At their core, the main advantages of PTFE processing machines are their ability to harness the material's exceptional properties, delivering components with strong corrosion resistance, high-temperature stability, a very low friction coefficient, and high dimensional precision. These machines are specifically engineered to shape PTFE effectively, a material that is otherwise challenging to work with, turning its unique characteristics into reliable, high-performance parts.

The true value of a PTFE processing machine is not in the machine itself, but in its unique capability to translate the remarkable chemical and thermal properties of Polytetrafluoroethylene (PTFE) into precisely manufactured components for the most demanding applications.

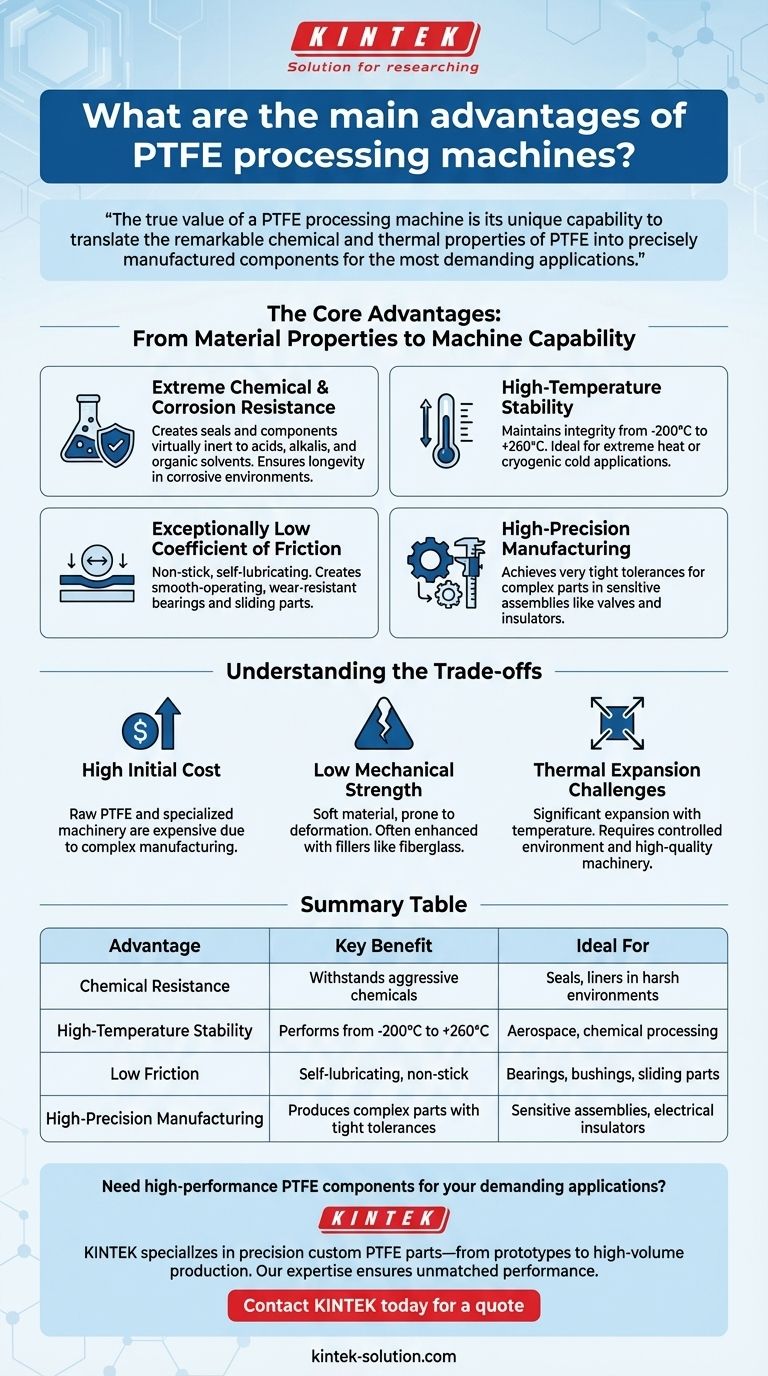

The Core Advantages: From Material Properties to Machine Capability

The advantages of these specialized machines are directly derived from the inherent qualities of the PTFE material they are designed to process. The machine's role is to achieve precision without compromising these elite properties.

Extreme Chemical and Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, alkalis, and organic solvents.

A PTFE processing machine allows you to create seals, gaskets, linings, and fluid-handling components that will not degrade, even in the most corrosive environments. This ensures operational reliability and longevity where other materials would fail.

High-Temperature Stability

PTFE maintains its integrity over an exceptionally wide temperature range, typically from -200°C up to +260°C (-328°F to +500°F).

This allows machines to produce parts for applications involving extreme heat or cryogenic cold, such as in aerospace, chemical processing, and industrial manufacturing.

An Exceptionally Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material, making it extremely non-stick and self-lubricating.

Processing machines leverage this property to create high-performance bearings, bushings, and sliding parts that operate smoothly and resist wear, often eliminating the need for external lubricants.

High-Precision Manufacturing

Specialized PTFE processing machines are built to handle the unique challenges of the material and achieve very tight tolerances.

This precision is critical for creating complex parts with consistent, reliable dimensions, ensuring they fit and function correctly in sensitive assemblies like valves and electrical insulators.

Understanding the Trade-offs

While the benefits are significant, it is crucial to understand the challenges associated with PTFE and its processing to make an informed decision. These are not failures of the machines, but realities of the material they handle.

High Initial Cost

Both the raw PTFE material and the specialized machinery required to process it are expensive. This is due to the complex manufacturing process of the polymer itself.

The initial investment can be a significant factor, making it best suited for applications where its unique properties are a strict requirement.

Low Mechanical Strength

Compared to engineering metals or other polymers, PTFE is a relatively soft material with lower tensile strength and wear resistance. It can be prone to deformation under high loads.

To counteract this, fillers like fiberglass, carbon, or graphite are often added to create composite PTFE grades with enhanced mechanical properties.

Thermal Expansion Challenges

PTFE has a high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes.

A high-quality processing machine and a controlled environment are essential to manage this expansion during manufacturing, ensuring the final part meets its required dimensional specifications.

Making the Right Choice for Your Application

Ultimately, the decision to use components made by a PTFE processing machine depends entirely on the demands of your specific project.

- If your primary focus is reliability in harsh chemical environments: PTFE's chemical inertness is its most powerful advantage, providing unparalleled resistance to corrosion.

- If your primary focus is performance in high-temperature applications: Its wide operating temperature range ensures stability where many other plastics would melt or become brittle.

- If your primary focus is creating low-friction moving parts: PTFE's non-stick, self-lubricating nature is ideal for bearings, seals, and sliding mechanisms.

- If your primary focus is structural integrity under high mechanical load: You should consider filled grades of PTFE or alternative materials, as pure PTFE is relatively soft.

Choosing to leverage PTFE processing is a decision to prioritize performance and reliability in environments where conventional materials are simply not an option.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Withstands aggressive acids, alkalis, and solvents. | Seals, liners, and fluid-handling components in harsh environments. |

| High-Temperature Stability | Performs from -200°C to +260°C. | Aerospace, chemical processing, and industrial manufacturing. |

| Low Friction | Self-lubricating with a very low coefficient of friction. | Bearings, bushings, and non-stick sliding parts. |

| High-Precision Manufacturing | Produces complex parts with tight tolerances. | Sensitive assemblies like valves and electrical insulators. |

Need high-performance PTFE components for your demanding applications?

KINTEK specializes in the precision manufacturing of custom PTFE parts—from prototypes to high-volume production. Our expertise in processing this challenging material ensures your components deliver unmatched chemical resistance, thermal stability, and low friction.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can help you leverage the unique properties of PTFE for reliable, long-lasting performance.

Contact KINTEK today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Evaporating Dishes for Diverse Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers