For demanding industrial applications, filled PTFE is used to create high-performance seals, bearings, bushings, and piston rings. These components are critical in industries like aerospace, chemical processing, and automotive, where standard PTFE would fail due to its softness and tendency to deform under load. Fillers like glass, carbon, and bronze are added to the base PTFE to dramatically improve its mechanical strength, wear resistance, and thermal stability.

The core purpose of adding fillers to PTFE is to overcome its inherent physical limitations. While virgin PTFE is exceptionally inert and low-friction, it is also soft and prone to wear; fillers transform it into a robust engineering material tailored for specific high-stress environments.

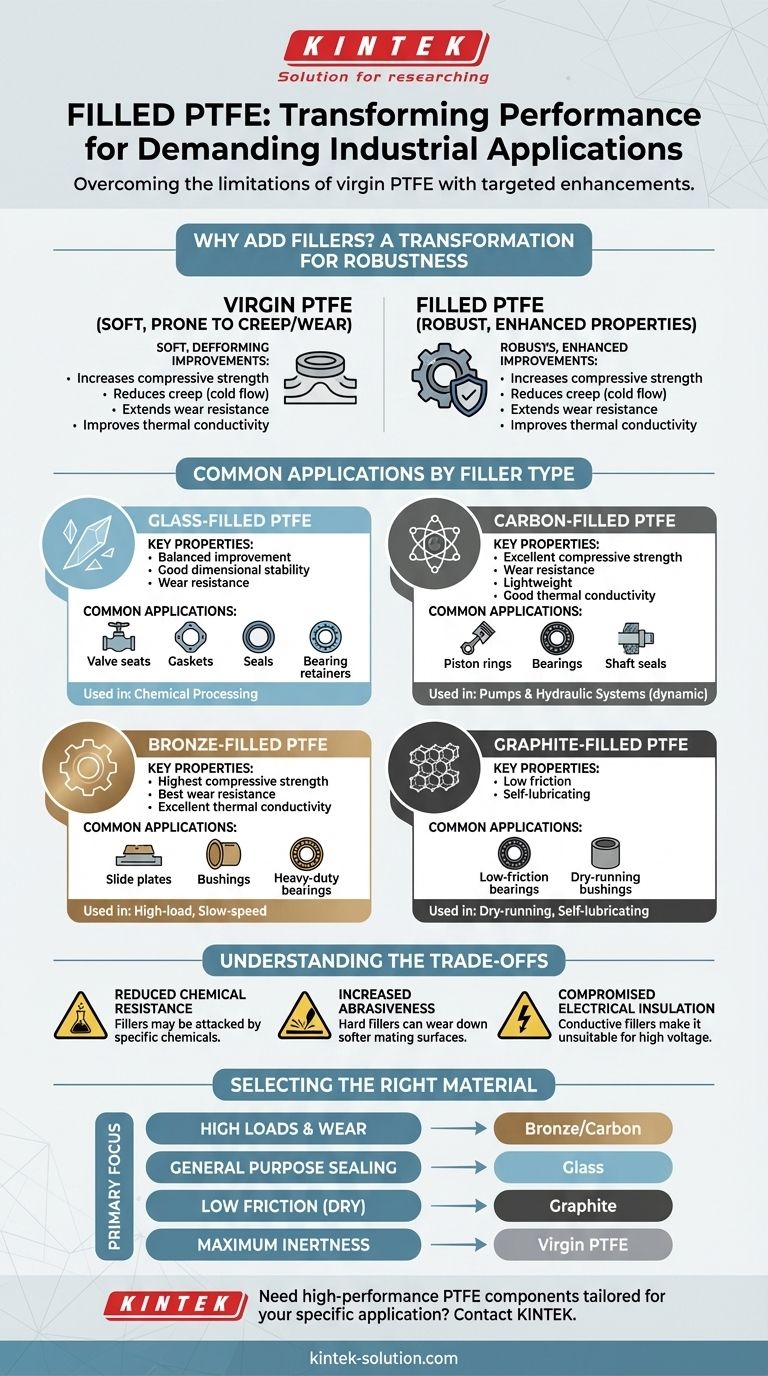

Why Add Fillers to PTFE?

To understand the applications of filled PTFE, you must first understand the limitations of unfilled, or "virgin," PTFE. While it has remarkable chemical resistance and a very low coefficient of friction, it has poor mechanical properties.

Overcoming Creep (Cold Flow)

Virgin PTFE is soft and will deform permanently under sustained pressure, a phenomenon known as creep or cold flow. Fillers act as a reinforcing matrix within the PTFE, significantly increasing its compressive strength and resistance to deformation under load.

Enhancing Wear Resistance

PTFE has poor abrasion resistance on its own. The addition of hard filler particles, such as glass or carbon, dramatically improves the material's ability to withstand friction and wear, extending the service life of components in dynamic applications.

Improving Thermal Properties

While PTFE has a wide operating temperature range, it is a poor thermal conductor. Fillers like bronze or graphite can increase thermal conductivity, allowing heat to dissipate from surfaces like bearings, which prevents thermal expansion and premature failure.

Common Applications by Filler Type

The choice of filler directly determines the material's ideal application. Different fillers provide a unique balance of mechanical, thermal, and chemical properties.

Glass-Filled PTFE

Glass is the most common filler. It provides a great all-around improvement in dimensional stability and wear resistance with only a minor impact on chemical and electrical properties.

Common applications include valve seats, gaskets, seals, and bearing retainers. It is often used in chemical processing equipment where both mechanical performance and chemical inertness are required.

Carbon-Filled PTFE

Carbon provides excellent compressive strength and wear resistance, especially when combined with graphite. It is lightweight and has good thermal conductivity and is suitable for contact with water and steam.

This makes it ideal for dynamic applications like piston rings, bearings, and shaft seals in pumps and hydraulic systems.

Bronze-Filled PTFE

Bronze fillers yield the highest compressive strength and wear resistance of all filled grades. This material also has excellent thermal conductivity, making it resistant to creep at high temperatures.

It is best suited for high-load, slow-speed applications such as slide plates, bushings, and heavy-duty bearings.

Graphite-Filled PTFE

Graphite is primarily added to reduce the coefficient of friction, creating a self-lubricating material. It is often combined with other fillers like carbon or glass.

Its main use is in low-friction bearings and bushings for applications that must run dry, without external lubrication.

Understanding the Trade-offs

Adding fillers to PTFE is not a universal upgrade. The improvements in mechanical properties come with specific compromises that are critical to consider.

Reduced Chemical Resistance

While the PTFE matrix remains inert, the fillers themselves can be attacked by certain chemicals. For example, glass fibers can be targeted by strong alkalis, and bronze is susceptible to corrosion from certain acids.

Increased Abrasiveness on Mating Surfaces

Hard fillers like glass can be abrasive to softer counter-surfaces, such as shafts made of stainless steel or aluminum. This requires careful material pairing to prevent premature wear on the entire assembly.

Compromised Electrical Insulation

Virgin PTFE is an excellent electrical insulator. However, common fillers like carbon, graphite, and bronze are conductive. This makes most filled PTFE grades unsuitable for high-voltage electrical applications.

Selecting the Right Filled PTFE for Your Application

Choosing the correct material depends entirely on the primary challenge you are trying to solve.

- If your primary focus is high loads and wear resistance: Bronze-filled or carbon-filled PTFE are the superior choices for structural integrity.

- If your primary focus is general-purpose sealing with improved durability: Glass-filled PTFE offers the most balanced property profile for gaskets and valve seats.

- If your primary focus is low-friction, self-lubricating performance: Graphite-filled PTFE is engineered specifically for bearings and slides that cannot be lubricated externally.

- If your primary focus is maximum chemical inertness or electrical insulation: Unfilled (virgin) PTFE remains the only suitable option.

By matching the filler's specific enhancements to your application's demands, you can leverage PTFE's unique benefits in environments far beyond its natural capabilities.

Summary Table:

| Filler Type | Key Properties | Common Applications |

|---|---|---|

| Glass | Good wear resistance, dimensional stability | Valve seats, gaskets, seals |

| Carbon | High compressive strength, good thermal conductivity | Piston rings, bearings, shaft seals |

| Bronze | Highest compressive strength, excellent thermal conductivity | Slide plates, bushings, heavy-duty bearings |

| Graphite | Low friction, self-lubricating | Low-friction bearings, dry-running bushings |

Need high-performance PTFE components tailored for your specific application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require custom prototypes or high-volume production, our expertise in material selection and fabrication ensures your components deliver optimal performance, durability, and reliability.

Contact us today to discuss your project requirements and let our team provide a solution that meets your exact needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection