Yes, Teflon™ (PTFE) bearings can be extensively customized. Engineering teams can tailor nearly every aspect of a PTFE bearing, from its core material composition to its physical shape and size, to meet the precise demands of a specific application. This adaptability makes it a go-to solution for non-standard engineering challenges.

Customizing a Teflon™ bearing is not just about changing its dimensions. It’s about fundamentally altering the material's properties and geometry to solve specific operational problems, whether that involves extreme temperatures, corrosive chemicals, or irregularly shaped components.

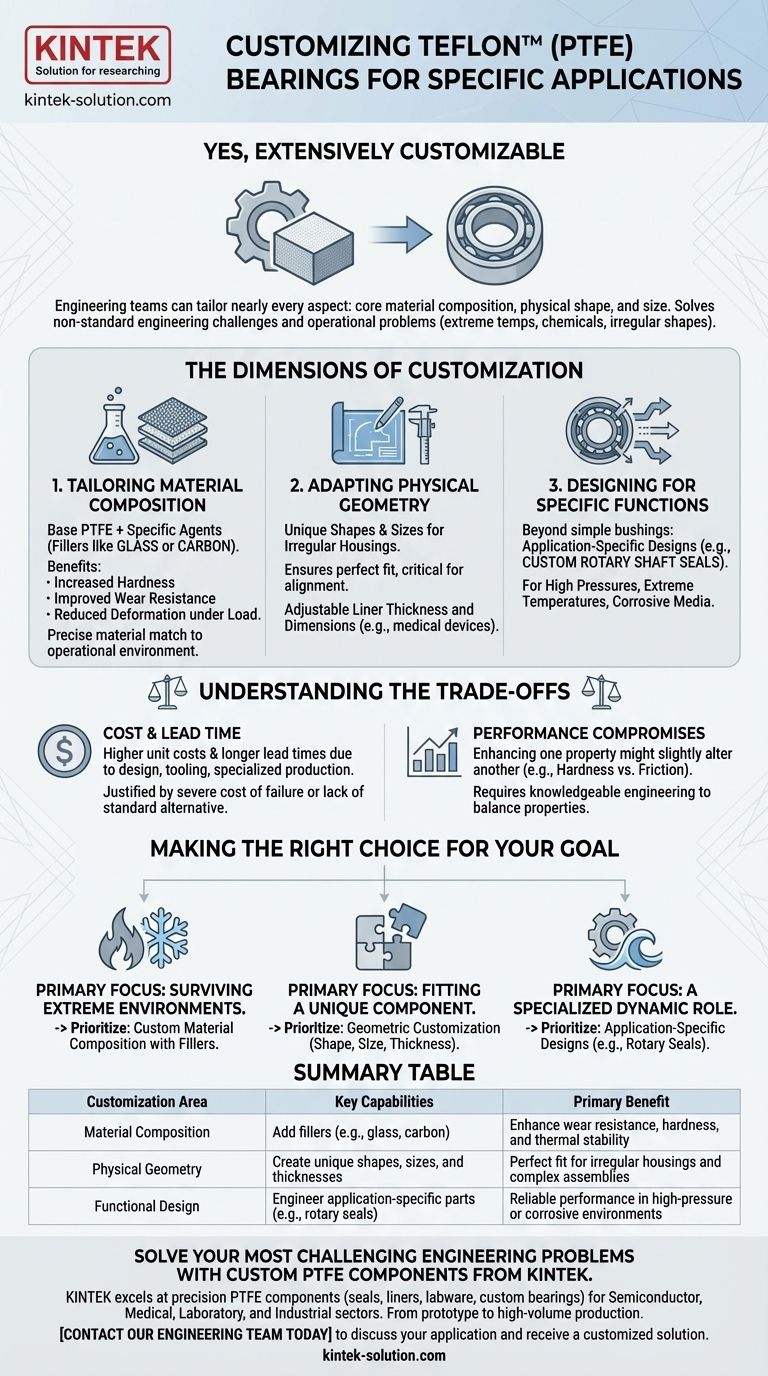

The Dimensions of Customization

True customization of a PTFE bearing extends across three key areas: its material makeup, its physical form, and its functional design.

Tailoring Material Composition

The base PTFE material is a starting point. Its properties can be significantly enhanced by adding fillers to create a composite material.

Manufacturers blend PTFE with specific agents to target performance weaknesses or enhance strengths. Common fillers like glass or carbon can be added to increase hardness, improve wear resistance, and reduce deformation under load.

This process allows the bearing's material characteristics to be precisely matched to the operational environment.

Adapting Physical Geometry

Off-the-shelf bearings assume standard housing dimensions, which is not always the case in specialized machinery.

Customization allows for the manufacturing of bearings in unique shapes and sizes to fit into irregularly shaped housings. This ensures a perfect fit, which is critical for maintaining alignment and performance in complex assemblies.

Furthermore, aspects like liner thickness and specific dimensions can be adjusted, a common requirement in sensitive applications like medical devices.

Designing for Specific Functions

Some applications require more than just a simple bushing. They need a component designed for a specific dynamic role.

A prime example is custom rotary shaft seals. These are designed for demanding situations involving high pressures, extreme temperatures, or corrosive media where a standard seal would fail.

By tailoring the seal's design and material, it can provide reliable performance in environments that are otherwise unserviceable.

Understanding the Trade-offs

While customization offers significant advantages, it's essential to approach it with a clear understanding of the associated trade-offs.

Cost and Lead Time

Custom solutions inherently involve design, tooling, and specialized production runs. This results in higher unit costs and longer lead times compared to standard, off-the-shelf components.

This investment is typically justified by the severe cost of failure or the lack of any viable standard alternative.

Performance Compromises

Enhancing one material property with a filler can sometimes slightly alter another. For example, adding glass fibers to increase hardness might minimally increase the coefficient of friction compared to pure PTFE.

A knowledgeable engineering partner is crucial for balancing these properties to achieve the best overall performance for your specific application.

Making the Right Choice for Your Goal

To determine the best path forward, consider your primary engineering challenge.

- If your primary focus is surviving extreme environments: Prioritize customizing the material composition with fillers suited for high temperatures, pressures, or chemical exposure.

- If your primary focus is fitting a unique component: Concentrate on the geometric customization of the bearing's shape, size, and thickness to match your housing.

- If your primary focus is a specialized dynamic role: Explore application-specific designs, such as custom rotary seals, that are engineered for your exact operational conditions.

Ultimately, a custom Teflon™ bearing is a powerful engineering tool for solving problems that standard components simply cannot address.

Summary Table:

| Customization Area | Key Capabilities | Primary Benefit |

|---|---|---|

| Material Composition | Add fillers (e.g., glass, carbon) | Enhance wear resistance, hardness, and thermal stability |

| Physical Geometry | Create unique shapes, sizes, and thicknesses | Perfect fit for irregular housings and complex assemblies |

| Functional Design | Engineer application-specific parts (e.g., rotary seals) | Reliable performance in high-pressure or corrosive environments |

Solve your most challenging engineering problems with custom PTFE components from KINTEK.

Standard bearings often fall short in extreme or specialized applications. KINTEK excels at manufacturing precision PTFE components—including seals, liners, labware, and custom bearings—for the semiconductor, medical, laboratory, and industrial sectors. We work with you from prototype to high-volume production to deliver a solution tailored to your exact requirements for temperature, chemical resistance, and unique geometry.

Contact our engineering team today to discuss your specific application and receive a customized solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining