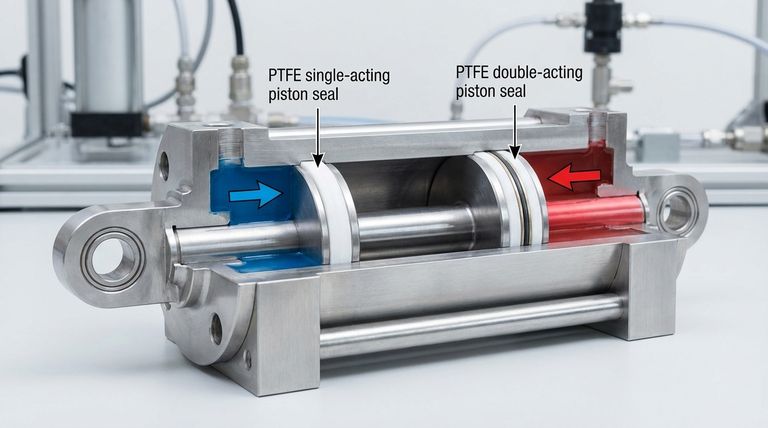

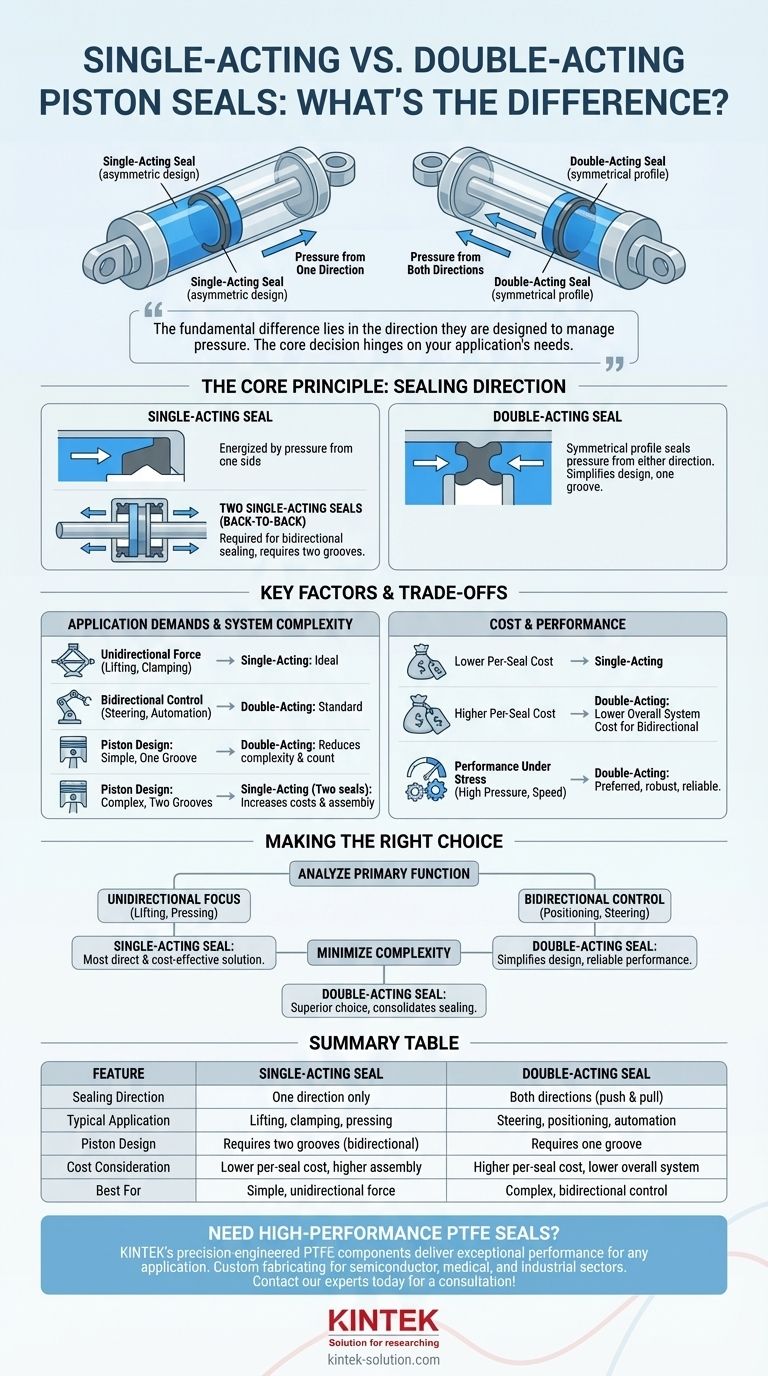

The fundamental difference between single-acting and double-acting piston seals lies in the direction they are designed to manage pressure. A single-acting seal is engineered to seal pressure from one specific direction, while a double-acting seal is built to handle pressure from both directions.

The core decision hinges on your application's needs. Single-acting seals offer a simple, cost-effective solution for unidirectional force, whereas double-acting seals provide a robust, all-in-one component for systems requiring bidirectional control.

The Core Principle: Sealing Direction

The function of a piston seal is to prevent fluid or air from bypassing the piston head as it moves within a cylinder. The choice between single-acting and double-acting designs dictates how this function is achieved.

How a Single-Acting Seal Works

A single-acting seal has an asymmetric design, optimized to be energized by pressure from only one side.

When pressure is applied from its designated direction, the seal lip is forced against the cylinder wall, creating a tight barrier. Pressure from the opposite direction will typically bypass the seal.

For this reason, if a piston needs to seal during both extension and retraction, two single-acting seals are often installed back-to-back in separate grooves.

How a Double-Acting Seal Works

A double-acting seal features a symmetrical profile, allowing it to seal pressure effectively from either direction.

This design enables a single seal to manage the forces of both the push and pull strokes of a piston. It simplifies the piston design by requiring only one groove.

Key Factors in Seal Selection

Your choice is not just about the seal itself but about the design and performance of the entire hydraulic or pneumatic system.

Application Demands: Force Direction

The most critical factor is whether the actuator needs to apply force in one direction or two.

Systems like simple lifting jacks or clamping mechanisms often only require force on the extension stroke, making a single-acting seal ideal.

Conversely, actuators used for steering, positioning, or complex automation require precise control in both directions, making a double-acting seal the standard choice.

System Complexity and Piston Design

A double-acting seal simplifies the piston head by requiring only one seal groove. This reduces machining complexity and component count.

Using two single-acting seals requires two separate grooves, increasing machining costs and assembly time. However, this configuration can sometimes offer performance benefits in very specific high-performance applications.

Understanding the Trade-offs

Choosing a seal involves balancing cost, performance, and design simplicity. There is no universally "better" option, only the one that is correct for the specific job.

Cost vs. Simplicity

Individually, a single-acting seal is generally less expensive than a double-acting one due to its simpler construction.

However, if your application requires bidirectional sealing, using a single double-acting seal is almost always more cost-effective than machining two grooves and installing two single-acting seals.

Performance Under Stress

As noted in industry analysis, double-acting seals are often preferred for applications involving high pressure, significant mechanical stress, or high speeds.

Their robust, single-component design provides excellent stability and resistance to wear in demanding, bidirectional cycles.

Making the Right Choice for Your Application

To select the correct seal, analyze the primary function of your cylinder.

- If your primary focus is unidirectional force (e.g., lifting, clamping, pressing): A single-acting seal provides the most direct and cost-effective solution.

- If your primary focus is bidirectional control (e.g., steering, positioning, articulating arms): A double-acting seal simplifies the design and provides reliable, two-way performance.

- If your primary focus is minimizing components and assembly complexity: A double-acting seal is the superior choice, as it consolidates sealing for both strokes into one component.

Understanding whether the force is applied in one direction or two is the key to selecting the correct piston seal for your system.

Summary Table:

| Feature | Single-Acting Seal | Double-Acting Seal |

|---|---|---|

| Sealing Direction | One direction only | Both directions (push & pull) |

| Typical Application | Lifting, clamping, pressing | Steering, positioning, automation |

| Piston Design | Requires two grooves for bidirectional sealing | Requires one groove |

| Cost Consideration | Lower per-seal cost, higher assembly cost for bidirectional use | Higher per-seal cost, lower overall system cost for bidirectional use |

| Best For | Simple, unidirectional force applications | Complex, bidirectional control and high-stress applications |

Need High-Performance PTFE Seals for Your Application?

Whether your design requires reliable single-acting or robust double-acting seals, KINTEK's precision-engineered PTFE components deliver exceptional performance. We specialize in custom fabricating seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors.

Let us provide the perfect sealing solution for your project, from prototypes to high-volume production.

Contact our experts today for a consultation!

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- How does PTFE react to ammonia? Discover Its Superior Chemical Resistance

- How does PTFE perform in chemically corrosive environments? Unmatched Chemical Immunity & Reliability

- How do PTFE properties benefit butterfly valve performance? Enhance Durability & Efficiency

- What are the key features of PTFE-lined bottle caps? Ensure Chemical Integrity and Purity for Your Samples

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications