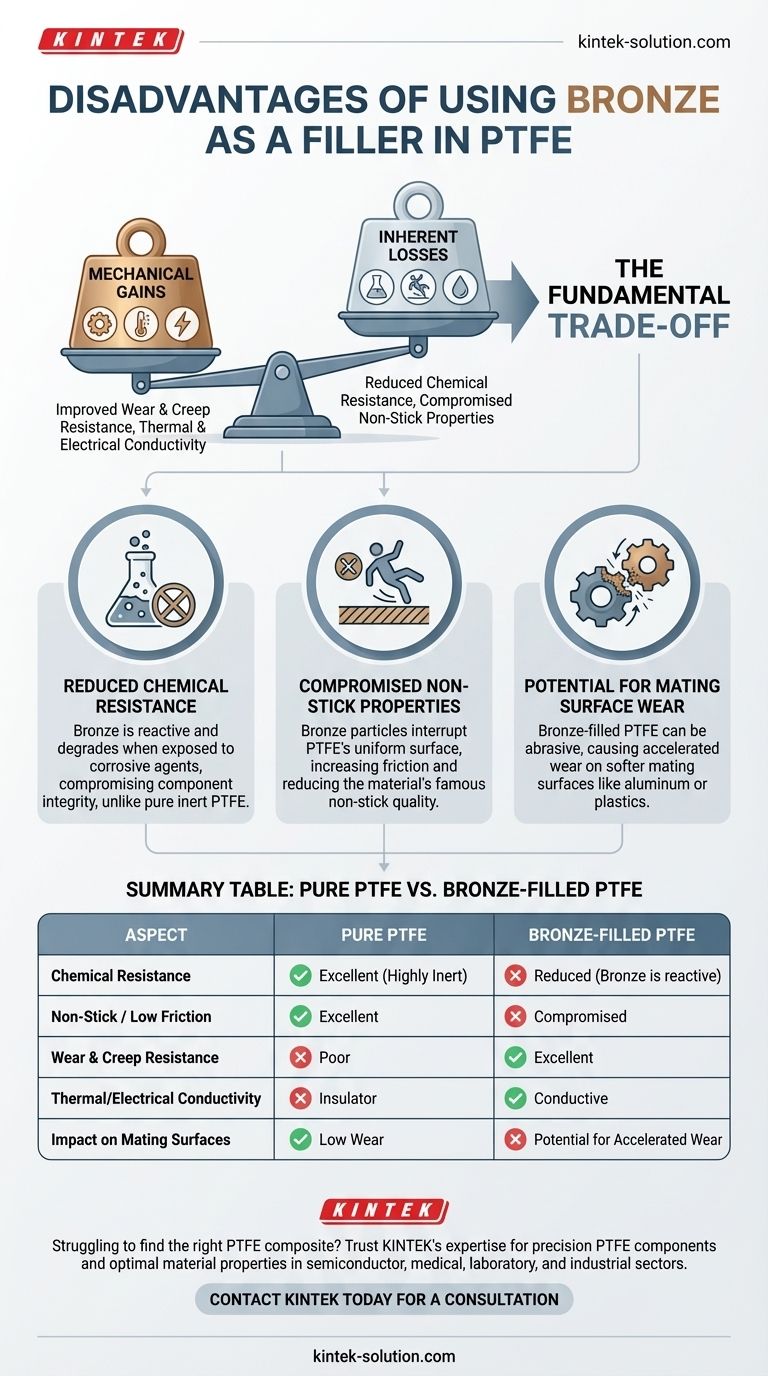

The primary disadvantages of using bronze as a filler in PTFE are a reduction in chemical resistance and a loss of its characteristic non-stick properties. While adding bronze significantly improves mechanical strength and conductivity, it does so by compromising some of the very features that make pure PTFE unique.

The core issue is a fundamental trade-off: you gain significant mechanical durability and thermal conductivity with bronze fillers, but you sacrifice the exceptional chemical inertness and low-friction surface that define pure Polytetrafluoroethylene (PTFE).

Why Add Fillers to PTFE in the First Place?

Before analyzing bronze specifically, it's crucial to understand why pure, unfilled PTFE often requires reinforcement. The material has remarkable properties but also significant inherent weaknesses.

The Limitations of Unfilled PTFE

Pure PTFE is exceptionally soft. This results in poor wear resistance when subjected to friction and a high degree of creep, which is the tendency for a solid material to deform permanently under a persistent load.

These limitations make unfilled PTFE unsuitable for many mechanical applications, especially those involving bearings or load-bearing parts where dimensional stability is critical.

The Goal of Reinforcement

Fillers are added to the PTFE matrix to enhance specific properties that the base polymer lacks. The choice of filler is a deliberate engineering decision based entirely on the demands of the final application.

The Key Disadvantages of Bronze-Filled PTFE

Adding bronze particles creates a powerful composite material, but these advantages come with distinct and important downsides that must be considered.

Reduced Chemical Resistance

One of PTFE's most valued characteristics is its extreme chemical inertness. It can resist nearly all industrial chemicals and solvents.

However, bronze is a metal alloy and does not share this property. When exposed to certain corrosive agents, the bronze particles can react and degrade, compromising the integrity of the entire component.

Compromised Non-Stick Properties

The exceptionally low coefficient of friction of PTFE gives it its famous non-stick, or low-friction, surface.

Introducing bronze particles into the matrix interrupts this uniform surface. This results in slightly higher friction and reduces the material's non-stick quality, which can be a critical failure in applications that rely on pure slip.

Potential for Mating Surface Wear

While bronze-filled PTFE is highly resistant to wear itself, it can be more abrasive to the surfaces it comes into contact with.

Softer mating surfaces, such as those made from aluminum or certain plastics, may experience accelerated wear when running against a harder, bronze-filled component compared to unfilled PTFE.

Understanding the Full Trade-off: The Advantages of Bronze

To make an informed decision, you must weigh the disadvantages against the significant performance gains that bronze provides.

Superior Wear and Creep Resistance

The primary reason to add bronze is to dramatically improve mechanical properties. Bronze-filled PTFE has excellent compressive strength and is far more resistant to wear and creep than its unfilled counterpart, making it ideal for high-load applications.

Enhanced Thermal and Electrical Conductivity

Pure PTFE is an excellent thermal and electrical insulator. Bronze, being a metal, is conductive.

Adding bronze filler allows the material to dissipate heat from high-friction contact points and prevent the buildup of static electricity, which is critical in certain operating environments.

Making the Right Choice for Your Application

The decision to use bronze-filled PTFE depends entirely on your primary performance requirements.

- If your primary focus is mechanical strength and wear resistance: Bronze-filled PTFE is an excellent choice for bearings, seals, and slide pads in high-load, high-speed applications.

- If your primary focus is chemical inertness: You should use unfilled PTFE or consider a more inert filler, such as glass, for applications involving aggressive chemicals.

- If your primary focus is thermal or electrical management: Bronze-filled PTFE is a strong candidate for dissipating heat or static charge where mechanical durability is also needed.

Ultimately, material selection is about choosing the right set of properties for the job at hand.

Summary Table:

| Aspect | Pure PTFE | Bronze-Filled PTFE |

|---|---|---|

| Chemical Resistance | Excellent (Highly Inert) | Reduced (Bronze is reactive) |

| Non-Stick / Low Friction | Excellent | Compromised |

| Wear & Creep Resistance | Poor | Excellent |

| Thermal/Electrical Conductivity | Insulator | Conductive |

| Impact on Mating Surfaces | Low Wear | Potential for Accelerated Wear |

Struggling to find the right PTFE composite for your application? The choice between pure PTFE and filled variants like bronze is critical for performance and longevity. At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the optimal material properties, whether you need prototypes or high-volume orders. Let our experts guide you to the perfect solution. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech