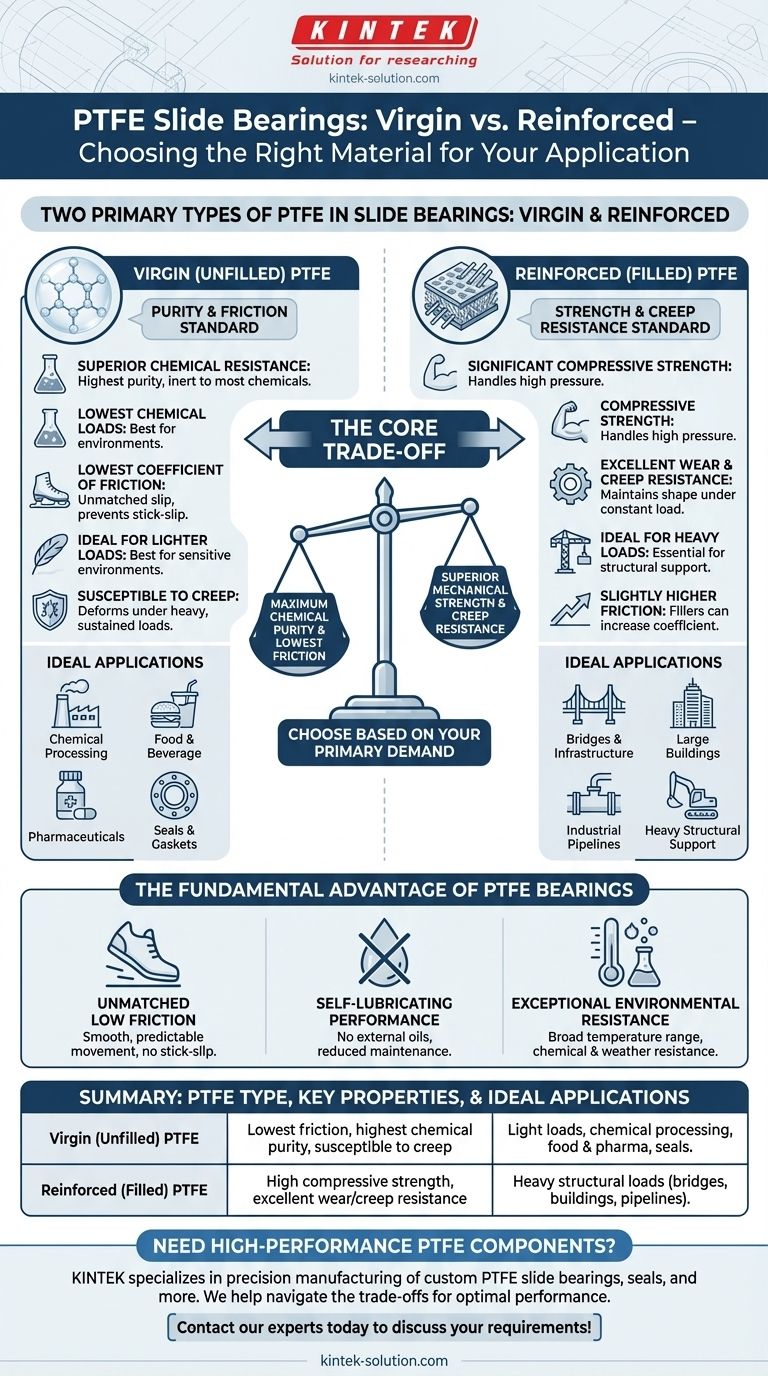

The two primary types of PTFE used in slide bearings are Virgin (unfilled) PTFE and Reinforced (filled) PTFE. Virgin PTFE is selected for its superior chemical resistance and the lowest coefficient of friction, making it ideal for lighter loads and sensitive environments. Reinforced PTFE contains fillers that significantly increase its compressive strength and resistance to wear and creep, making it the standard for heavy structural applications.

The core decision between Virgin and Reinforced PTFE is a direct trade-off. You must choose between the maximum chemical purity and lowest friction of Virgin PTFE for lighter loads, or the superior mechanical strength and creep resistance of Reinforced PTFE required for heavy loads.

The Fundamental Advantage of PTFE Bearings

Polytetrafluoroethylene (PTFE) is a high-performance polymer prized for its unique combination of properties, making it an exceptional material for bearing applications that operate under high loads and low speeds.

Unmatched Low Friction

PTFE possesses one of the lowest coefficients of friction of any solid material. This inherent slipperiness is critical for preventing stick-slip action, ensuring smooth, predictable movement as a bearing transitions from a static to a dynamic state.

Self-Lubricating Performance

The material is self-lubricating, eliminating the need for external oils or greases. This reduces maintenance requirements and makes PTFE ideal for applications where contamination is a concern or access is difficult.

Exceptional Environmental Resistance

PTFE exhibits remarkable resistance to a wide range of chemicals and is unaffected by weathering. It also maintains its structural integrity across a vast temperature range, providing excellent thermal insulation and stability in demanding conditions.

Differentiating the Two Primary PTFE Grades

While all PTFE bearings share these core advantages, the choice between virgin and reinforced grades is determined entirely by the application's specific mechanical demands.

Virgin PTFE: The Purity and Friction Standard

Virgin PTFE is pure, unfilled polytetrafluoroethylene. It offers the absolute best performance in terms of chemical inertness and low friction.

This makes it the material of choice in industries like chemical processing, food and beverage, and pharmaceuticals, where preventing contamination is non-negotiable. It is also used for seals, gaskets, and other non-structural components.

Reinforced PTFE: The Strength Standard

Reinforced PTFE is a composite material where fillers like glass fiber, carbon, or bronze are added to the PTFE base. These fillers dramatically improve its mechanical properties.

The primary benefit is a significant increase in compressive strength and resistance to creep—the tendency of a material to deform under constant load. This makes reinforced PTFE essential for heavy structural applications like bridges, large buildings, and industrial pipelines.

Understanding the Trade-offs

Selecting the right PTFE grade requires acknowledging the compromises inherent in each material. These trade-offs are central to proper engineering design.

The Cost of Reinforcement

While fillers add crucial strength, they can slightly increase the coefficient of friction compared to virgin PTFE. The specific filler used can also alter the material's chemical resistance, making it less suitable for certain corrosive environments.

The Limits of Virgin PTFE

Virgin PTFE's primary limitation is its susceptibility to creep under heavy, sustained loads. For any application involving significant structural weight, such as supporting a building span or a heavy pipe, virgin PTFE is not a suitable choice for the primary bearing surface.

Optimal Operating Conditions

Both types of PTFE slide bearings perform best under conditions of high load and low speed. These conditions leverage their self-lubricating properties most effectively, ensuring a durable and reliable service life.

Making the Right Choice for Your Application

Your final decision should be guided by the single most critical demand of your project.

- If your primary focus is supporting heavy structural loads: Reinforced PTFE is the only appropriate choice due to its superior strength and creep resistance.

- If your primary focus is maximum chemical inertness or food/pharma safety: Virgin PTFE is the required standard for its purity.

- If your primary focus is achieving the absolute lowest friction for lighter loads: Virgin PTFE provides the best performance.

By aligning the material's properties with your application's key requirements, you ensure optimal performance and long-term reliability.

Summary Table:

| PTFE Type | Key Properties | Ideal Applications |

|---|---|---|

| Virgin (Unfilled) PTFE | Lowest friction, highest chemical purity, susceptible to creep | Light loads, chemical processing, food & pharma, seals |

| Reinforced (Filled) PTFE | High compressive strength, excellent wear/creep resistance | Heavy structural loads (bridges, buildings, pipelines) |

Need High-Performance PTFE Components for Your Project?

Choosing the right PTFE grade is critical for bearing performance and longevity. KINTEK specializes in the precision manufacturing of PTFE components—including custom slide bearings, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We help you navigate the trade-offs between Virgin and Reinforced PTFE to ensure optimal performance for your specific application, from prototypes to high-volume production.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications