PTFE machining is used to fabricate a specific class of high-performance components where chemical resistance, low friction, and thermal stability are critical. This includes parts like seals, gaskets, bushings, bearings, and electrical insulators, which are frequently used in demanding automotive, aerospace, and chemical processing industries.

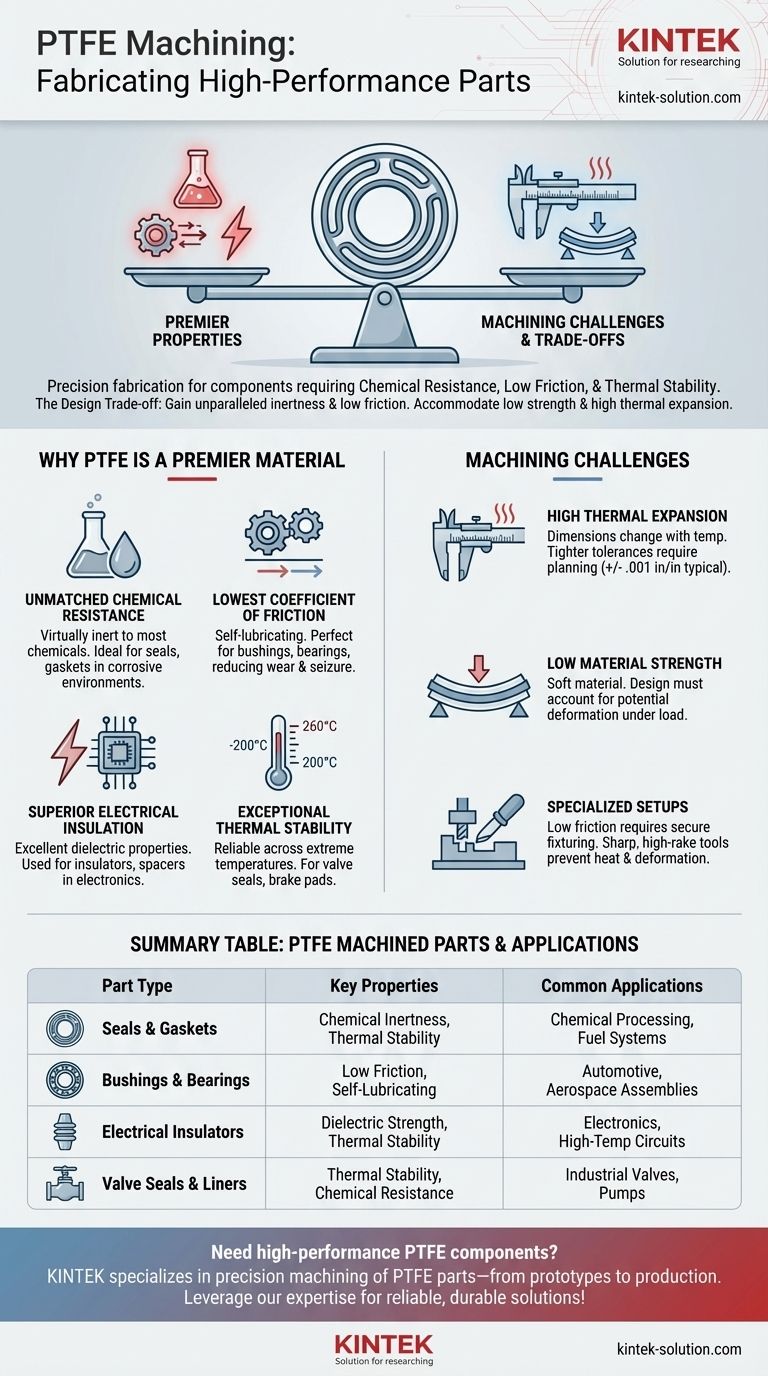

The decision to machine a part from PTFE is a direct trade-off. You gain its unparalleled chemical inertness and low-friction surface, but you must accommodate its low strength and high thermal expansion during the design and machining process.

Why PTFE is a Premier Material for Machined Parts

The unique properties of Polytetrafluoroethylene (PTFE) make it an ideal candidate for components that must survive extreme operational conditions. Unlike general-purpose plastics, PTFE offers a combination of attributes that are difficult to find in any other material.

Unmatched Chemical and Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals, solvents, and corrosive agents. This property makes it essential for creating durable seals, gaskets, and O-rings.

These components can maintain their integrity when exposed to aggressive fluids, ensuring leak-proof performance in fuel systems, chemical reactors, and hydraulic applications.

The Lowest Coefficient of Friction

With an exceptionally low coefficient of friction, PTFE is a self-lubricating material. This is why it is a top choice for parts that experience sliding contact.

Machined bushings, bearings, and shoulder washers made from PTFE reduce wear and prevent seizure in mechanical assemblies without the need for external lubricants.

Superior Electrical Insulation

PTFE possesses excellent dielectric properties, meaning it does not conduct electricity. This makes it a reliable material for manufacturing electrical insulators and spacers.

These components are used to isolate electrical circuits and prevent shorting in a wide range of temperatures, ensuring stability in sensitive electronics.

Exceptional Thermal Stability

PTFE parts can function reliably across an enormous temperature range, from -328°F to 500°F (-200°C to 260°C).

This stability allows components like valve seals and brake pads to perform consistently in high-stress automotive and aerospace environments where extreme temperature fluctuations are common.

Understanding the Trade-offs and Machining Challenges

While PTFE’s properties are highly desirable, they also introduce specific complexities into the fabrication process. An awareness of these challenges is crucial for successful part design.

Managing High Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning its dimensions can change significantly with temperature. This must be accounted for to achieve tight tolerances.

A general rule for machined PTFE is a tolerance of +/- .001 inches per inch of dimension, though reinforced grades can allow for tighter control.

Overcoming Low Material Strength

PTFE is a relatively soft material, which can lead to deformation or stress during machining if not handled correctly. This low strength requires careful planning.

The design must consider the material's limitations to ensure the final part possesses the necessary structural integrity for its application.

The Need for Specialized Setups

Because of its low friction, PTFE parts must be held securely in fixtures to prevent movement during machining.

Tooling is also critical. High-speed steel (HSS) or uncoated carbide tools with polished edges and high rake angles are recommended to minimize friction and heat generation, ensuring a clean and accurate cut.

How to Apply This to Your Project

Choosing to machine a part from PTFE depends entirely on the primary demands of your application.

- If your primary focus is sealing against harsh chemicals or fuels: PTFE is an exceptional choice for gaskets, seals, and fuel system components due to its near-total chemical inertness.

- If your primary focus is reducing friction and wear: Its self-lubricating properties make it ideal for bearings, bushings, and shoulder washers in mechanical systems.

- If your primary focus is electrical isolation in demanding environments: PTFE's high dielectric strength and thermal stability make it a reliable material for insulators and spacers.

Understanding these properties and their associated machining requirements is the key to successfully leveraging PTFE for your most critical components.

Summary Table:

| PTFE Machined Part Type | Key Properties Utilized | Common Applications |

|---|---|---|

| Seals & Gaskets | Chemical Inertness, Thermal Stability | Chemical Processing, Fuel Systems |

| Bushings & Bearings | Low Friction, Self-Lubricating | Automotive, Aerospace Assemblies |

| Electrical Insulators | Dielectric Strength, Thermal Stability | Electronics, High-Temperature Circuits |

| Valve Seals & Liners | Thermal Stability, Chemical Resistance | Industrial Valves, Pumps |

Need high-performance PTFE components for your project? KINTEK specializes in precision machining of PTFE parts—from custom prototypes to high-volume production. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring your components meet exact specifications for chemical resistance, low friction, and thermal stability. Contact us today to discuss your PTFE machining requirements and leverage our expertise for reliable, durable solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers