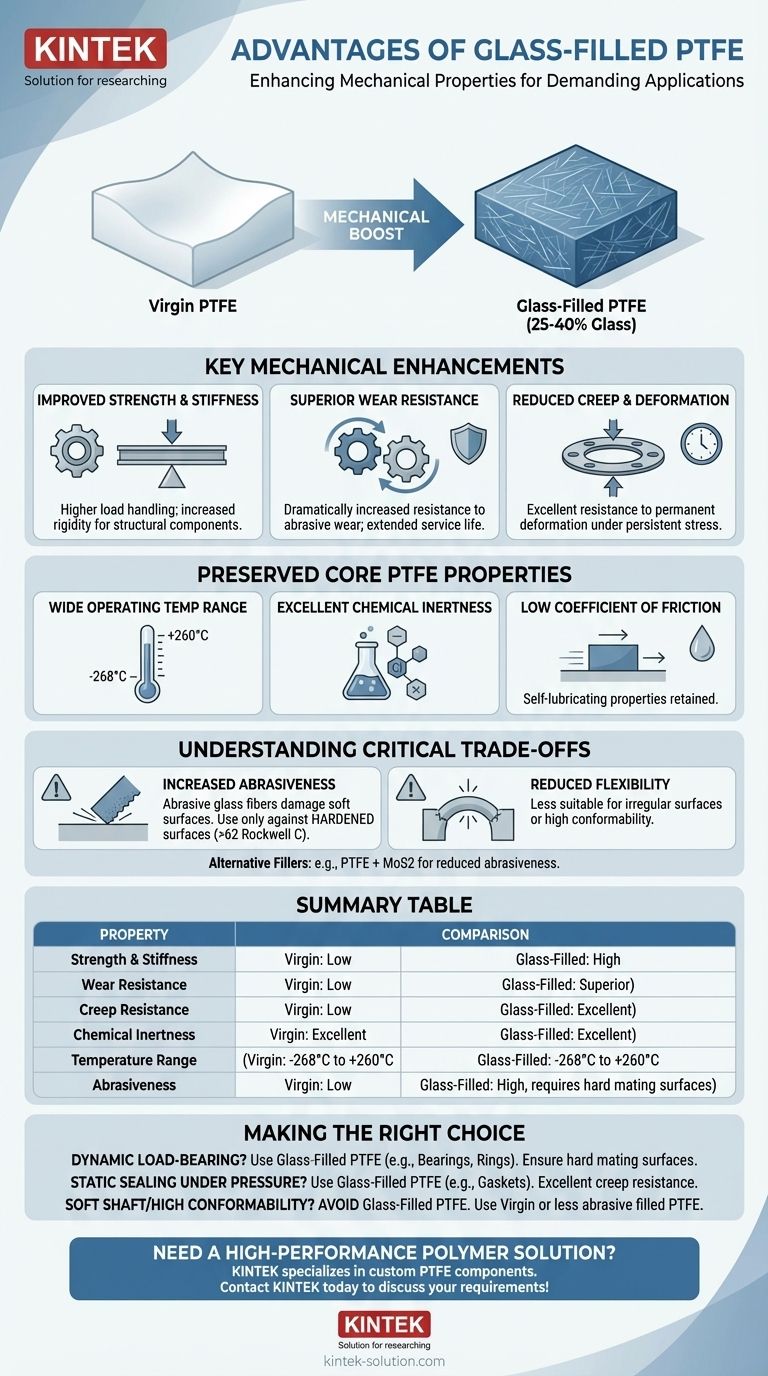

The primary advantage of adding glass fibers to PTFE is a significant enhancement of its mechanical properties. Compared to its unfilled (virgin) counterpart, glass-filled PTFE offers substantially improved strength, stiffness, wear resistance, and resistance to "creep" or deformation under load. This transforms a relatively soft material into a durable, load-bearing polymer ideal for more demanding applications.

The decision to use glass-filled PTFE is about overcoming the mechanical limitations of virgin PTFE. While retaining PTFE's excellent chemical and thermal resistance, the glass filler adds the structural integrity needed for components that must resist wear, pressure, and deformation over time.

Key Mechanical Enhancements Explained

The addition of glass fibers, typically in a 25% to 40% concentration, fundamentally changes the performance profile of PTFE. This makes it suitable for applications where virgin PTFE would fail due to mechanical stress.

Improved Strength and Stiffness

Glass-filled PTFE is significantly stronger and more rigid than unfilled PTFE. This increased stiffness allows it to handle higher loads without flexing, making it a superior choice for structural components.

Superior Wear Resistance

This is one of the most critical benefits. The glass fibers distributed within the PTFE matrix dramatically increase the material's resistance to abrasive wear, extending the service life of components in dynamic applications.

Reduced Creep and Deformation

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress. Glass-filled PTFE has excellent creep resistance, ensuring that seals, gaskets, and bearings maintain their shape and integrity under constant pressure.

Preserved Core PTFE Properties

Crucially, the addition of glass filler enhances mechanical properties without sacrificing the core attributes that make PTFE such a valuable material.

Wide Operating Temperature Range

Glass-filled PTFE maintains an exceptionally wide service temperature range, performing reliably from cryogenic conditions (-268°C) up to high heat (+260°C).

Excellent Chemical Inertness

The material remains chemically neutral and is suitable for use with most aggressive chemicals and in oxidizing environments. This makes it ideal for seals and gaskets in demanding industrial settings.

Low Coefficient of Friction

While the material is more abrasive, the base PTFE polymer still provides self-lubricating properties. This helps reduce friction in moving parts like bearings and compressor rings.

Understanding the Critical Trade-offs

No material choice is without compromise. To use glass-filled PTFE effectively, you must understand its limitations.

Increased Abrasiveness

This is the most significant drawback. The hard glass fibers will abrade and damage soft mating surfaces. It is critical to only use glass-filled PTFE against very hard surfaces, such as shafts hardened to over 62 Rockwell C.

Reduced Flexibility

The same stiffness that provides strength also reduces the material's flexibility. It is less suitable for applications that require the seal or part to conform to highly irregular surfaces compared to virgin PTFE.

A Note on Alternative Fillers

If the abrasiveness of glass is a concern for your application, other filled PTFE variants exist. For example, a compound filled with 15% glass and 5% Molybdenum Disulfide (MoS2) retains enhanced wear resistance while being less abrasive to mating surfaces.

Making the Right Choice for Your Application

Choosing the right material depends entirely on the demands of your specific application.

- If your primary focus is dynamic, load-bearing parts: Use glass-filled PTFE for its superior wear resistance and strength in applications like bearings, wear pads, and compressor rings, ensuring the mating surface is sufficiently hardened.

- If your primary focus is static sealing under high pressure: Its excellent creep resistance makes glass-filled PTFE ideal for gaskets that must maintain a seal without deforming over time.

- If your application involves a soft shaft or needs high conformability: Avoid glass-filled PTFE. Virgin PTFE or a less abrasive filled compound (like PTFE + MoS2) is a much safer and more effective choice.

By understanding these properties and their associated trade-offs, you can confidently select the right material to ensure long-term performance and reliability in your design.

Summary Table:

| Property | Virgin PTFE | Glass-Filled PTFE |

|---|---|---|

| Strength & Stiffness | Low | High |

| Wear Resistance | Low | Superior |

| Creep Resistance | Low | Excellent |

| Chemical Inertness | Excellent | Excellent |

| Temperature Range | -268°C to +260°C | -268°C to +260°C |

| Abrasiveness | Low | High (requires hard mating surfaces) |

Need a high-performance polymer solution for your demanding application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including high-performance glass-filled PTFE seals, liners, and wear parts. Our expertise ensures you get the optimal material for superior strength, wear resistance, and long-term reliability in the most challenging environments.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs