At their core, PTFE rotary lip seals are high-performance sealing components designed specifically for dynamic, rotating shafts. Made from Polytetrafluoroethylene (PTFE), they are engineered to prevent fluid leakage and contamination in challenging industrial, automotive, and aerospace applications where traditional rubber seals would quickly fail due to high speeds, aggressive chemicals, or extreme temperatures.

The critical takeaway is that PTFE rotary lip seals are not general-purpose parts; they are specialized problem-solvers. You choose them when the operational demands of speed, temperature, or chemical exposure exceed the capabilities of conventional elastomeric seals.

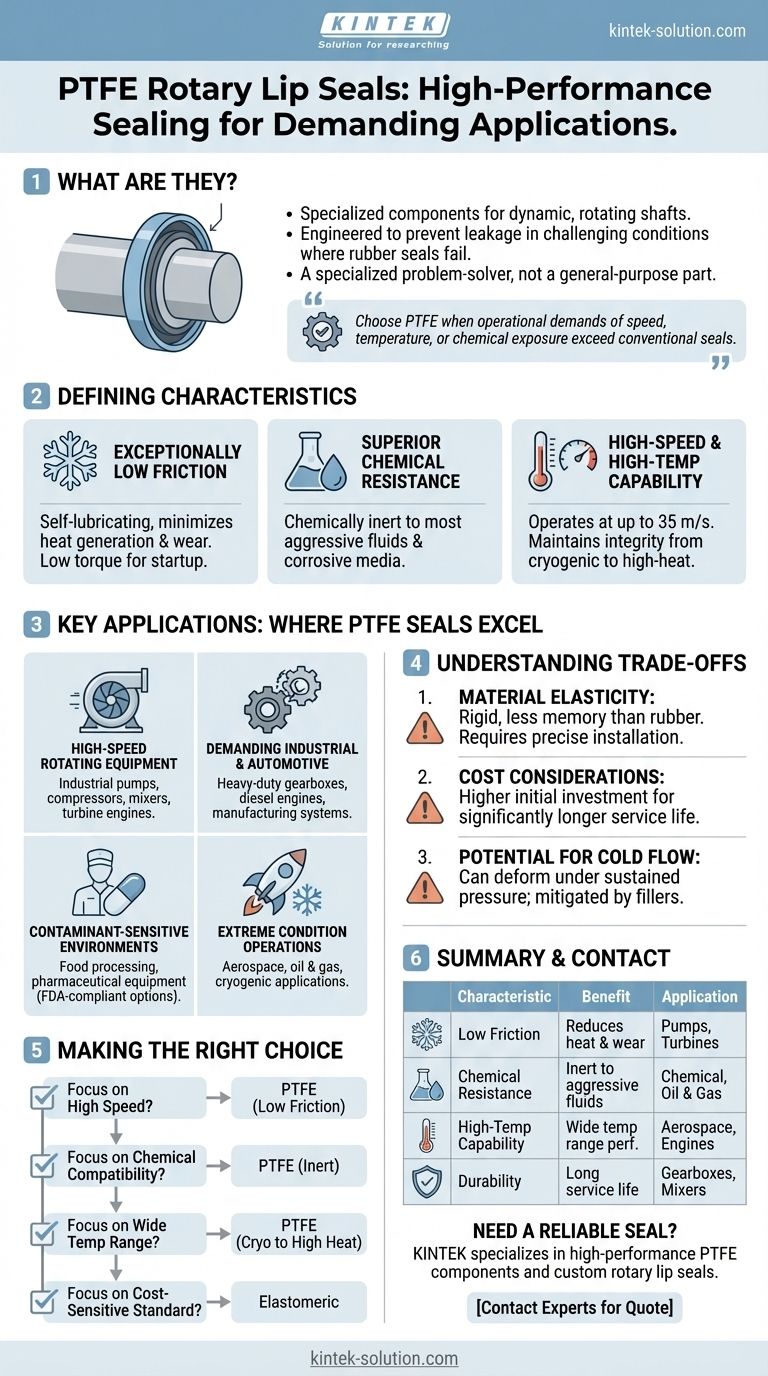

The Defining Characteristics of PTFE Seals

To understand their applications, you must first understand the unique properties of the material itself. PTFE's characteristics directly address the most common failure points of seals in demanding environments.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often as low as 0.04. This makes it inherently self-lubricating.

This property is critical for minimizing heat generation, reducing wear on the shaft, and lowering the torque required for rotation, especially during startup.

Superior Chemical Resistance

PTFE is a fluoropolymer, making it chemically inert to most industrial chemicals and fluids.

This makes it the ideal choice for equipment in the oil and gas, pharmaceutical, and chemical processing industries, where seals are exposed to aggressive or corrosive media.

High-Speed and High-Temperature Capability

The combination of low friction and high heat resistance allows PTFE seals to operate at shaft surface speeds up to 35 m/s.

Where traditional rubber seals would soften, degrade, or melt, PTFE maintains its structural integrity and sealing performance across a vast temperature range, from cryogenic applications to high-heat engines.

Where PTFE Seals Excel: Key Applications

The unique properties of PTFE make it the definitive choice for specific, high-stakes operational environments.

High-Speed Rotating Equipment

Applications like industrial pumps, compressors, mixers, and turbine engines involve constant, high-speed rotation that generates significant frictional heat.

PTFE seals excel here because their low-friction nature prevents the heat buildup that leads to premature seal failure.

Demanding Industrial and Automotive Systems

In systems like heavy-duty gearboxes, diesel engines, and manufacturing equipment, seals must be incredibly durable to withstand high pressure and continuous use.

The robustness of PTFE provides a reliable, long-lasting sealing solution that minimizes downtime and maintenance.

Contaminant-Sensitive Environments

The food processing and pharmaceutical industries require seals that are not only chemically resistant but also will not contaminate the product.

Because PTFE is inert and can be manufactured with FDA-compliant fillers, it provides a clean and reliable seal for mixers, blowers, and other processing equipment.

Extreme Condition Operations

Aerospace systems, oil and gas equipment, and cryogenic applications present a combination of extreme temperatures, high pressures, and aggressive chemicals.

PTFE is one of the few materials that can provide reliable sealing across all of these challenging variables simultaneously.

Understanding the Trade-offs

While highly effective, PTFE seals are a specialized solution with specific considerations. Objectivity requires acknowledging their limitations.

Material Elasticity

Compared to rubber, PTFE is a relatively rigid material. It has less "memory" and is less forgiving of imperfections in the shaft or housing surface.

Proper installation and precise machining of mating surfaces are critical to ensure a reliable, leak-free seal.

Cost Considerations

PTFE is a premium, high-performance polymer. The initial cost of a PTFE seal is typically higher than that of a standard elastomeric seal.

The higher upfront cost is justified by significantly longer service life, reduced maintenance, and greater reliability in the harsh conditions they are designed for.

Potential for Cold Flow

Under sustained high pressure and temperature, PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms over time.

Modern PTFE seals often mitigate this by incorporating fillers like carbon, glass, or bronze, which enhance dimensional stability without compromising core performance.

Making the Right Choice for Your Application

Selecting the correct seal material is crucial for system reliability. Your decision should be based on the most demanding aspect of your operating environment.

- If your primary focus is high rotational speed: The low-friction and heat-resistant properties of PTFE are essential to prevent overheating and premature failure.

- If your primary focus is chemical compatibility: PTFE's chemical inertness provides unmatched reliability when sealing aggressive or corrosive fluids.

- If your primary focus is a wide operating temperature range: PTFE seals maintain their integrity from cryogenic lows to high-heat environments where elastomers would fail.

- If your primary focus is a standard, cost-sensitive application: A traditional elastomeric (rubber) seal may be the more practical and economical choice for less demanding conditions.

Ultimately, selecting a PTFE rotary lip seal is a strategic engineering decision to ensure reliability where performance cannot be compromised.

Summary Table:

| Characteristic | Benefit | Key Application |

|---|---|---|

| Low Friction | Reduces heat & wear, ideal for high speeds | Pumps, compressors, turbines |

| Chemical Resistance | Inert to most aggressive fluids | Chemical processing, oil & gas |

| High-Temp Capability | Performs from cryogenic to high heat | Aerospace, automotive, engines |

| Durability | Long service life in harsh conditions | Heavy-duty gearboxes, mixers |

Need a reliable seal for demanding conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom rotary lip seals. Our precision production ensures your seals meet the exact demands of your application—whether in the semiconductor, medical, laboratory, or industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a sealing solution that delivers unmatched reliability, reduces downtime, and extends equipment life.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability