In the chemical processing industry, Teflon rods are a critical stock material used to machine custom components that can survive direct, prolonged contact with highly corrosive chemicals. These components primarily include durable seals, gaskets, valve seats, and linings for tanks and pipes, where material failure is not an option.

The core value of Teflon in chemical processing isn't just its non-stick quality; it's the material's profound chemical inertness. This property allows engineers to build systems that contain and control aggressive substances without the risk of corrosion, equipment failure, or process contamination.

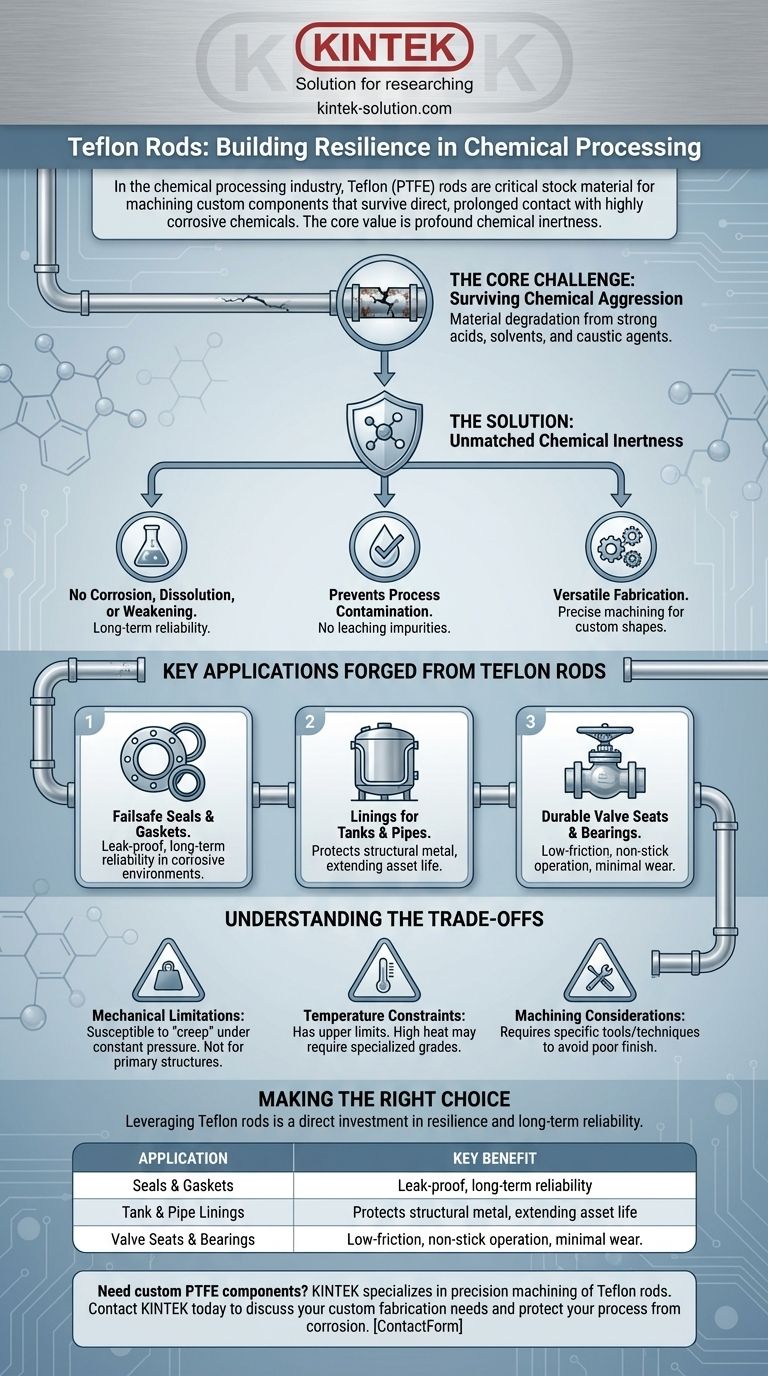

The Core Challenge: Surviving Chemical Aggression

The fundamental problem in any chemical plant is material degradation. Most metals, plastics, and elastomers will quickly break down when exposed to the strong acids, solvents, and caustic agents used in processing. Teflon provides a definitive solution.

Unmatched Chemical Inertness

Teflon, or Polytetrafluoroethylene (PTFE), is one of the most chemically resistant materials known. It is virtually immune to attack from acids, alkalis, and organic solvents.

This inertness ensures that components made from Teflon rods do not corrode, dissolve, or weaken over time, providing exceptional long-term reliability.

Preventing Process Contamination

Because Teflon does not react with the chemicals it contains, it does not leach impurities into the process stream. This is critical for industries like pharmaceuticals or specialty chemicals where product purity is paramount.

Versatility in Fabrication

Teflon rods serve as a versatile raw material. They can be precisely machined into a wide variety of custom shapes and sizes to fit specific equipment, making them ideal for creating bespoke parts for reactors, pumps, and valves.

Key Applications Forged from Teflon Rods

The unique properties of Teflon make it the material of choice for several critical applications where both chemical resistance and physical durability are required.

Failsafe Seals and Gaskets

The ability of Teflon to form a tight, leak-proof seal is essential for safety and operational efficiency. Gaskets and seals machined from Teflon rods prevent hazardous leaks and maintain pressure within vessels and pipes.

These components remain functional and do not become brittle or degrade, even after years of exposure to harsh chemicals.

Linings for Tanks and Pipes

To protect large, expensive steel tanks and piping systems from corrosion, they are often lined with Teflon. This lining acts as a barrier, shielding the structural metal from the aggressive contents.

Using Teflon in this way extends the life of critical infrastructure and prevents catastrophic failures.

Durable Valve Seats, Bearings, and Bushings

In components with moving parts, such as valves, Teflon’s low coefficient of friction is a major advantage. It ensures smooth, non-stick operation.

Valve seats, bearings, and bushings made from Teflon resist abrasion and wear, even in environments with high loads or constant motion. This drastically reduces the need for maintenance and prevents equipment seizure.

Understanding the Trade-offs

While incredibly effective, Teflon is not a universal solution. An expert understands its limitations and when to specify it.

Mechanical Limitations

Teflon is not as rigid or strong as metal. It is susceptible to "creep," or slow deformation, under constant high pressure. For this reason, it is typically used as a component or lining rather than for primary structural purposes.

Temperature Constraints

Although Teflon has a wide operating temperature range, it has distinct upper limits. In extremely high-temperature applications, other materials or specialized filled-grade versions of PTFE may be required.

Machining Considerations

Machining Teflon requires specific tools and techniques. Its relative softness compared to metals means that improper handling can result in poor surface finishes or dimensional inaccuracies, compromising the performance of the final part.

Making the Right Choice for Your Application

Selecting Teflon is a strategic engineering decision based on a specific operational need.

- If your primary focus is preventing leaks: Teflon rods are the ideal source material for machining custom gaskets and seals that remain inert and effective against aggressive chemicals.

- If your primary focus is protecting equipment integrity: Use Teflon for lining tanks and pipes to shield structural metals from corrosion, dramatically extending asset life and preventing failures.

- If your primary focus is reliable mechanical operation: Fabricate valve seats, bearings, and bushings from Teflon to ensure low-friction, non-stick performance that minimizes wear and reduces maintenance cycles.

Ultimately, leveraging Teflon rods is a direct investment in the resilience and long-term reliability of your chemical processing operations.

Summary Table:

| Application | Key Benefit |

|---|---|

| Seals & Gaskets | Leak-proof, long-term reliability in corrosive environments. |

| Tank & Pipe Linings | Protects structural metal from chemical attack, extending asset life. |

| Valve Seats & Bearings | Low-friction, non-stick operation with minimal wear and maintenance. |

Need custom PTFE components that guarantee chemical resistance and reliability?

KINTEK specializes in precision machining of Teflon rods into durable seals, liners, labware, and valve components for the semiconductor, medical, laboratory, and industrial sectors. We ensure your parts are fabricated to the highest standards, from prototypes to high-volume production.

Contact KINTEK today to discuss your custom fabrication needs and protect your process from corrosion.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE's pressure resistance compare to other materials? Unmatched Performance for Demanding Systems

- What support is available for selecting the right PTFE valve design and size? Get Expert Guidance for Your Application

- What are the two primary types of PTFE used in slide bearings and their respective applications? Choose the Right Grade for Your Load and Environment

- What is the difference between single-acting and double-acting piston seals? Choose the Right Seal for Your Hydraulic System

- How do additives and fillers specialize PTFE-based PCB materials? Tailor High-Frequency Circuit Performance

- What is the main difference between bronze and PTFE bushings? Choose the Right Bushing for Your Application

- Why are Metal-Polymer Bronze Backed PTFE Plain Bearings considered versatile? Unlock Maintenance-Free, High-Performance Solutions

- What should be considered when choosing a manufacturer for PTFE-lined bearings? Ensure Long-Term Reliability and Performance