The fundamental purpose of sintering is to transform compressed Polytetrafluoroethylene (PTFE) powder into a single, solid piece. This critical heating process fuses the individual PTFE particles together, creating a durable and robust component with significantly improved mechanical properties.

Sintering is the essential manufacturing step that gives a PTFE bush its functional integrity. Without it, the component would simply be loosely packed powder, lacking the strength, durability, and wear resistance required for any practical application.

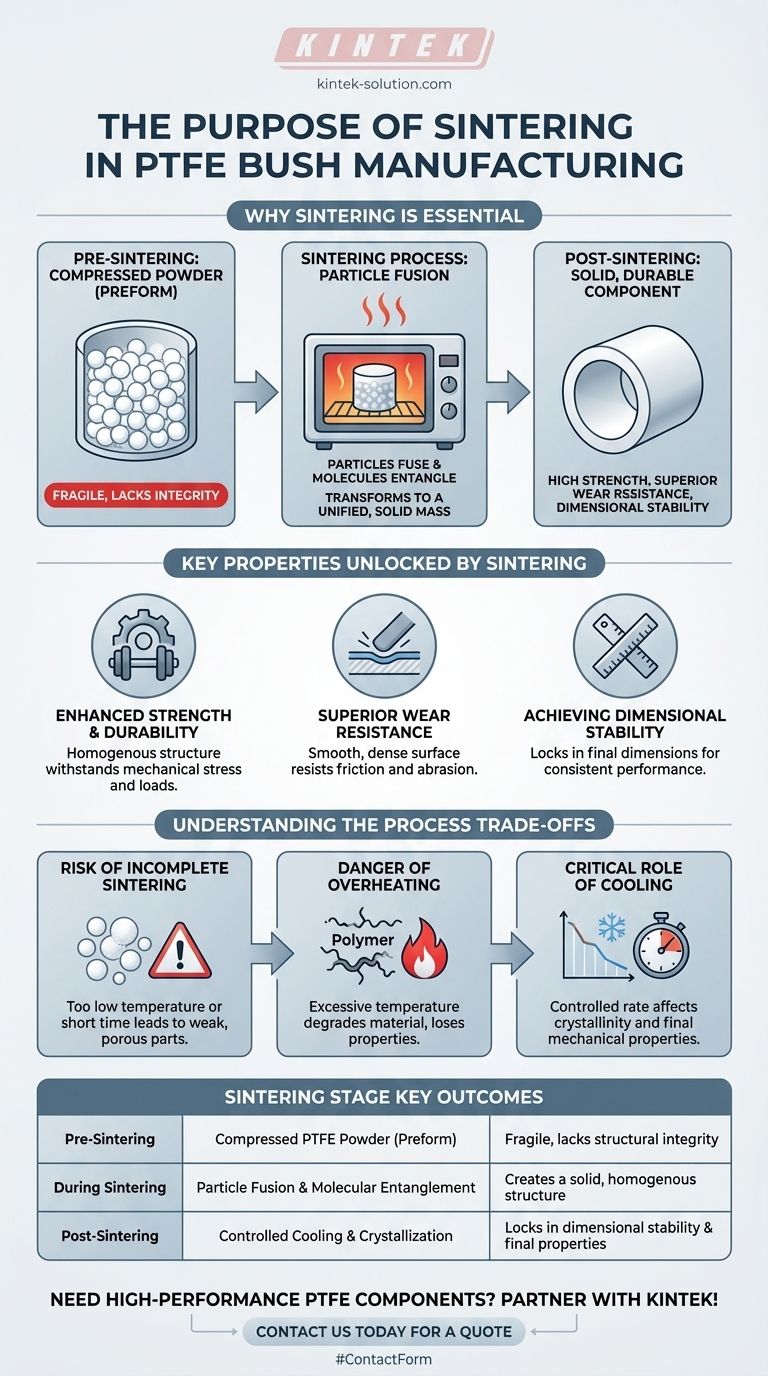

Why Sintering is a Non-Negotiable Step

To understand sintering, you must first understand the state of the material before this step. PTFE is not typically melt-processed like other plastics, so it starts as a powder that is compressed into a desired shape, known as a "preform."

From Loose Powder to a Solid Form

The preform is mechanically weak and has no structural integrity. It's merely a fragile shape held together by pressure.

Sintering provides the thermal energy necessary to fundamentally change this state. The process involves heating the PTFE preform in a carefully controlled oven to a temperature above its melting point.

The Particle Fusion Mechanism

At this elevated temperature, the individual PTFE particles do not liquefy but instead fuse together at their boundaries. The long-chain molecules of the polymer entangle and interlock, creating a unified, solid mass.

This molecular entanglement is the source of the final component's strength and resilience.

Key Properties Unlocked by Sintering

The sintering process is directly responsible for creating the high-performance characteristics that PTFE is known for. It is not just about making the part solid; it's about making it useful.

Enhanced Strength and Durability

The fusion of particles creates a homogenous structure that can withstand mechanical stress and loads. This transforms the fragile preform into a tough, durable part suitable for industrial use.

Superior Wear Resistance

A properly sintered PTFE bush has a smooth, dense surface. This structure is highly resistant to friction and abrasion, which is a critical requirement for a bushing component that is, by definition, a type of bearing.

Achieving Dimensional Stability

The heating and subsequent controlled cooling process locks in the final dimensions of the bush. This ensures the component will maintain its shape and tolerances during operation.

Understanding the Process Trade-offs

While essential, the sintering process is not without its challenges. The final quality of the PTFE bush is highly dependent on precise control over the heating and cooling cycle.

The Risk of Incomplete Sintering

If the temperature is too low or the heating time is too short, the particles will not fuse completely. This results in a mechanically weak and porous part that will fail prematurely in its application.

The Danger of Overheating

Conversely, excessive temperatures can degrade the PTFE polymer. This can cause discoloration and a loss of the material's desirable properties, such as its chemical resistance and low-friction surface.

The Critical Role of Cooling

The rate at which the PTFE bush is cooled after sintering directly influences its crystallinity. This, in turn, affects its final mechanical properties, including hardness and tensile strength, requiring precise control to meet application specifications.

Applying This to Your Goal

The importance of sintering becomes clear when you consider the final application of the PTFE bush.

- If your primary focus is high-load capacity: Proper sintering is non-negotiable, as it directly creates the mechanical strength required to prevent the bush from deforming or failing.

- If your primary focus is longevity in a high-wear environment: The dense, fused surface created by sintering provides the superior wear resistance needed for a long service life.

- If your primary focus is precision engineering: The controlled sintering and cooling cycle is essential for achieving the dimensional stability required for a reliable fit and consistent performance.

Ultimately, sintering is the crucial step that unlocks the inherent potential of the PTFE material, turning it into a high-performance engineering component.

Summary Table:

| Sintering Stage | Key Outcome | Impact on PTFE Bush |

|---|---|---|

| Pre-Sintering | Compressed PTFE Powder (Preform) | Fragile, lacks structural integrity |

| During Sintering | Particle Fusion & Molecular Entanglement | Creates a solid, homogenous structure |

| Post-Sintering | Controlled Cooling & Crystallization | Locks in dimensional stability and final mechanical properties |

| Final Result | Dense, Unified Component | High strength, superior wear resistance, and reliable performance |

Need High-Performance PTFE Components? Partner with KINTEK!

Your PTFE bush's performance is only as good as its manufacturing process. At KINTEK, we specialize in the precise sintering and custom fabrication of PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure every part achieves the superior strength, durability, and dimensional accuracy your application demands.

Let us bring your project to life, from prototypes to high-volume orders.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability