Yes, Teflon sheets are designed for repeated use. Their durability stems from the inherent properties of PTFE (Polytetrafluoroethylene), which is highly resistant to heat, abrasion, and chemicals. This allows you to clean and reuse a single sheet for multiple projects, making them a cost-effective tool in processes like heat pressing and food preparation.

While Teflon sheets are highly reusable, their effective lifespan is not infinite. Maximizing their value depends on proper handling and regular inspection, as signs of wear can directly compromise the quality of your work.

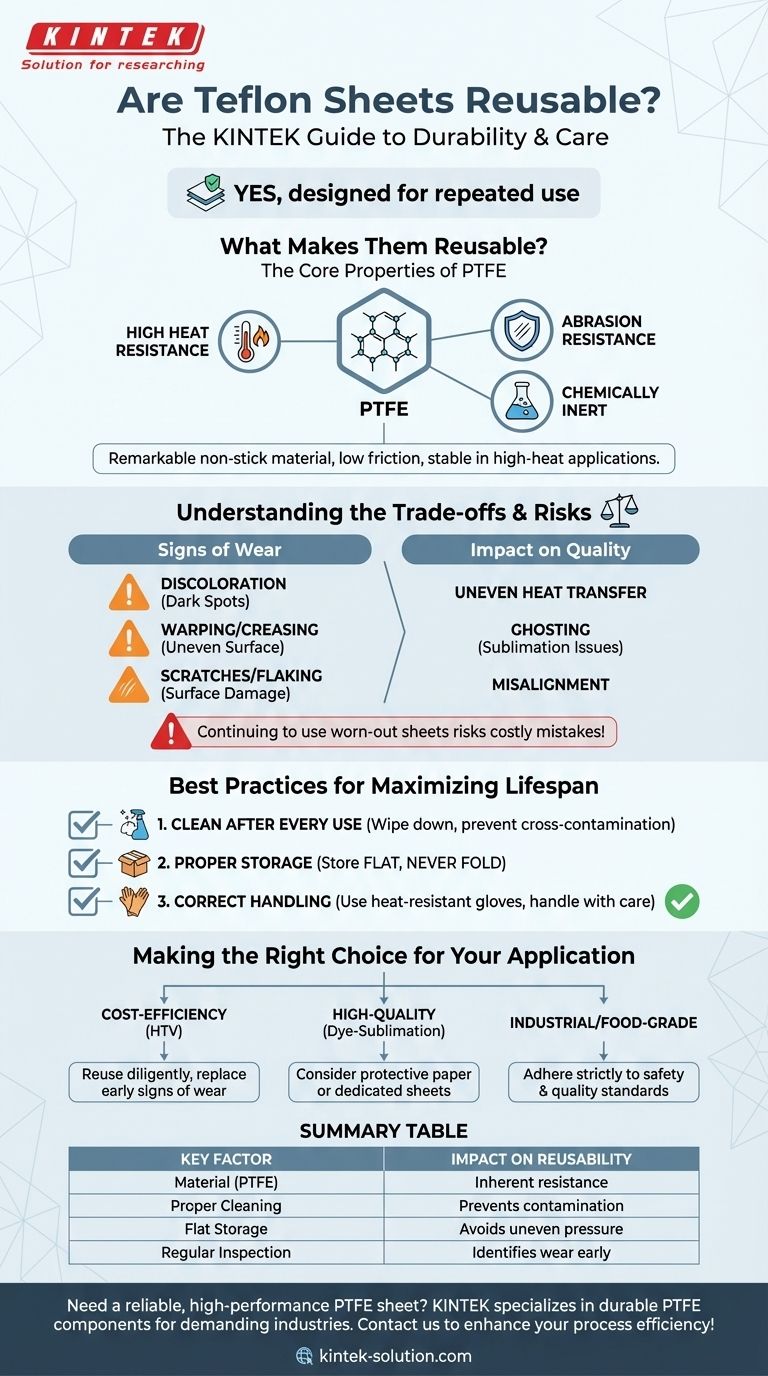

What Makes Teflon Sheets Reusable?

The reusability of a Teflon sheet is not a feature added after the fact; it is a direct result of the material's fundamental chemistry and physical properties. Understanding this foundation helps you use them more effectively.

The Core Properties of PTFE

The active material in a Teflon sheet is Polytetrafluoroethylene (PTFE). This fluoropolymer is known for its remarkable characteristics, including an extremely low coefficient of friction, making it one of the most non-stick materials known.

PTFE is also chemically inert and boasts a very high melting point, which is why it excels in high-heat applications. These properties ensure the sheet does not easily degrade, react with your materials, or stick to your projects.

Durability in Practice

In a practical setting, these properties translate to high heat and abrasion resistance. A Teflon sheet can withstand the repeated cycles of a heat press or the demands of an industrial process without quickly breaking down, losing its non-stick surface, or transferring unwanted residue.

Understanding the Trade-offs and Risks of Reuse

Reusing a Teflon sheet is a balance between economy and quality. While durable, these sheets are consumable tools that eventually wear out. Ignoring the signs of degradation can lead to costly mistakes.

When to Replace Your Sheet

Inspect your sheet before every use. It is time for a replacement if you notice:

- Discoloration or Scorching: Darkened spots can indicate uneven heat transfer.

- Warping or Creasing: A sheet that no longer lies perfectly flat can cause inconsistent pressure and crooked transfers.

- Scratches or Flaking: Any damage to the surface compromises its non-stick properties and can trap debris or dyes.

Impact on Project Quality

Continuing to use a worn-out sheet introduces significant risks. The most common issues are related to heat transfer applications like dye-sublimation or heat-transfer vinyl (HTV).

A worn sheet may absorb and retain heat unevenly, leading to inconsistent results. It can also contribute to "ghosting" in sublimation, where faint images from previous presses are transferred to a new item. Finally, a warped or improperly placed sheet can move during pressing, ruining the alignment of your design.

Best Practices for Maximizing Lifespan

Proper care is the key to getting the most value from your Teflon sheets. A few simple habits can dramatically extend their functional life.

Clean After Every Use

Wipe the sheet down with a soft cloth after it has cooled. For more stubborn residue, a damp cloth is usually sufficient. This prevents cross-contamination of colors or materials between projects.

Proper Storage is Critical

Store your sheets flat or loosely rolled. Never fold a Teflon sheet, as this will create permanent creases that interfere with even pressure distribution.

Correct Handling During Use

Always ensure the sheet is large enough to cover your entire design and that it lies perfectly flat on the heat press. When handling a hot sheet, use heat-resistant gloves to protect yourself and avoid accidentally creasing the material.

Making the Right Choice for Your Application

How you approach reusability should depend on your specific goal and tolerance for risk.

- If your primary focus is cost-efficiency for basic HTV projects: Reuse your sheets diligently, but replace them at the first sign of wear to avoid wasting vinyl on a failed press.

- If your primary focus is high-quality dye-sublimation: Consider using protective paper or a dedicated sheet for critical projects, as even a clean Teflon sheet can sometimes contribute to ghosting issues.

- If your primary focus is industrial or food-grade applications: Adhere strictly to your industry's safety and quality standards, which may dictate a specific replacement schedule regardless of visible wear.

By treating your Teflon sheet as a valuable tool rather than a disposable accessory, you maximize both its lifespan and the quality of your work.

Summary Table:

| Key Factor | Impact on Reusability |

|---|---|

| Material (PTFE) | Provides inherent heat, chemical, and abrasion resistance for multiple uses. |

| Proper Cleaning | Prevents cross-contamination and maintains the non-stick surface. |

| Flat Storage | Avoids permanent creases that cause uneven pressure. |

| Regular Inspection | Identifies wear (scratches, warping, discoloration) before it ruins a project. |

Need a reliable, high-performance PTFE sheet for your application?

KINTEK specializes in manufacturing durable PTFE components, including reusable sheets, seals, and liners, for demanding industries like semiconductor, medical, and laboratory use. Our commitment to precision ensures consistent quality and performance, whether you need a standard product or a custom-fabricated solution from prototype to high-volume orders.

Contact KINTEK today to discuss how our PTFE sheets can enhance your process efficiency and project quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Do PTFE backups provide chemical resistance to rubber O-rings? The Surprising Truth About Seal Protection

- How is PTFE used in the aerospace industry? Ensuring Reliability in Extreme Conditions

- What are the advantages of glass-filled PTFE? Enhance Strength, Wear, and Creep Resistance

- How does Teflon coating improve efficiency in food production? Reduce Downtime and Boost Yields

- What are the benefits of using PTFE liners in medical procedures? Enhance Safety & Performance

- What are the properties of stainless steel-reinforced PTFE? A High-Performance Composite for Demanding Seals

- What are PTFE rotary lip seals and what applications are they used for? High-Performance Sealing Solutions

- What are the main differences between RPTFE and standard PTFE for valve seats? Choose the Right Material for Your System