At its core, Polytetrafluoroethylene (PTFE) is invaluable in aerospace because it provides a rare combination of properties that directly solve critical engineering challenges. Its value comes from its ability to function as an exceptional electrical insulator, a high-temperature resistant material, and one of the lowest-friction surfaces known, all while being lightweight and chemically inert.

The challenge in aerospace is finding materials that perform reliably under extreme conditions without adding prohibitive weight. PTFE's value lies not in a single attribute, but in its unique synergy of thermal, electrical, and mechanical properties that lead to safer, lighter, and more durable aircraft components.

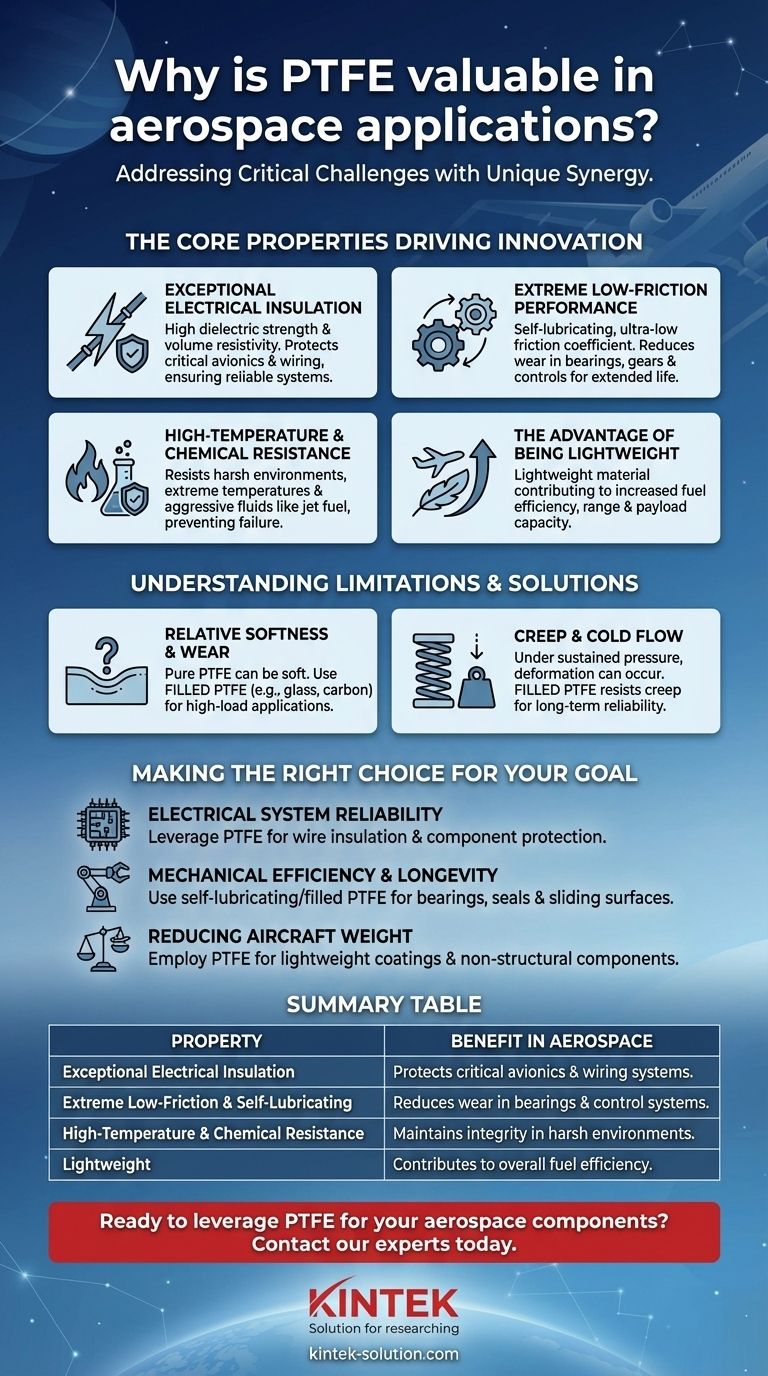

The Core Properties Driving Aerospace Innovation

To understand PTFE's role, we must examine how its specific characteristics translate into tangible benefits for an aircraft, from its electrical systems to its moving parts.

Exceptional Electrical Insulation

PTFE possesses an extremely high dielectric strength and volume resistivity (greater than 10¹⁸ ohm-cm), making it one of the best electrical insulators available.

This property is not just a minor benefit; it is fundamental to the safety and reliability of modern aircraft. It is used to insulate critical wiring and protect sensitive avionics from electrical interference, ensuring the integrity of communication, navigation, and control systems.

Extreme Low-Friction Performance

With an exceptionally low coefficient of friction, PTFE is an ideal material for applications where smooth, consistent movement is essential.

Its self-lubricating nature ensures that components like bearings, gears, and sliding elements in aircraft control systems operate with minimal resistance. This reduces wear and tear, extends the service life of parts, and improves overall operational efficiency.

High-Temperature and Chemical Resistance

Aerospace environments are harsh, involving extreme temperature fluctuations and exposure to aggressive fluids like jet fuel, hydraulic oils, and de-icing agents.

PTFE maintains its integrity and properties across a wide temperature range and is almost universally chemically inert. This durability makes it ideal for coating engine components and creating seals that will not degrade under stress, preventing leaks and component failure.

The Advantage of Being Lightweight

In aerospace, every gram matters. Reducing an aircraft's weight directly translates to increased fuel efficiency, range, and payload capacity.

PTFE provides its high-performance properties in a lightweight form. Using it for coatings, liners, and even small components contributes to the overall goal of weight reduction without compromising on durability or safety.

Understanding the Practical Limitations

While its benefits are significant, it is crucial to recognize that pure PTFE is not a universal solution. An objective assessment requires understanding its trade-offs.

Relative Softness and Wear

In its pure, unfilled state, PTFE is a relatively soft material. In high-load, high-wear applications, it can be susceptible to abrasion and deformation.

To counteract this, engineers use filled PTFE. By adding materials like glass, carbon, or bronze, they can dramatically enhance its wear resistance and dimensional stability, making it suitable for demanding components like bearings in aircraft control systems.

Creep and Cold Flow

Under sustained pressure, PTFE can exhibit "creep," or a tendency to slowly deform over time. This is a critical consideration for components that must maintain precise dimensional tolerances.

Again, the use of fillers is the primary solution. Formulations like glass-filled PTFE are specifically designed to resist creep and maintain their shape under high loads, ensuring long-term reliability.

Making the Right Choice for Your Goal

Applying PTFE effectively requires aligning its specific strengths with your primary engineering objective.

- If your primary focus is electrical system reliability: Leverage PTFE's dielectric properties for superior wire insulation and protection for sensitive electronic components.

- If your primary focus is mechanical efficiency and longevity: Use self-lubricating PTFE or filled PTFE for bearings, seals, and sliding surfaces to reduce friction and extend component life.

- If your primary focus is reducing aircraft weight: Employ PTFE as a lightweight coating for engine parts or as a material for non-structural components to decrease overall fuel burn.

Ultimately, PTFE's versatility makes it a critical and enabling material in the ongoing pursuit of safer, lighter, and more reliable aerospace technology.

Summary Table:

| Property | Benefit in Aerospace |

|---|---|

| Exceptional Electrical Insulation | Protects critical avionics and wiring systems. |

| Extreme Low-Friction & Self-Lubricating | Reduces wear in bearings and control systems, improving longevity. |

| High-Temperature & Chemical Resistance | Maintains integrity in harsh environments, preventing component failure. |

| Lightweight | Contributes to overall fuel efficiency and increased payload capacity. |

Ready to leverage PTFE for your aerospace components?

KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the aerospace, semiconductor, medical, and industrial sectors. We combine material expertise with custom fabrication capabilities, from prototypes to high-volume orders, to help you achieve safer, lighter, and more reliable designs.

Contact our experts today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments