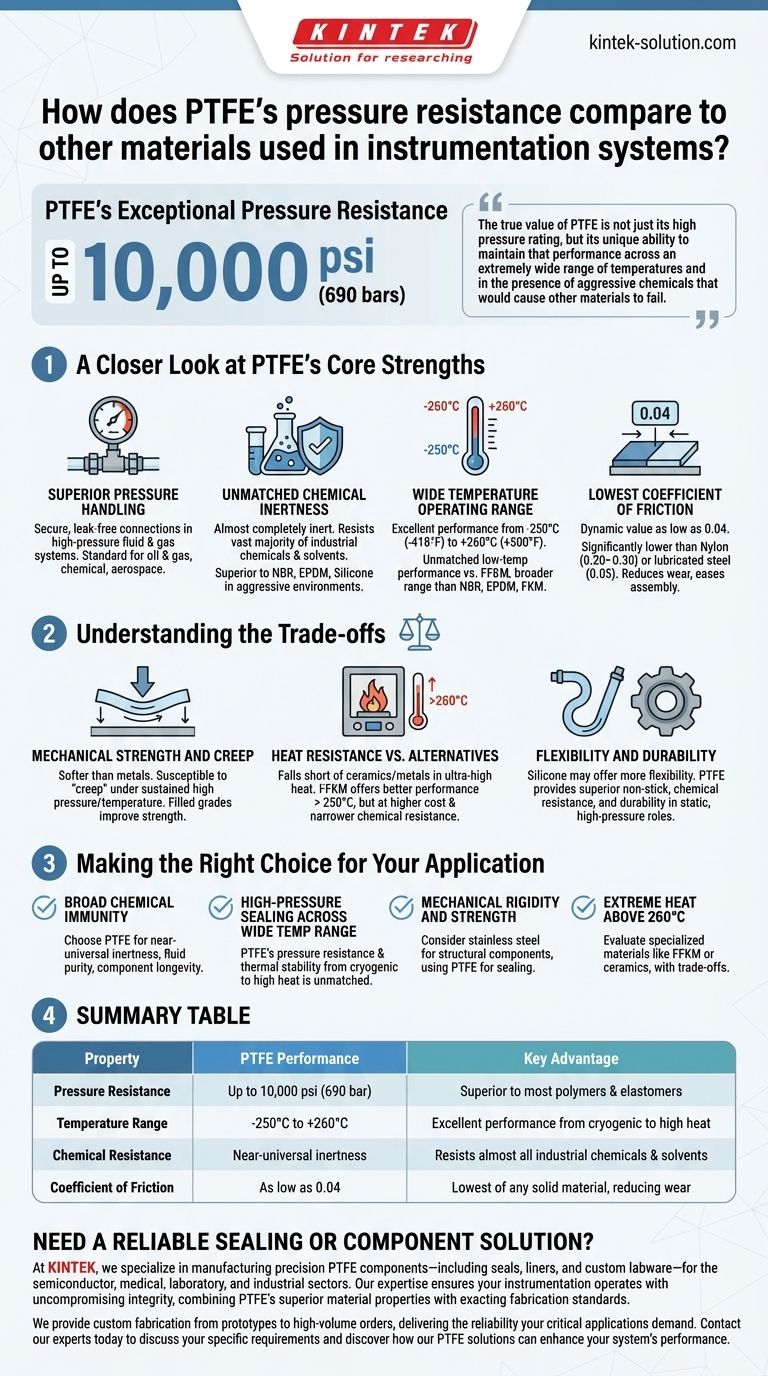

In instrumentation systems, PTFE offers exceptional pressure resistance. It is capable of withstanding pressures up to 10,000 psi (690 bars), a rating that is superior to many other polymer and elastomeric materials commonly used in demanding industrial applications.

The true value of PTFE is not just its high pressure rating, but its unique ability to maintain that performance across an extremely wide range of temperatures and in the presence of aggressive chemicals that would cause other materials to fail.

A Closer Look at PTFE's Core Strengths

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer often specified for critical components like tubing, fittings, and seals in instrumentation systems. Its properties make it a benchmark material for reliability in harsh environments.

### Superior Pressure Handling

PTFE's molecular structure allows it to form secure, leak-free connections in high-pressure fluid and gas systems.

This makes it a standard choice for applications in sectors like oil and gas, chemical processing, and aerospace where system integrity is non-negotiable.

### Unmatched Chemical Inertness

Pure PTFE is almost completely inert, remaining highly insoluble and non-reactive with the vast majority of industrial chemicals and solvents.

Only a few highly specialized chemicals, such as alkali metals or certain fluorine agents under extreme conditions, can affect it. This makes it far superior to materials like NBR, EPDM, or even silicone in chemically aggressive environments.

### Wide Temperature Operating Range

PTFE maintains its properties across an exceptionally broad temperature spectrum, from -250°C to +260°C (-418°F to +500°F).

While materials like FFKM can exceed its upper temperature limit (up to 340°C), they do not offer PTFE's excellent low-temperature performance. Other common elastomers like NBR, EPDM, and FKM operate within much narrower thermal windows.

### The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, with a dynamic value as low as 0.04.

This is significantly lower than other engineering polymers like Nylon (0.20–0.30) or even lubricated steel (0.05). This property reduces wear in dynamic seals and makes assembling and disassembling fittings easier.

Understanding the Trade-offs

No material is perfect for every scenario. While PTFE's performance is impressive, it's crucial to understand its limitations to make an informed decision.

### Mechanical Strength and Creep

Compared to metals like stainless steel, PTFE is a much softer material.

Under sustained high pressure and temperature, pure PTFE can be susceptible to "creep" or cold flow, where the material slowly deforms over time. For structural applications, filled grades of PTFE are often used to improve mechanical strength and resistance to creep.

### Heat Resistance vs. Alternatives

While its 260°C upper limit is excellent for a polymer, it falls short of materials like ceramics or metals in ultra-high-temperature applications.

Similarly, specialty elastomers like FFKM offer better performance in environments consistently above 250°C, though typically at a significantly higher cost and with a narrower chemical resistance profile.

### Flexibility and Durability

Silicone coatings can offer greater flexibility than PTFE, which may be a factor in applications requiring constant movement.

However, PTFE generally provides superior non-stick performance, chemical resistance, and durability compared to silicone in static, high-pressure instrumentation roles.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with the primary demands of your system.

- If your primary focus is broad chemical immunity: Choose PTFE for its near-universal inertness, which ensures fluid purity and component longevity.

- If your primary focus is high-pressure sealing across a wide temperature range: PTFE's combination of pressure resistance and thermal stability from cryogenic lows to high heat is unmatched by most other polymers.

- If your primary focus is mechanical rigidity and strength: Consider stainless steel for fittings and structural components, potentially using PTFE for the sealing elements within them.

- If your primary focus is extreme heat above 260°C (500°F): Evaluate specialized materials like FFKM or ceramics, but be prepared for trade-offs in cost, low-temperature performance, and chemical compatibility.

Ultimately, PTFE's high pressure rating, combined with its elite chemical and thermal resistance, makes it a uniquely reliable choice for the most demanding instrumentation challenges.

Summary Table:

| Property | PTFE Performance | Key Advantage |

|---|---|---|

| Pressure Resistance | Up to 10,000 psi (690 bar) | Superior to most polymers & elastomers |

| Temperature Range | -250°C to +260°C | Excellent performance from cryogenic to high heat |

| Chemical Resistance | Near-universal inertness | Resists almost all industrial chemicals & solvents |

| Coefficient of Friction | As low as 0.04 | Lowest of any solid material, reducing wear |

Need a reliable sealing or component solution for your high-pressure, high-purity system?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your instrumentation operates with uncompromising integrity, combining PTFE's superior material properties with exacting fabrication standards.

We provide custom fabrication from prototypes to high-volume orders, delivering the reliability your critical applications demand.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can enhance your system's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance