At its core, the cost-benefit analysis of Teflon (PTFE) gland packing is straightforward. While it commands a higher initial purchase price than many traditional packing materials, its total cost of ownership is significantly lower due to superior longevity, reduced maintenance demands, and prevention of costly operational downtime.

The decision to use Teflon gland packing is an investment in operational reliability. You are trading a higher upfront material cost for a substantial long-term reduction in labor, equipment wear, and lost production time.

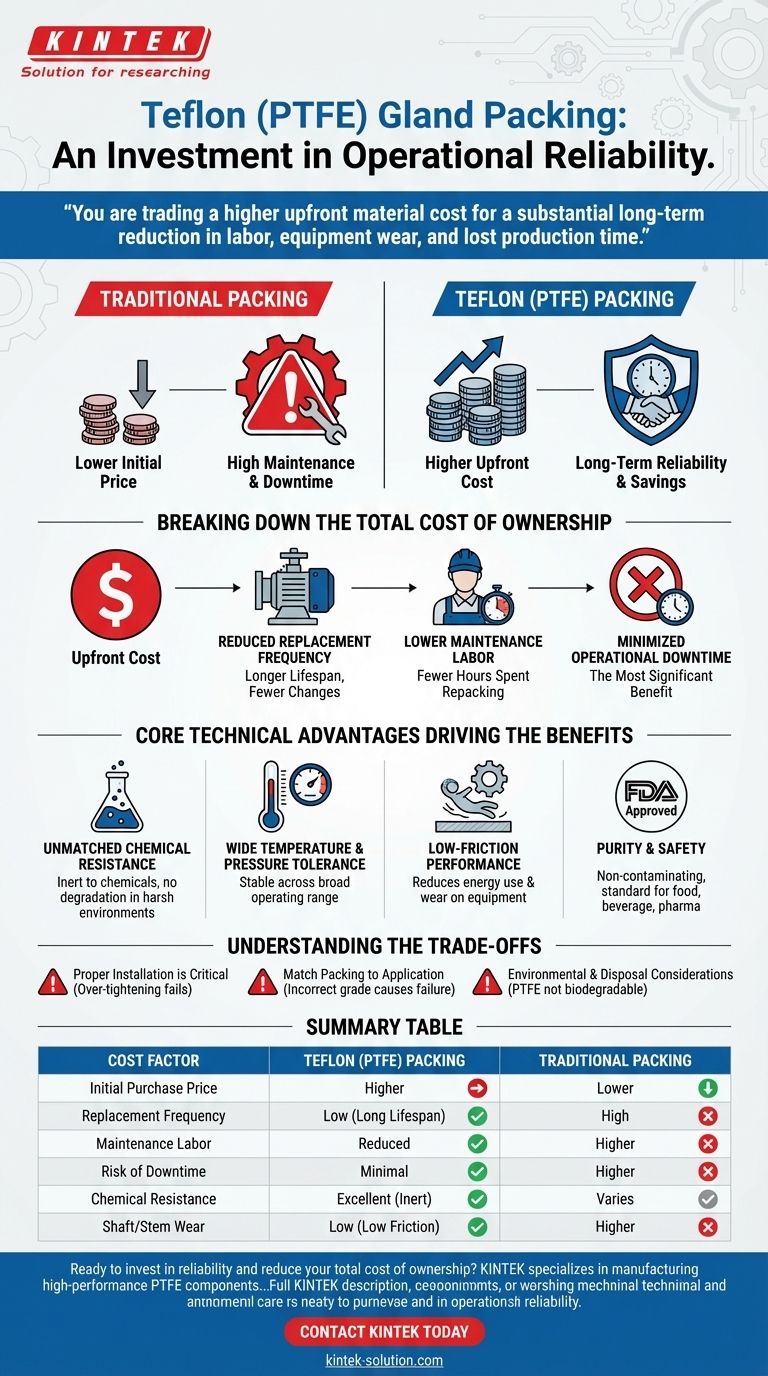

Breaking Down the Total Cost of Ownership

The true financial impact of a sealing solution extends far beyond its price tag. The value of Teflon packing becomes clear when you analyze the full lifecycle cost.

The Upfront Cost: The Initial Hurdle

The purchase price of Teflon packing is undeniably higher than materials like graphite or vegetable fiber alternatives. This initial outlay is the primary "cost" in the cost-benefit equation.

However, this cost should not be evaluated in isolation. It is the entry point for accessing a higher tier of performance and reliability.

The Return on Investment: Where Savings Accumulate

The long-term savings generated by Teflon packing are substantial and come from several key areas.

- Reduced Replacement Frequency: Teflon's durability means it lasts significantly longer, reducing the number of times packing needs to be replaced over the equipment's lifespan.

- Lower Maintenance Labor: Fewer replacements directly translate to fewer hours spent by maintenance personnel on repacking pumps and valves.

- Minimized Operational Downtime: This is the most significant financial benefit. Unplanned downtime to fix a leaking seal can cost thousands of dollars per hour in lost production, making a reliable seal an invaluable asset.

Core Technical Advantages Driving the Benefits

The economic advantages of Teflon packing are a direct result of its superior material properties. Understanding these technical merits is key to justifying the investment.

Unmatched Chemical Resistance

Teflon is chemically inert across the entire pH scale. It will not degrade or swell when exposed to aggressive chemicals, ensuring a reliable seal in harsh processing environments found in the chemical, oil, and gas industries.

Wide Temperature and Pressure Tolerance

This packing maintains its integrity and sealing capability across a broad range of operating temperatures and pressures. This stability prevents seal failure when operational conditions fluctuate.

Low-Friction Performance

Teflon has an extremely low coefficient of friction. This reduces the energy required to operate the equipment and, more importantly, minimizes wear on the pump shaft or valve stem, extending the life of these critical and expensive components.

Purity and Safety

Because it is chemically inert and non-reactive, Teflon packing is a standard in the food, beverage, and pharmaceutical industries. It does not contaminate the processed media, ensuring product purity and compliance.

Understanding the Trade-offs and Risks

An objective analysis requires acknowledging potential downsides and operational requirements. The benefits of Teflon packing are not automatic; they depend on proper application.

The Critical Role of Proper Installation

The performance of Teflon packing is highly dependent on correct installation. Mistakes can easily negate its benefits.

Key failure points include over-tightening the gland follower, which prevents necessary leakage for lubrication, or failing to thoroughly clean the stuffing box before installation.

Matching the Packing to the Application

Not all Teflon packing is the same. It is crucial to select the correct grade and construction based on the specific equipment, operating pressure, temperature, and media being sealed. A mismatch can lead to premature failure.

Environmental and Disposal Considerations

PTFE is not biodegradable, so used packing material requires proper disposal according to local regulations. This is a minor but important consideration in the product's lifecycle management.

Making the Right Choice for Your Operation

To determine if Teflon gland packing is the right choice, align the investment with your primary operational goals.

- If your primary focus is minimizing upfront capital expenditure: Be prepared for more frequent maintenance cycles and the potential for higher downtime costs associated with lower-cost alternatives.

- If your primary focus is reducing operational downtime and labor costs: Teflon packing is the superior choice, as its longevity directly translates to higher plant availability and reduced maintenance overhead.

- If you are operating in harsh chemical or high-temperature environments: The chemical resistance and thermal stability of Teflon are non-negotiable for ensuring operational safety and seal integrity.

- If you are in a food, beverage, or pharmaceutical industry: Teflon's inert nature is essential for maintaining product purity and meeting regulatory compliance standards.

Ultimately, choosing Teflon gland packing is an investment in operational stability and the long-term health of your critical equipment.

Summary Table:

| Cost Factor | Teflon (PTFE) Packing | Traditional Packing |

|---|---|---|

| Initial Purchase Price | Higher | Lower |

| Replacement Frequency | Low (Long Lifespan) | High |

| Maintenance Labor | Reduced | Higher |

| Risk of Downtime | Minimal | Higher |

| Chemical Resistance | Excellent (Inert) | Varies |

| Shaft/Stem Wear | Low (Low Friction) | Higher |

Ready to invest in reliability and reduce your total cost of ownership?

KINTEK specializes in manufacturing high-performance PTFE components, including custom gland packing for the semiconductor, medical, laboratory, and industrial sectors. Our precision-engineered seals are designed to extend equipment life, minimize downtime, and withstand harsh chemical environments.

Whether you need a prototype or a high-volume order, we deliver solutions that protect your bottom line.

Contact KINTEK today for a consultation on the right sealing solution for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications