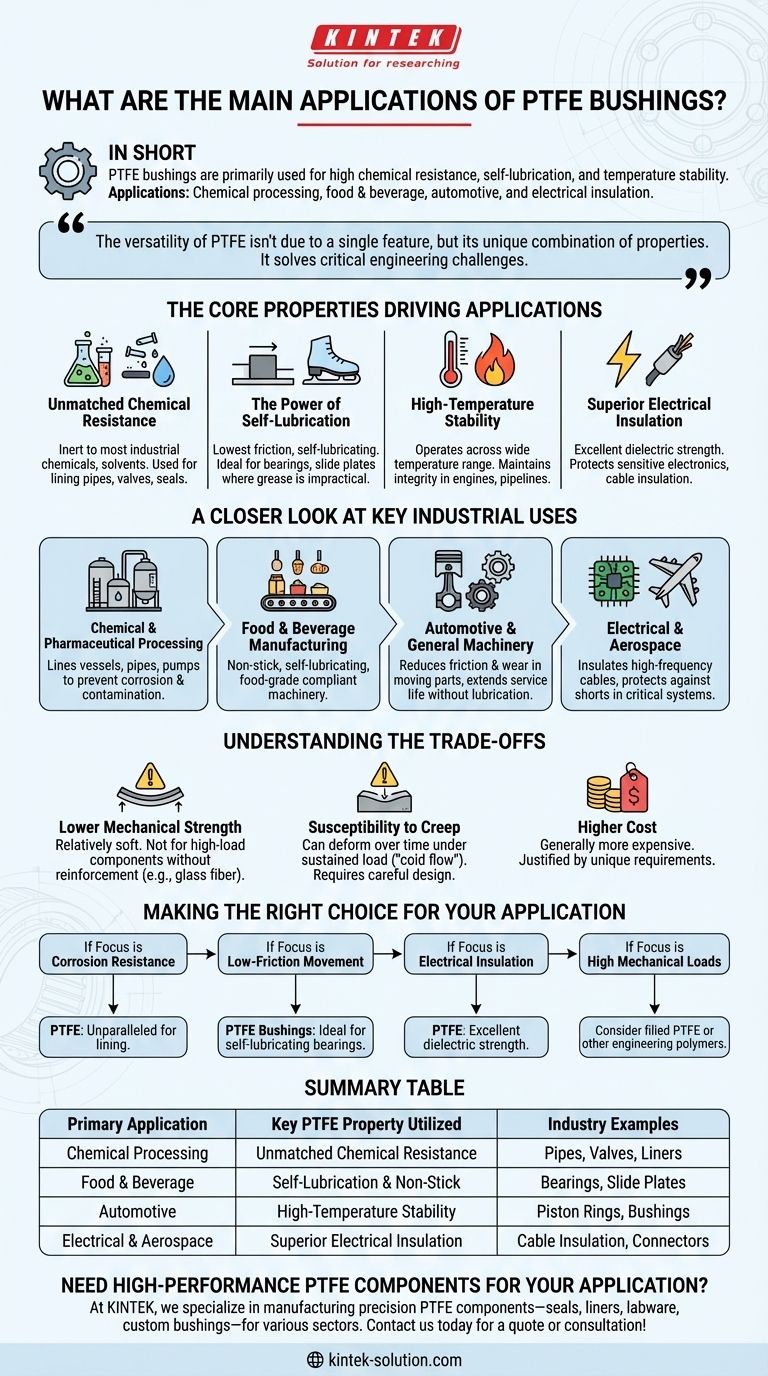

In short, PTFE bushings are primarily used in applications demanding high chemical resistance, self-lubrication, and temperature stability. Their main applications are found in chemical processing equipment, food and beverage machinery, automotive components, and for electrical insulation in sensitive electronics and aerospace systems.

The versatility of PTFE isn't due to a single feature, but its unique combination of properties. It solves critical engineering challenges in environments where other materials would quickly fail due to corrosion, friction, or extreme temperatures.

The Core Properties Driving PTFE Bushing Applications

To understand where PTFE bushings are used, we must first understand why they are chosen. Their applications are a direct result of a few powerful material characteristics.

Unmatched Chemical Resistance

PTFE is almost completely inert, meaning it does not react with the vast majority of industrial chemicals and solvents. This makes it an essential material for equipment that handles corrosive substances.

This property is critical in chemical processing plants, oil and gas pipelines, and pharmaceutical manufacturing for lining pipes, valves, and seals.

The Power of Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This allows it to function as a self-lubricating surface.

This is why PTFE is the material of choice for bearings, bushings, slide plates, and gears in machinery where external lubricants like grease or oil are impractical or undesirable, such as in food processing.

High-Temperature Stability

PTFE can operate effectively across a very wide temperature range without degrading. Its high melting point allows it to maintain structural integrity in demanding environments.

This makes it suitable for components in automotive engines, industrial pipelines, and processing equipment that experience significant heat.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. It resists the flow of electricity, making it ideal for protecting sensitive electronic components.

You will find it used for wire and cable insulation in the aerospace and computer industries, where signal integrity and reliability are paramount.

A Closer Look at Key Industrial Uses

These core properties translate directly into specific, high-value applications across several major industries.

In Chemical and Pharmaceutical Processing

Because of its non-reactive nature, PTFE is used extensively to line vessels, pipes, pumps, and valves. It prevents both corrosion of the equipment and contamination of the product.

In Food and Beverage Manufacturing

The non-stick and self-lubricating properties of PTFE are perfect for machinery that processes food. It prevents product buildup and eliminates the need for food-grade lubricants, while also complying with regulatory standards.

In Automotive and General Machinery

PTFE bushings and bearings reduce friction and wear in moving parts like piston rings and slide plates. This improves efficiency and extends the service life of components without requiring traditional lubrication.

In Electrical and Aerospace

As a superior insulator, PTFE is used to wrap high-frequency cables and wires. This protects against signal loss and electrical shorts in critical systems, from consumer electronics to advanced aerospace applications.

Understanding the Trade-offs

While powerful, PTFE is not the solution for every problem. An objective assessment requires understanding its limitations.

Lower Mechanical Strength

Compared to engineering plastics like nylon or PEEK, pure PTFE is relatively soft. It is not suitable for high-load structural components without reinforcement from fillers like glass fiber or bronze.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time, a phenomenon known as "creep" or "cold flow." This must be accounted for in the design of parts that will be under continuous pressure.

Higher Cost

PTFE is generally more expensive than many commodity plastics. Its use is typically justified in applications where its unique combination of properties is a strict requirement, not just a preference.

Making the Right Choice for Your Application

Selecting the right material depends entirely on your primary engineering goal.

- If your primary focus is corrosion resistance: PTFE is an unparalleled choice for lining pipes, valves, and containers exposed to aggressive chemicals.

- If your primary focus is low-friction movement: PTFE bushings are ideal for self-lubricating bearings and slide plates, especially in clean environments like food or pharma.

- If your primary focus is electrical insulation: PTFE provides excellent dielectric strength for high-frequency cables and critical electronic components.

- If your primary focus is high mechanical loads: You should consider a filled grade of PTFE or a different engineering polymer with greater structural rigidity.

Understanding these key properties and their trade-offs empowers you to select the right material for the right job, ensuring reliability and performance.

Summary Table:

| Primary Application | Key PTFE Property Utilized | Industry Examples |

|---|---|---|

| Chemical Processing | Unmatched Chemical Resistance | Pipes, Valves, Liners |

| Food & Beverage Machinery | Self-Lubrication & Non-Stick | Bearings, Slide Plates |

| Automotive Components | High-Temperature Stability | Piston Rings, Bushings |

| Electrical & Aerospace Systems | Superior Electrical Insulation | Cable Insulation, Connectors |

Need high-performance PTFE components for your application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom bushings—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your components meet the exact demands of chemical resistance, self-lubrication, and temperature stability.

Let’s solve your toughest engineering challenges together. Contact us today for a quote or consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry