Yes, absolutely. PTFE envelope gaskets are frequently custom-made to accommodate a wide range of specific industrial requirements. This customization extends beyond simple dimensions to include the gasket's core materials and manufacturing style, ensuring an optimal seal for specialized and demanding applications.

The ability to customize a PTFE envelope gasket is its core strength. True optimization comes not just from fitting the dimensions, but from selecting the right combination of the PTFE envelope and its inner core to precisely match your application's chemical, thermal, and pressure demands.

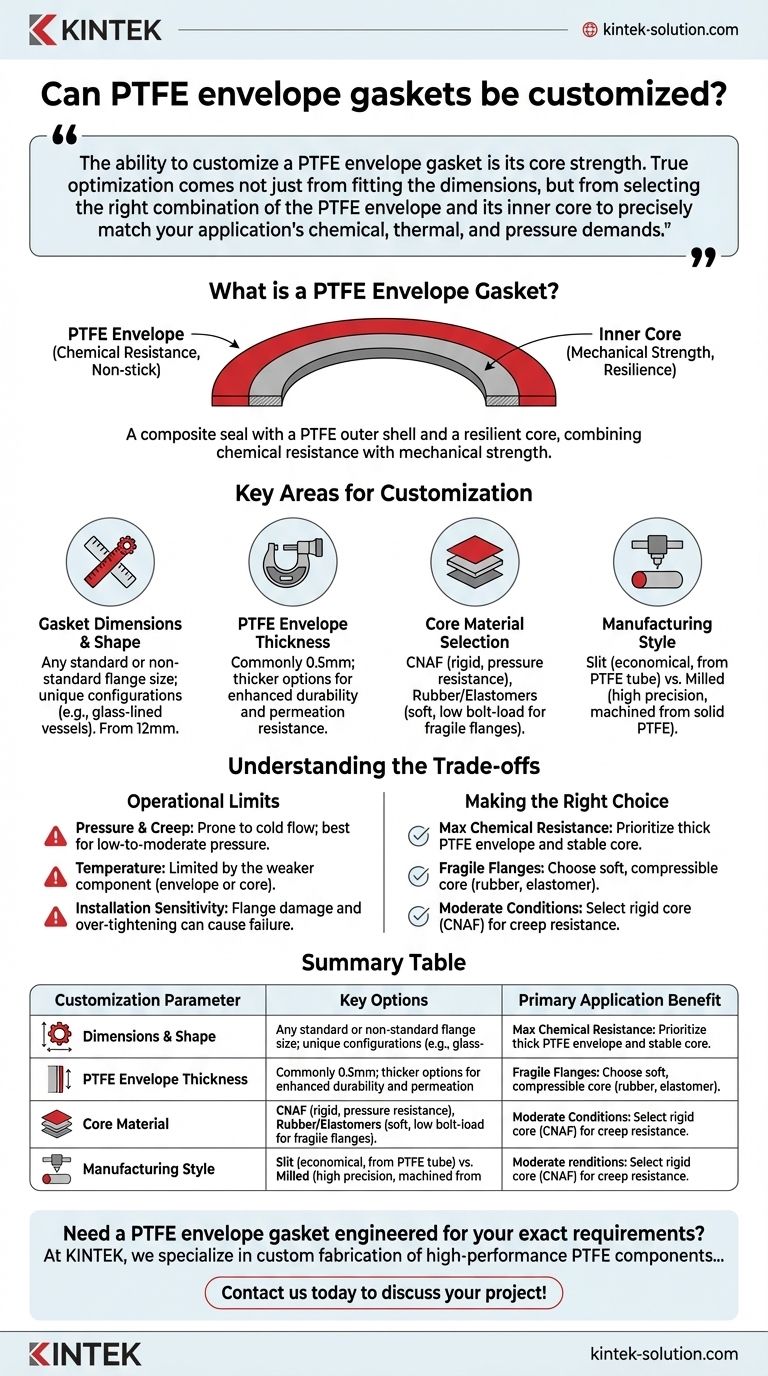

What is a PTFE Envelope Gasket?

A PTFE envelope gasket is a composite seal, not a monolithic one. Understanding its two-part construction is key to understanding its function and customization potential.

The Hybrid Construction

These gaskets consist of an outer "envelope" or jacket made of Polytetrafluoroethylene (PTFE). This shell encases a separate, more resilient core material.

This design cleverly combines the unparalleled chemical resistance of PTFE with the mechanical properties (like strength and compressibility) of the inner core material.

The Purpose of the Inner Core

The inner core provides the mechanical strength and resilience that pure PTFE lacks. Common core materials include compressed non-asbestos fiber (CNAF), rubber, and other elastomers.

The core material is what gives the gasket its ability to compress and create a tight seal under the pressure of a bolted flange.

The Role of the PTFE Envelope

The PTFE envelope's primary job is to protect the core material from the process media. PTFE is nearly inert, making it exceptionally resistant to corrosion from aggressive chemicals, acids, and solvents.

Its non-stick surface also prevents process material from adhering to the gasket, which simplifies cleaning and maintenance.

Key Areas for Customization

When you specify a custom PTFE envelope gasket, you are defining several critical parameters to match your operational needs.

Gasket Dimensions and Shape

This is the most common form of customization. Gaskets can be manufactured to fit any standard or non-standard flange size and shape, with dimensions starting as small as 12mm. This is especially critical for equipment like glass-lined vessels, which often have unique flange configurations.

PTFE Envelope Thickness

The thickness of the PTFE envelope itself can be specified, with 0.5mm being a common starting point. A thicker envelope can provide enhanced durability and permeation resistance for extremely aggressive or high-purity applications.

Core Material Selection

Choosing the right core is crucial. A soft rubber or elastomer core is ideal for fragile flanges (like glass or plastic) or uneven surfaces, as it can create a seal with lower bolt-load. A more rigid core, like CNAF, provides better resistance to pressure and creep (material flow under load).

Manufacturing Style: Milled vs. Slit

Gaskets are typically offered in two forms. Slit envelopes are formed from a tube of PTFE and are more economical. Milled envelopes are machined from a solid PTFE cylinder, offering greater dimensional precision for the most demanding applications.

Understanding the Trade-offs

While highly versatile, PTFE envelope gaskets have operational limits that must be respected.

Pressure and Creep Relaxation

PTFE is a relatively soft material prone to "creep" or cold flow under sustained pressure. While the inner core adds rigidity, these gaskets are best suited for low-to-moderate pressure applications. For very high pressures, a spiral wound or solid metal gasket may be more appropriate.

Temperature Limitations

The gasket's maximum operating temperature is determined by the weaker of its two components. A high-temperature PTFE envelope is of little use if the inner elastomer core will degrade or fail at that temperature. Always verify the temperature ratings for both the envelope and the core material.

Installation Sensitivity

The PTFE surface can be damaged by scratched or gouged flange faces. More importantly, over-tightening the flange bolts can crush the PTFE envelope or cause excessive creep, leading to seal failure. Adhering to proper torque specifications is critical for performance.

Making the Right Choice for Your Goal

When specifying a custom gasket, your primary application goal should guide your selections.

- If your primary focus is maximum chemical resistance: Prioritize a high-quality PTFE envelope of sufficient thickness and ensure the core material is stable at your operating temperature.

- If your primary focus is sealing fragile or uneven flanges: Choose a gasket with a more compressible core, such as rubber or a soft elastomer, which creates an effective seal at lower bolt loads.

- If your primary focus is managing moderate pressure and temperature: Select a rigid core material like compressed non-asbestos fiber (CNAF) to provide superior creep resistance and dimensional stability.

By carefully engineering these elements, you can create a sealing solution perfectly tailored to your system's unique challenges.

Summary Table:

| Customization Parameter | Key Options | Primary Application Benefit |

|---|---|---|

| Dimensions & Shape | Any size (from 12mm), standard or non-standard | Perfect fit for unique flanges, e.g., glass-lined vessels |

| PTFE Envelope Thickness | Common: 0.5mm; thicker options available | Enhanced durability and permeation resistance for aggressive media |

| Core Material | Compressed non-asbestos fiber (CNAF), rubber, elastomers | Optimized compressibility, strength, and creep resistance |

| Manufacturing Style | Slit (economical) or Milled (high precision) | Balance of cost-effectiveness and dimensional accuracy |

Need a PTFE envelope gasket engineered for your exact requirements?

At KINTEK, we specialize in custom fabrication of high-performance PTFE components, including seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your gasket is precisely tailored to handle your specific chemical, thermal, and pressure conditions—from prototypes to high-volume orders.

Contact us today to discuss your project and receive a solution that guarantees a reliable, long-lasting seal!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE oil seals? Superior Performance for Extreme Conditions

- Why is selecting the right PTFE packing important? Ensure Reliable Sealing & Prevent Costly Failures

- What are the temperature resistance properties of PTFE O-rings? Withstand -200°C to 260°C Extremes

- What is the purpose of sintering in the PTFE bush manufacturing process? | Achieve Superior Component Performance

- What are the considerations for managing PTFE's creep and thermal expansion? Ensure Dimensional Stability & Performance

- What is the cost-benefit analysis of using Teflon gland packing? Maximize ROI with Low-Cost Seals

- What types of parts can be fabricated using PTFE machining? Seals, Bushings, Insulators & More

- How do rubber gaskets compare to PTFE gaskets? Choose the Right Seal for Your Application