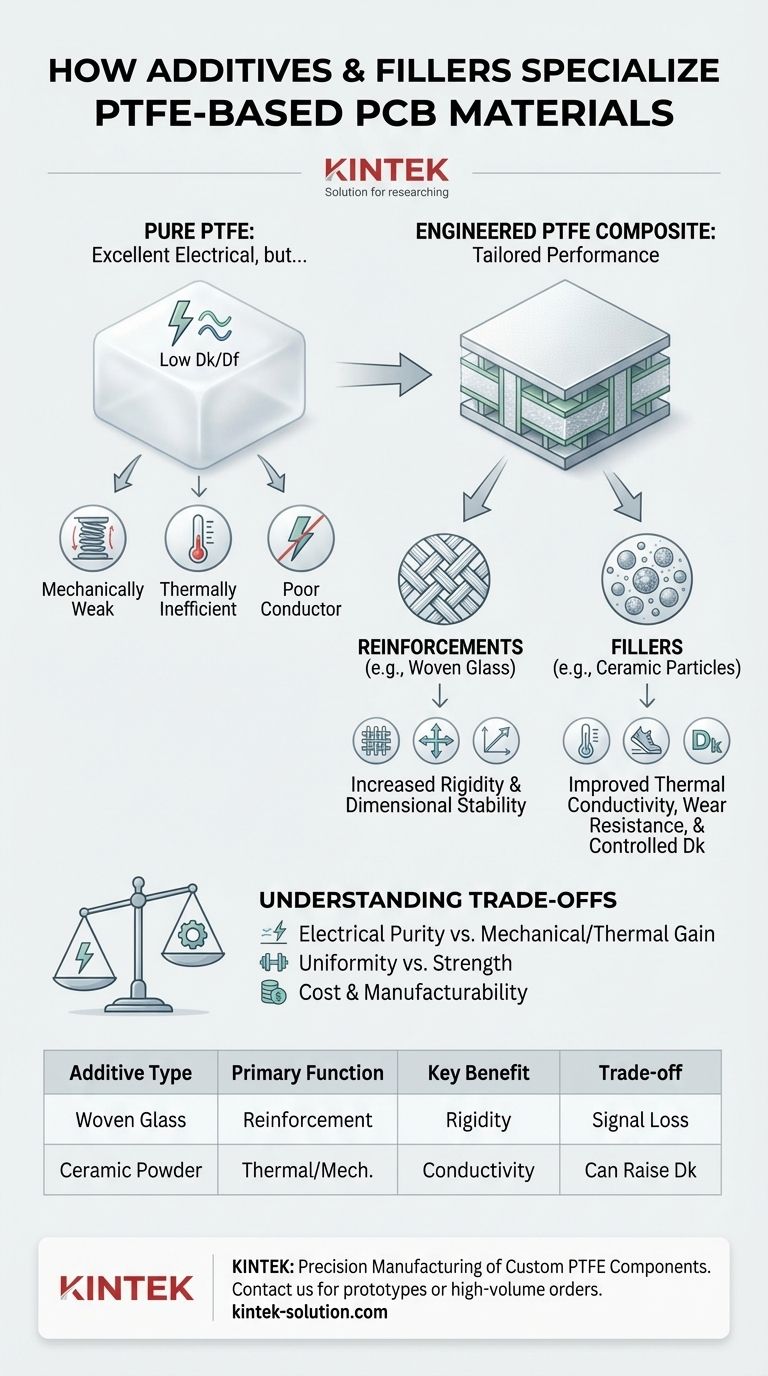

In essence, additives and fillers are used to overcome the inherent limitations of pure Polytetrafluoroethylene (PTFE). While pure PTFE offers exceptional electrical properties for high-frequency circuits, it is mechanically soft and thermally inefficient. By embedding specific additives and fillers into the PTFE matrix, manufacturers can engineer specialized laminates with enhanced mechanical, thermal, and electrical behaviors tailored to demanding applications.

The core purpose of adding fillers to PTFE is to transform it from a superior but physically soft insulator into a robust, high-performance circuit material. These additives allow engineers to customize a PTFE composite for specific targets, such as improved rigidity or heat dissipation, often without compromising its fundamental electrical advantages.

The Challenge with Pure PTFE

To understand the role of additives, we must first appreciate the profile of pure PTFE as a raw material. It possesses a valuable combination of properties but also significant drawbacks for printed circuit board (PCB) fabrication.

Exceptional Electrical Insulator

Pure PTFE has a very low and stable dielectric constant (Dk) and an extremely low dissipation factor (Df). This makes it an almost ideal insulator for high-frequency signals, minimizing signal loss and distortion, which is critical for microwave and millimeter-wave applications.

Inherent Mechanical Weakness

The primary drawback of PTFE is its softness. It is a highly flexible material that can easily deform under pressure, high temperatures, or the mechanical stress of an assembled component. This can lead to issues with dimensional stability and reliability in a finished PCB.

Poor Thermal Conductivity

PTFE is also a thermal insulator. It does not effectively conduct heat away from active components like power amplifiers. This can lead to hotspots on the PCB, reducing the performance and lifespan of the electronics.

How Additives Engineer a Solution

Additives are blended into the PTFE matrix to create a composite material that systematically addresses these weaknesses. They are generally categorized into two main types: reinforcements and fillers.

Reinforcements: Building a Structural Backbone

Reinforcements are added almost exclusively to improve the mechanical properties of the material. Their primary job is to provide rigidity and dimensional stability.

The most common reinforcement is woven glass or random glass microfibers. These elements create an internal skeleton within the PTFE, dramatically increasing its stiffness and reducing its tendency to deform under thermal or mechanical stress.

Fillers: The Multi-Purpose Modifier

Fillers are microscopic particles that can modify a much wider range of properties, affecting the mechanical, thermal, and even electrical behavior of the composite.

A common and highly effective filler is ceramic. Adding ceramic powder to the PTFE matrix improves wear resistance, reduces creep, and, most importantly, significantly increases the material's thermal conductivity, helping to dissipate heat.

Fillers can also be used to intentionally raise the dielectric constant (Dk) of the material in a highly controlled manner, which can be beneficial for certain circuit designs requiring miniaturization.

Understanding the Trade-offs

Selecting a filled PTFE material is an exercise in balancing competing requirements. Every additive that solves one problem introduces a new consideration.

The Impact on Electrical Purity

Adding any material, whether glass or ceramic, to pure PTFE will alter its pristine electrical properties. Reinforcements and fillers can slightly increase the dissipation factor (signal loss) of the final composite. The goal is to gain the needed physical properties with minimal electrical compromise.

Mechanical Stability vs. Uniformity

Woven glass provides excellent rigidity but introduces a non-uniformity to the material. The Dk can vary slightly depending on the orientation relative to the weave pattern. Random microfibers or spherical fillers can offer more isotropic (uniform in all directions) electrical properties at the cost of some structural strength.

Cost and Manufacturability

Highly specialized fillers and complex composite structures invariably increase the cost of the raw laminate. They can also introduce challenges during the PCB fabrication process, requiring specialized drilling and handling techniques compared to standard epoxy-glass (FR-4) materials.

Making the Right Choice for Your Application

The key is to match the material's engineered properties to the primary challenge of your design.

- If your primary focus is mechanical stability and rigidity: Choose a PTFE composite with a woven glass reinforcement to prevent warping and ensure dimensional control.

- If your primary focus is thermal management for high-power components: Select a material with ceramic fillers designed to provide high thermal conductivity.

- If your primary focus is the absolute purest electrical performance: A PTFE laminate with minimal filler content is ideal, but you must design your assembly to accommodate its mechanical softness.

By understanding how these additives and fillers specialize the material, you can select a PTFE-based laminate engineered precisely for the demands of your high-performance application.

Summary Table:

| Additive/Filler Type | Primary Function | Key Benefits | Common Trade-offs |

|---|---|---|---|

| Woven Glass | Mechanical Reinforcement | Increases rigidity, dimensional stability | Slight increase in signal loss, anisotropic Dk |

| Ceramic Powder | Thermal & Mechanical Filler | Improves thermal conductivity, wear resistance | Can raise Dk, may increase cost |

| Random Glass Microfibers | Isotropic Reinforcement | Provides uniform mechanical & electrical properties | Lower structural strength vs. woven glass |

Need a PTFE Component Engineered for Your Specific Application?

At KINTEK, we specialize in the precision manufacturing of custom PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in material science ensures your PTFE-based solutions deliver optimal mechanical stability, thermal management, and electrical performance.

Contact us today to discuss how we can customize PTFE materials for your high-performance requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs