PTFE bars are a cornerstone material in a wide range of demanding industries due to their unique combination of properties. They are successfully and widely applied in chemical and petrochemical processing, pharmaceutical and medical manufacturing, food and beverage production, and high-tech sectors like aerospace and electronics.

The widespread adoption of PTFE is not due to a single trait, but its powerful combination of near-universal chemical inertness, high-temperature tolerance, and extremely low friction. This makes it a default choice for components that must perform reliably in hostile environments where other materials would fail.

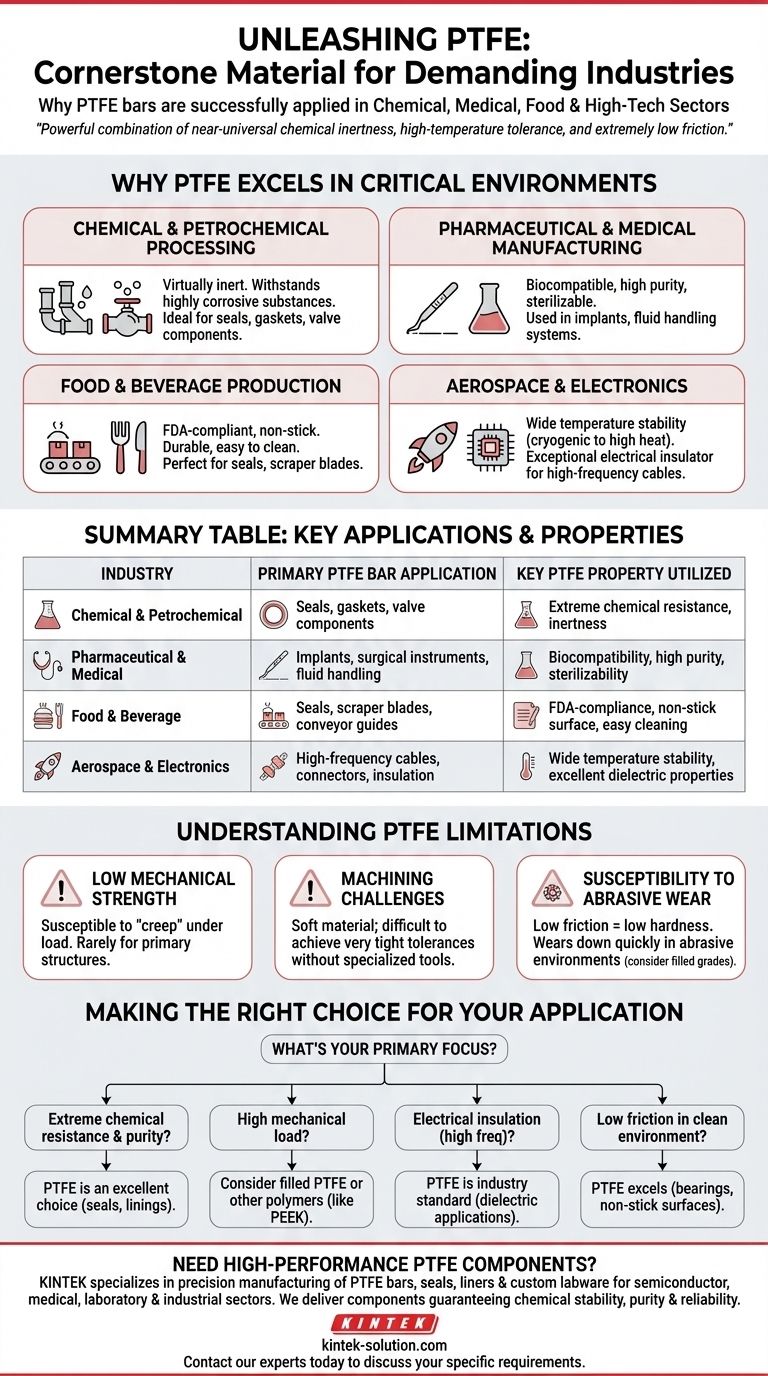

Why PTFE Excels in Demanding Environments

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer. Its value comes from a molecular structure that gives it a set of properties highly sought after for critical components.

Chemical and Petrochemical Processing

In this sector, equipment must withstand constant exposure to highly corrosive substances.

PTFE is virtually inert and is not attacked by the vast majority of industrial chemicals, acids, and solvents. This makes it ideal for manufacturing seals, gaskets, and valve components that ensure the safe handling of hazardous materials.

Pharmaceutical and Medical Manufacturing

Purity and non-contamination are non-negotiable in medical and pharmaceutical applications.

PTFE is biocompatible, meaning it does not react with bodily tissues or fluids, making it suitable for implants and surgical instruments. Its high purity and ability to be sterilized are critical for fluid handling systems and processing equipment where preventing contamination is paramount.

Food and Beverage Production

This industry requires materials that are both durable and safe for contact with consumables.

PTFE is FDA-compliant for food contact applications. Its non-stick surface prevents buildup and allows for easy, thorough cleaning, while its resistance to harsh cleaning agents ensures a long service life for components like seals, scraper blades, and conveyor guides.

Aerospace and Electronics

High-tech applications demand materials that perform under extreme conditions.

In aerospace, PTFE is valued for its stability across a wide range of temperatures, from cryogenic levels to high heat. In electronics, its outstanding dielectric properties make it an exceptional electrical insulator, perfect for high-frequency cables and connectors where signal integrity is key.

Understanding the Limitations of PTFE

While incredibly versatile, PTFE is not the solution for every engineering problem. Understanding its trade-offs is essential for successful application.

Low Mechanical Strength

PTFE is a relatively soft material with a low tensile strength compared to other engineering plastics or metals.

It is susceptible to "creep," which is the tendency to deform slowly over time when under a constant load. For this reason, it is rarely used for primary structural components.

Machining and Tolerances

The softness of PTFE can also present challenges during machining.

While it is easy to cut, achieving very tight dimensional tolerances can be difficult without specialized tooling and techniques. Its high coefficient of thermal expansion must also be factored into any design that will experience temperature swings.

Susceptibility to Abrasive Wear

PTFE’s low friction comes at the cost of low hardness. In environments with abrasive particles, it can wear down more quickly than harder materials.

To counter this, "filled" grades of PTFE are often used. These combine PTFE with additives like glass, carbon, or bronze to significantly improve wear resistance and mechanical strength.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary demands of your project.

- If your primary focus is extreme chemical resistance and purity: PTFE is one of the best choices available, especially for seals, linings, and fluid-handling components.

- If your primary focus is high mechanical load or structural integrity: Pure PTFE is likely unsuitable, and you should consider a filled grade of PTFE or a different engineering polymer like PEEK.

- If your primary focus is electrical insulation at high frequencies: PTFE is an industry standard and an exceptional choice for dielectric applications.

- If your primary focus is low friction in a clean environment: PTFE excels as a material for bearings, slide plates, and non-stick surfaces.

Ultimately, PTFE's success stems from its ability to solve problems where chemical stability, temperature range, and purity are the most critical factors.

Summary Table:

| Industry | Primary PTFE Bar Application | Key PTFE Property Utilized |

|---|---|---|

| Chemical & Petrochemical | Seals, gaskets, valve components | Extreme chemical resistance, inertness |

| Pharmaceutical & Medical | Implants, surgical instruments, fluid handling | Biocompatibility, high purity, sterilizability |

| Food & Beverage | Seals, scraper blades, conveyor guides | FDA-compliance, non-stick surface, easy cleaning |

| Aerospace & Electronics | High-frequency cables, connectors, insulation | Wide temperature stability, excellent dielectric properties |

Need high-performance PTFE components for your critical application?

KINTEK specializes in the precision manufacturing of PTFE bars, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We understand the demanding environments you operate in and deliver components that guarantee chemical stability, purity, and reliability—from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can enhance your project's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE bushings? Critical Solutions for Demanding Industries

- What are the mechanical properties of PTFE balls? Leverage Low Friction & Chemical Resistance

- What is PTFE and why is it used in sealing applications? Unlock Superior Chemical & Temperature Resistance

- What are the primary applications of PTFE expansion bellows? Protect Piping Systems from Stress & Corrosion

- Why is PTFE valuable in aerospace applications? Key Benefits for Safer, Lighter Aircraft

- What customization options are available for PTFE rotary shaft seals? Tailor for High Performance

- What are the main advantages of PTFE processing machines? Achieve Superior Component Performance

- What industries commonly use expanded PTFE gaskets? A Guide to Critical Sealing Solutions