At its core, expanded PTFE (ePTFE) is the sealing material of choice for industries where failure is not an option. It is most commonly used in the chemical processing, petrochemical, pharmaceutical, and food & beverage industries due to its unparalleled chemical resistance and ability to maintain a reliable seal under extreme conditions.

The decision to use an expanded PTFE gasket is driven by the need for a seal that can simultaneously resist aggressive chemicals, withstand a vast range of temperatures, and conform to imperfect surfaces where other materials would fail.

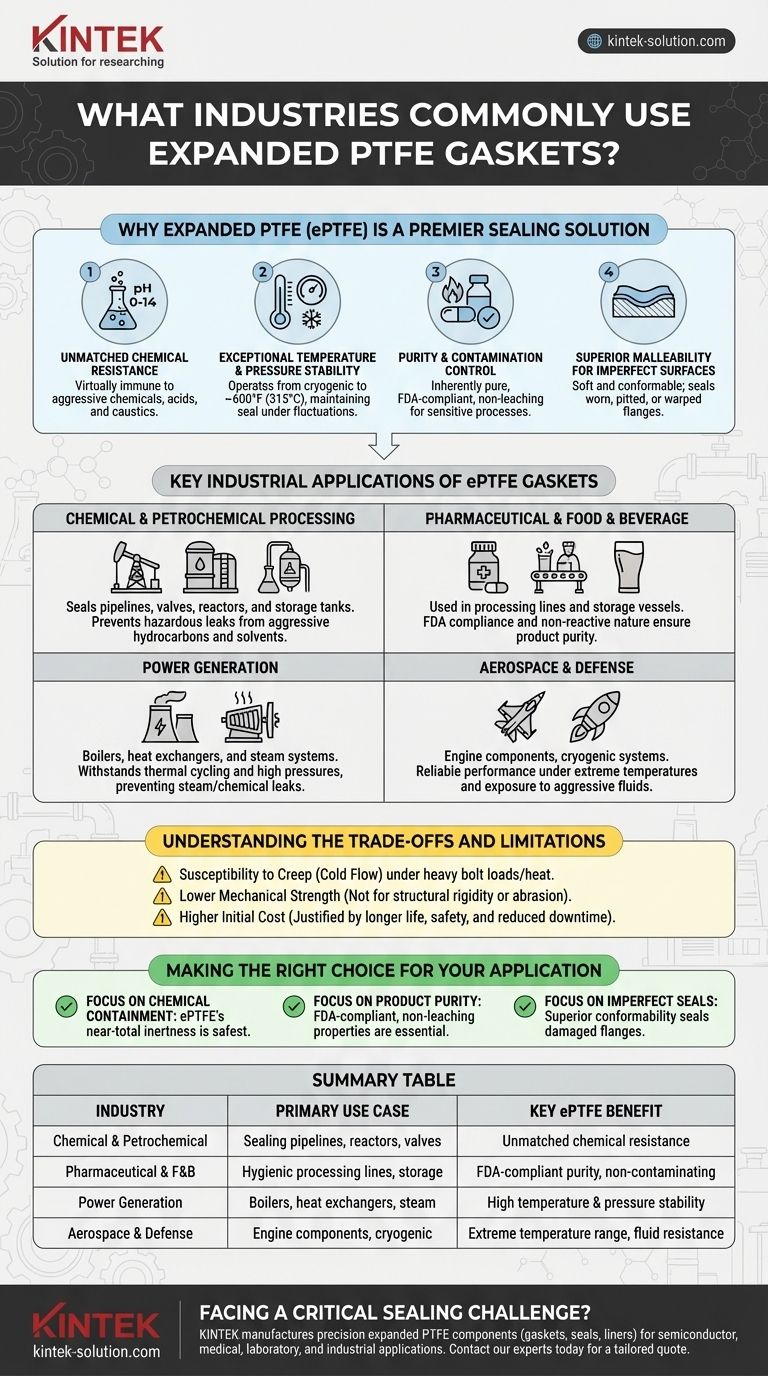

Why Expanded PTFE Is a Premier Sealing Solution

Expanded PTFE is created by rapidly stretching standard PTFE, which alters its molecular structure. This process creates a microporous, fibrous material that is exceptionally strong yet soft and highly conformable.

Unmatched Chemical Resistance

Expanded PTFE inherits the remarkable chemical inertness of standard PTFE. It is virtually immune to attack from the most aggressive chemicals, acids, and caustics across the entire pH range (0-14).

This property makes it indispensable for applications involving corrosive media that would rapidly degrade lesser materials.

Exceptional Temperature and Pressure Stability

ePTFE gaskets can operate effectively in a very wide thermal window, from cryogenic temperatures up to approximately 600°F (315°C).

This stability allows them to maintain a reliable seal in systems that experience significant temperature fluctuations or operate at consistently high pressures, such as in steam lines or chemical reactors.

Purity and Contamination Control

The material is inherently pure and does not leach contaminants. Many grades of ePTFE are FDA-compliant, making them a mandatory choice for industries where product purity is paramount.

This ensures that the gasket itself does not become a source of contamination in sensitive processes like pharmaceutical manufacturing or food processing.

Superior Malleability for Imperfect Surfaces

Perhaps the most significant advantage of the "expanded" form is its softness and conformability. ePTFE gaskets can create a tight seal on flange surfaces that are worn, pitted, or warped.

While a rigid gasket would fail on an imperfect surface, the soft fibers of ePTFE flow into minor imperfections, ensuring a tight, long-lasting seal with lower bolt torque.

Key Industrial Applications of ePTFE Gaskets

The unique combination of these properties makes ePTFE a problem-solver across several demanding sectors.

Chemical and Petrochemical Processing

In this sector, gaskets are constantly exposed to aggressive hydrocarbons, solvents, and corrosive chemicals.

ePTFE is used to seal pipelines, valves, reactors, and storage tanks, preventing hazardous leaks and ensuring operational safety.

Pharmaceutical and Food & Beverage

Purity is the primary concern here. ePTFE's FDA compliance and non-reactive nature ensure it will not contaminate the product batch.

It is used extensively in processing lines, storage vessels, and equipment where hygienic conditions must be maintained.

Power Generation

Power plants operate under high pressures and temperatures. ePTFE gaskets are used in boilers, heat exchangers, and steam turbine systems.

Their ability to withstand thermal cycling and maintain a seal prevents costly and dangerous steam or chemical leaks.

Aerospace and Defense

These industries require materials that perform reliably under extreme conditions, from engine components exposed to jet fuel to cryogenic systems.

ePTFE's wide operating temperature range and resistance to aggressive fluids make it a critical component for ensuring system integrity.

Understanding the Trade-offs and Limitations

While highly effective, ePTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Susceptibility to Creep

The primary trade-off for ePTFE's excellent conformability is a higher potential for creep, or "cold flow."

Under heavy, sustained bolt loads, especially at elevated temperatures, the material can slowly deform over time. This can lead to a loss of sealing stress, requiring careful engineering and proper installation torque to mitigate.

Lower Mechanical Strength

ePTFE is a soft material. It is not designed for applications that require structural rigidity or resistance to significant mechanical abrasion.

Higher Initial Cost

Compared to common elastomer or fiber-based gaskets, ePTFE represents a higher upfront material cost.

This cost is typically justified by its longer service life, reduced downtime, and enhanced safety in critical applications.

Making the Right Choice for Your Application

Selecting the correct gasket material is a function of your primary operational goal.

- If your primary focus is containing aggressive chemicals: ePTFE's near-total chemical inertness makes it one of the safest and most reliable choices.

- If your primary focus is ensuring absolute product purity: The FDA-compliant and non-leaching properties of ePTFE are essential for food, beverage, and pharmaceutical applications.

- If your primary focus is sealing old, damaged, or warped flanges: The superior conformability of ePTFE can create a reliable seal where more rigid materials would fail.

Ultimately, choosing an ePTFE gasket is an investment in operational reliability for your most critical sealing challenges.

Summary Table:

| Industry | Primary Use Case | Key ePTFE Benefit |

|---|---|---|

| Chemical & Petrochemical | Sealing pipelines, reactors, valves | Unmatched chemical resistance to aggressive media |

| Pharmaceutical & Food & Beverage | Hygienic processing lines, storage vessels | FDA-compliant purity, non-contaminating |

| Power Generation | Boilers, heat exchangers, steam systems | High temperature & pressure stability |

| Aerospace & Defense | Engine components, cryogenic systems | Extreme temperature range, fluid resistance |

Facing a critical sealing challenge? KINTEK manufactures precision expanded PTFE components (gaskets, seals, liners) for semiconductor, medical, laboratory, and industrial applications. Our custom fabrication—from prototypes to high-volume orders—ensures you get a reliable, application-specific solution that enhances safety and reduces downtime. Contact our experts today to discuss your requirements and receive a tailored quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support