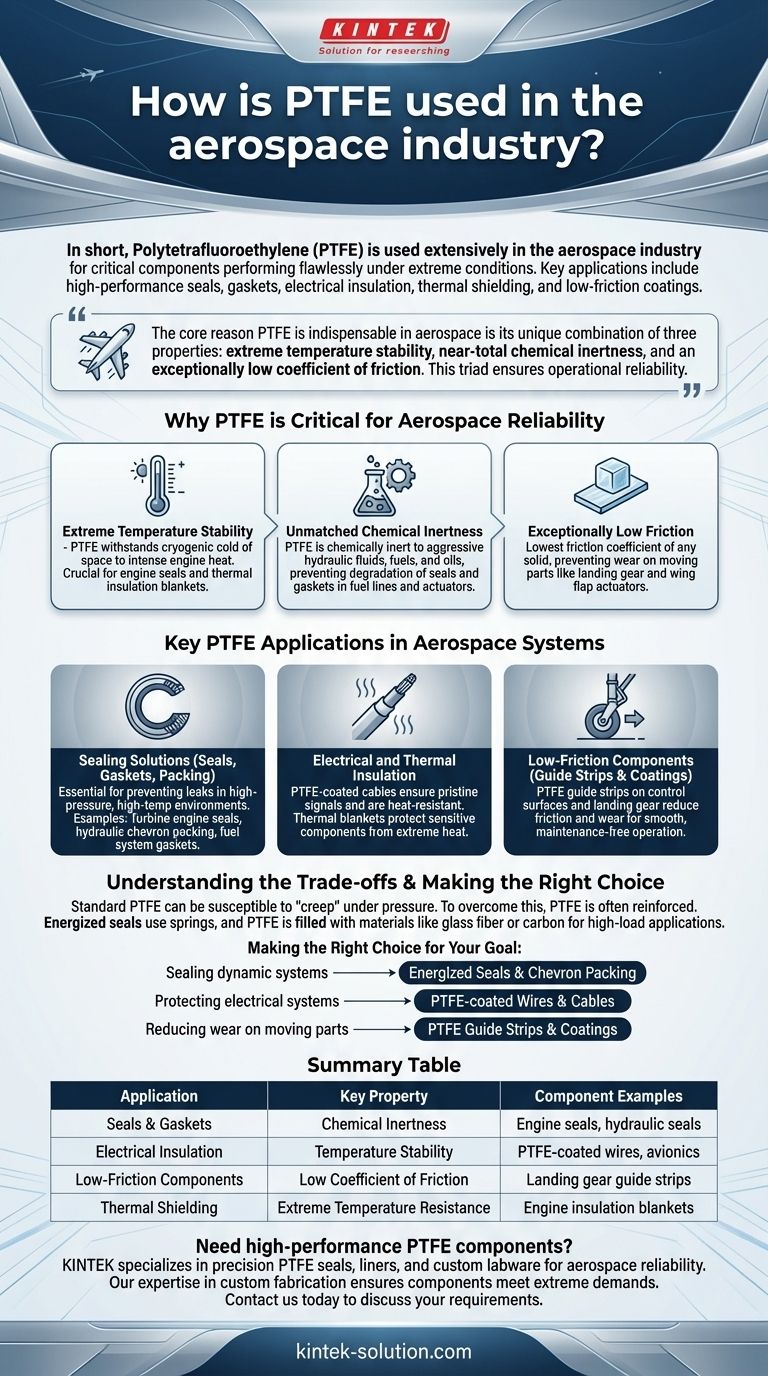

In short, Polytetrafluoroethylene (PTFE) is used extensively in the aerospace industry for critical components that must perform flawlessly under extreme conditions. Its primary applications include high-performance seals, gaskets, electrical wire insulation, thermal shielding, and low-friction coatings on moving parts like landing gear and control surfaces. These components are essential for the reliability of everything from hydraulic systems and engines to flight controls.

The core reason PTFE is indispensable in aerospace is its unique combination of three properties: extreme temperature stability, near-total chemical inertness, and an exceptionally low coefficient of friction. This triad ensures operational reliability where failure is not an option.

Why PTFE is Critical for Aerospace Reliability

The aerospace environment is one of the most demanding imaginable, subjecting materials to a brutal range of temperatures, pressures, and corrosive substances. PTFE's molecular structure gives it a unique resilience that standard materials cannot match.

Extreme Temperature Stability

PTFE maintains its integrity across an exceptionally wide temperature spectrum. It can withstand the cryogenic cold of high altitudes and space as well as the intense heat generated by aircraft engines and atmospheric reentry friction.

This stability is crucial for components like engine seals and thermal insulation blankets that must function consistently without becoming brittle or degrading.

Unmatched Chemical Inertness

Aerospace systems rely on aggressive hydraulic fluids, fuels, and oils. PTFE is chemically inert, meaning it does not react with these corrosive substances.

This property prevents the degradation of seals and gaskets in critical systems like fuel lines, actuators, and gearboxes, ensuring they don't leak or fail over time.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is vital for preventing wear and tear on moving parts.

In applications like landing gear and wing flap actuators, this low-friction characteristic reduces mechanical stress and prevents debris from building up, which could otherwise lead to system seizure.

Key PTFE Applications in Aerospace Systems

PTFE is not a single solution but is engineered into various forms to solve specific challenges across an aircraft.

Sealing Solutions (Seals, Gaskets, Packing)

This is arguably the most common use of PTFE in aerospace. PTFE seals are essential for preventing leaks in high-pressure and high-temperature environments.

Specific applications include seals for turbine engines, actuators, landing gear, fuel systems, auxiliary power units (APUs), and cryogenic valves. Specialized designs like PTFE lip seals and chevron packing are used in hydraulic systems to ensure consistent performance under immense pressure.

Electrical and Thermal Insulation

The reliability of an aircraft's communication and control systems depends on pristine electrical signals. PTFE-coated cables and wires provide superior insulation that is lightweight, heat-resistant, and chemically inert.

Its thermal properties also make it an ideal material for thermal insulation blankets and shields, protecting sensitive components from the extreme heat of engines and exhaust systems.

Low-Friction Components (Guide Strips & Coatings)

To ensure smooth and reliable movement, PTFE is applied to surfaces that experience high stress. PTFE guide strips are used in components like control surfaces and landing gear.

These strips act as a buffer, reducing friction and wear between moving metal parts and ensuring they operate smoothly throughout thousands of cycles without maintenance.

Understanding the Trade-offs

While its properties are exceptional, it's important to understand that standard PTFE is a relatively soft material. In its pure form, it can be susceptible to "creep" or cold flow under sustained pressure.

The Need for Reinforcement

To overcome this limitation for high-load applications, PTFE is often enhanced. Energized seals, for instance, incorporate a spring to provide a constant force, improving sealing performance and resilience.

Similarly, PTFE can be filled with other materials like glass fiber, carbon, or bronze to increase its strength, dimensional stability, and abrasion resistance for the most demanding environments, such as in external gearbox seals or rotorheads.

Making the Right Choice for Your Goal

The specific form of PTFE used is dictated by the engineering challenge at hand.

- If your primary focus is sealing dynamic systems under high pressure: Look to specialized designs like PTFE chevron packing or energized seals, which offer superior strength and durability.

- If your primary focus is protecting electrical systems: PTFE-coated wires and cables provide the highest level of thermal and chemical resistance for critical avionics.

- If your primary focus is reducing wear on moving mechanical parts: PTFE guide strips and coatings are the definitive choice for creating a durable, low-friction surface.

Ultimately, PTFE's versatility and unparalleled performance in harsh environments make it a foundational material for modern aerospace engineering.

Summary Table:

| Application | Key Property | Component Examples |

|---|---|---|

| Seals & Gaskets | Chemical Inertness | Engine seals, hydraulic system seals, fuel line gaskets |

| Electrical Insulation | Temperature Stability | PTFE-coated wires, avionics insulation |

| Low-Friction Components | Low Coefficient of Friction | Landing gear guide strips, control surface coatings |

| Thermal Shielding | Extreme Temperature Resistance | Engine insulation blankets, heat shields |

Need high-performance PTFE components for your aerospace applications? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that meet the extreme demands of aerospace reliability. Contact us today to discuss your specific requirements and leverage our material science expertise for your critical systems.

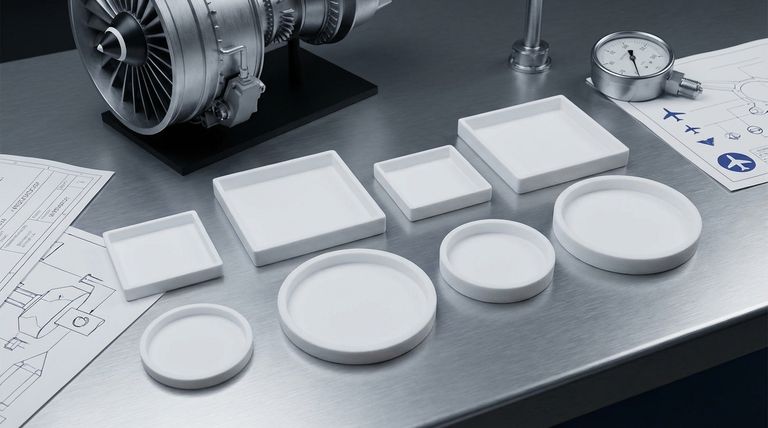

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- In what scenarios are PTFE bellows not the best choice? Avoid System Failure by Understanding PTFE's Limits

- What are the electrical properties of PTFE? Discover Unmatched Insulation Performance

- What are the durability and reusability benefits of Teflon sheets? Achieve Consistent, Cost-Effective Performance

- What types of chemical substances can PTFE bushings withstand? Ensure Reliability in Aggressive Environments

- What long-term business benefits can PTFE diaphragm valves provide to pharmaceutical companies? Boost Yield & Cut Costs

- What are dynamic applications and why are PTFE O-Rings suitable for them? Unlock Low-Friction, Chemical-Resistant Sealing

- What benefits does PTFE provide in athletic footwear? Enhancing Performance with Low-Friction & Non-Stick Solutions

- What are the benefits of PTFE-encapsulated O-rings? Superior Sealing for Harsh Chemical & High-Temp Environments