At its core, Teflon coating improves efficiency in food production by creating an exceptionally non-stick, heat-resistant, and chemically inert surface. This single intervention dramatically reduces equipment cleaning downtime, minimizes product waste from sticking, and protects machinery from corrosion, enabling a more continuous and profitable operation.

The central challenge in food processing is managing adhesion and friction. Teflon's unique properties directly counteract these forces, transforming production bottlenecks into seamless, continuous workflows and ensuring higher product quality and yield.

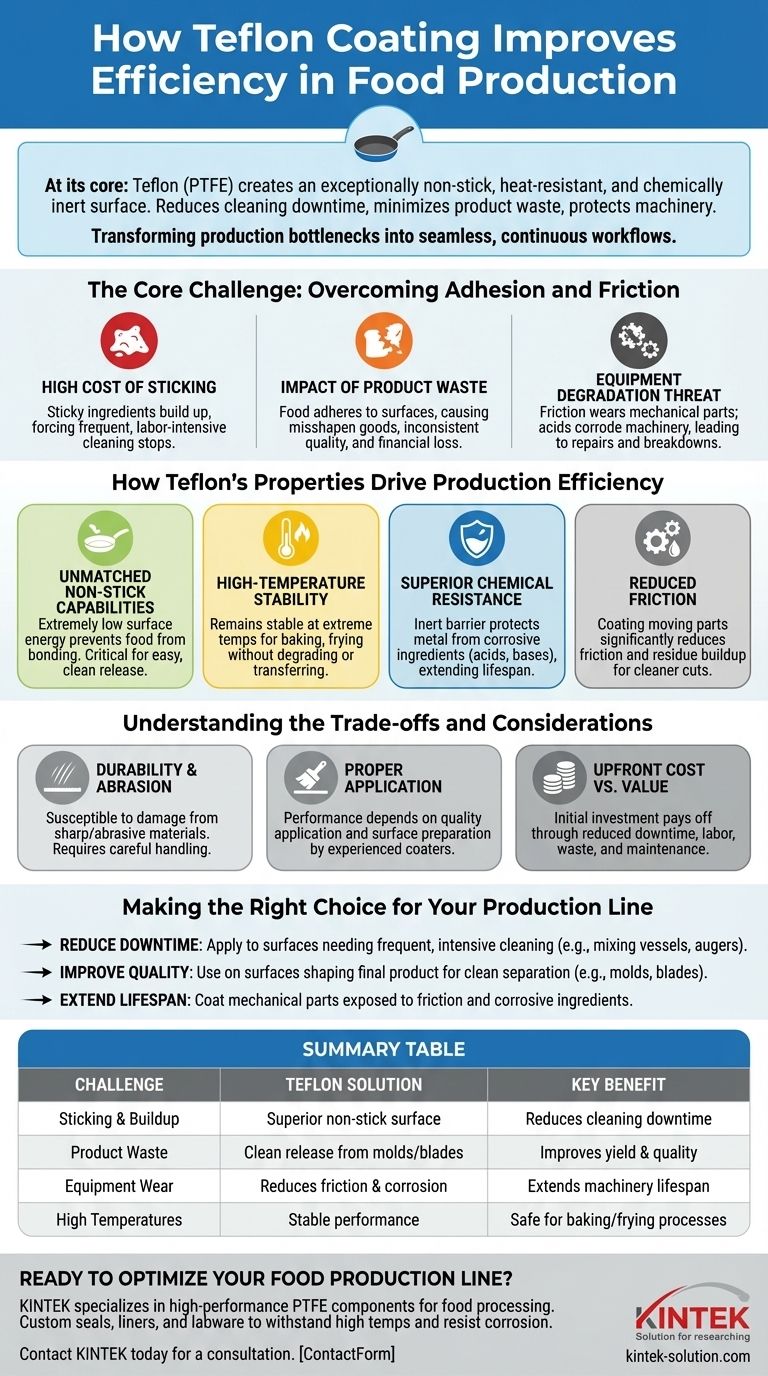

The Core Challenge: Overcoming Adhesion and Friction

In any food production environment, the physical properties of the ingredients themselves present the greatest operational hurdles. Overcoming these is the key to efficiency.

The High Cost of Sticking

Sticky ingredients like sugar, cheese, and dough are notorious for building up on equipment surfaces.

This buildup forces production lines to a halt for frequent and often labor-intensive cleaning, directly translating to lost production time and increased labor costs.

The Impact of Product Waste

When food adheres to molds, trays, cutting blades, or conveyor belts, it often becomes misshapen or damaged.

This leads to lower product yields, inconsistent quality, and direct financial loss from discarded goods that do not meet standards.

The Threat of Equipment Degradation

Constant friction from moving ingredients wears down mechanical parts, while acidic or alkaline foods can corrode expensive machinery.

This degradation leads to costly repairs, premature equipment replacement, and unexpected breakdowns that can cripple a production line.

How Teflon's Properties Drive Production Efficiency

Teflon (PTFE) coating provides a multi-faceted solution to the core challenges of adhesion, heat, and corrosion. Its distinct characteristics translate directly into measurable operational gains.

Unmatched Non-Stick and Release Capabilities

Teflon's primary benefit is its extremely low surface energy, which creates a superior non-stick surface. Food simply does not bond to it.

This "release" property is critical for applications like sugar cube molds, waffle irons, and cheese augers, allowing for easy, clean removal of the product and drastically reducing cleaning time between batches.

High-Temperature Stability

Food processing often involves extreme temperatures for baking, frying, or molding.

Teflon coatings remain stable at these high temperatures without degrading or transferring any substances to the food. This makes them ideal for lining baking sheets, conveyor belts, and commercial frying pans.

Superior Chemical and Corrosion Resistance

The coating creates an inert barrier that protects the underlying metal from corrosive ingredients like acids and bases.

This property is vital for extending the lifespan of machinery, preventing rust, and ensuring the integrity of the equipment over thousands of hours of operation.

Reduced Friction for Mechanical Parts

Coating moving parts, such as the cutting knives used for potato chips or the piano wires for slicing cookie dough, significantly reduces friction and residue buildup.

This results in cleaner, more uniform cuts, less strain on motors and mechanical systems, and less frequent need for sharpening or replacement.

Understanding the Trade-offs and Considerations

While highly effective, Teflon coating is not a universal solution. Acknowledging its limitations is key to using it effectively.

Durability and Abrasion Resistance

Teflon coatings can be damaged by sharp utensils or highly abrasive materials. They are a surface layer, not a core property of the metal.

This means that coated parts require careful handling and may need periodic re-coating, which should be factored into maintenance schedules and budgets.

The Importance of Proper Application

The performance of a Teflon coating is entirely dependent on the quality of its application. This requires specialized surface preparation and curing processes.

Choosing an experienced industrial coater is critical to ensure proper adhesion and achieve the desired durability and performance.

Upfront Cost vs. Long-Term Value

There is an initial investment required to have equipment professionally coated.

The return on this investment is realized over time through significant reductions in downtime, labor for cleaning, product waste, and maintenance costs.

Making the Right Choice for Your Production Line

Applying Teflon strategically targets your most significant points of inefficiency.

- If your primary focus is reducing downtime: Apply Teflon to surfaces that require the most frequent and intensive cleaning, such as mixing vessels, molds, and augers.

- If your primary focus is improving product quality: Use Teflon on surfaces that shape the final product, like cutting blades and molds, to ensure clean separation and perfect, uniform results.

- If your primary focus is extending equipment lifespan: Coat mechanical parts and surfaces exposed to corrosive ingredients to create a durable barrier against friction, wear, and chemical damage.

Ultimately, integrating Teflon coating is a strategic investment in operational continuity and a more efficient, profitable production process.

Summary Table:

| Challenge | How Teflon Coating Helps | Key Benefit |

|---|---|---|

| Sticking & Buildup | Superior non-stick surface | Reduces cleaning downtime |

| Product Waste | Clean release from molds/blades | Improves yield & quality |

| Equipment Wear | Reduces friction & corrosion | Extends machinery lifespan |

| High Temperatures | Stable performance | Safe for baking/frying processes |

Ready to optimize your food production line?

At KINTEK, we specialize in manufacturing high-performance PTFE (Teflon) components—including custom seals, liners, and labware—specifically for the demanding environments of the food processing industry. Our precision coatings are engineered to withstand high temperatures, resist corrosive ingredients, and provide the ultimate non-stick surface, directly addressing your biggest challenges of downtime, waste, and equipment wear.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your unique application. Let us help you achieve a more continuous, efficient, and profitable operation.

Contact KINTEK today for a consultation and see how our PTFE solutions can transform your process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support