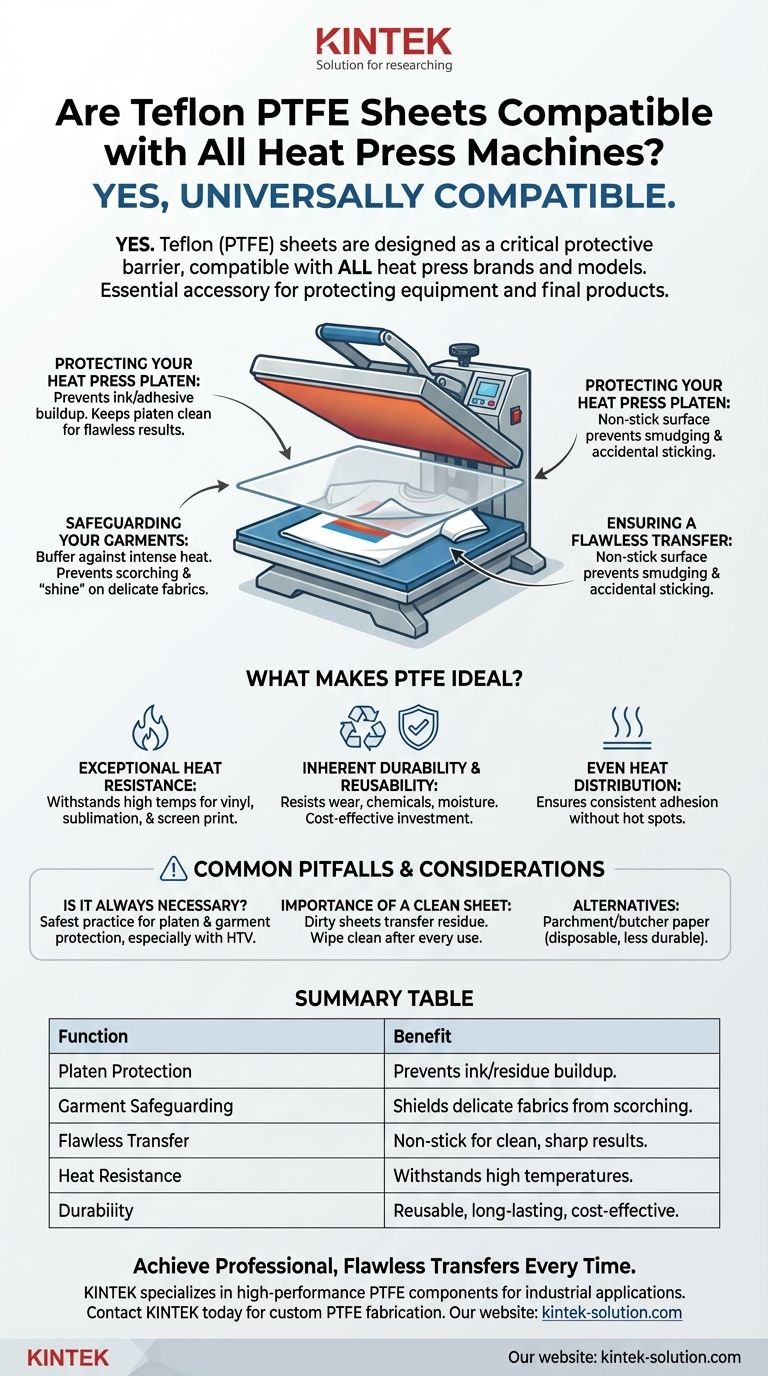

In short, yes. Teflon (PTFE) sheets are universally compatible with all types of heat press machines. They are designed to function as a critical protective barrier, sitting between your heated upper platen and your transfer project, regardless of the machine's brand or model.

The question isn't whether a Teflon sheet is compatible with your heat press, but rather understanding that it is an essential accessory for protecting both your equipment and your final product from damage.

Why a Teflon Sheet is a Core Component of Your Workflow

A Teflon sheet serves several distinct, critical functions that improve the quality of your work and the lifespan of your equipment. It acts as a reusable, non-stick shield during the heat transfer process.

Protecting Your Heat Press Platen

The upper platen of your heat press is the hot metal plate that applies pressure. Over time, inks, adhesives from heat transfer vinyl (HTV), and other residues can melt onto this surface.

A Teflon sheet prevents this buildup entirely. By keeping the platen clean, you eliminate the risk of old, stray residue accidentally transferring onto your next project.

Safeguarding Your Garments

Direct contact with a high-temperature metal platen can damage certain materials.

The sheet acts as a buffer, protecting delicate fabrics from scorching or getting a "shine" from the intense heat. It ensures the heat is distributed evenly without causing discoloration.

Ensuring a Flawless Transfer

The most valued property of Teflon is its non-stick surface.

This prevents inks from smudging and stops transfer materials from accidentally sticking to the upper platen as you lift the press. The result is a cleaner, sharper, and more professional finish.

Understanding the Material: What Makes PTFE Ideal?

The material itself, Polytetrafluoroethylene (PTFE), is a highly resilient synthetic polymer with a unique combination of properties perfect for heat pressing.

Exceptional Heat Resistance

PTFE can withstand the high temperatures required for all common heat transfer applications, including vinyl, sublimation, and screen print transfers, without degrading.

Inherent Durability and Reusability

Unlike single-use alternatives like parchment paper, a Teflon sheet is highly durable and reusable. It resists frictional wear, chemicals, and moisture, making it a cost-effective investment that can last for hundreds or even thousands of presses.

Even Heat Distribution

The sheet helps to distribute the heat from the platen more evenly across the surface of your design. This consistency is crucial for ensuring that the entire transfer adheres properly without hot spots.

Common Pitfalls and Considerations

While universally beneficial, understanding how to use a Teflon sheet correctly is key to avoiding common mistakes.

Is It Always Necessary?

For most applications like HTV, a protective sheet is non-negotiable. For sublimation, while it is highly recommended for preventing ink blow-out and staining, some professionals with perfectly calibrated settings may work without one.

However, using a sheet is always the safest practice to guarantee protection for your platen and garment.

The Importance of a Clean Sheet

A dirty Teflon sheet can ruin a project. If it has old ink or adhesive residue on it, that residue will be transferred to your new garment.

Always wipe your sheet clean after use, especially if you see any visible residue, to ensure it's ready for the next press.

Alternatives to Teflon

While Teflon sheets are the professional standard, parchment paper or butcher paper can be used as a disposable alternative. They provide a similar non-stick, protective layer but lack the durability and longevity of a true PTFE sheet.

Making the Right Choice for Your Goal

Using a Teflon sheet correctly is a simple step that elevates the quality and consistency of your work.

- If your primary focus is protecting your equipment: Always place a Teflon sheet over your design to keep the upper platen pristine and prevent residue buildup.

- If your primary focus is working with delicate fabrics: Use the sheet to shield the material from direct, intense heat, which minimizes the risk of scorching or unwanted shine.

- If your primary focus is achieving clean, sharp transfers: Rely on the sheet's non-stick surface to prevent smudging or vinyl from lifting as you open the press.

Integrating a Teflon sheet into your workflow is a fundamental practice that delivers significant returns in quality, efficiency, and equipment longevity.

Summary Table:

| Function | Benefit |

|---|---|

| Platen Protection | Prevents ink/residue buildup on the heat press plate. |

| Garment Safeguarding | Shields delicate fabrics from scorching and shine. |

| Flawless Transfer | Non-stick surface ensures clean, sharp results. |

| Heat Resistance | Withstands high temperatures without degrading. |

| Durability | Reusable and long-lasting, unlike disposable alternatives. |

Achieve Professional, Flawless Transfers Every Time

Ready to protect your heat press and elevate your projects? The right PTFE sheet makes all the difference. KINTEK specializes in manufacturing high-performance, durable PTFE components for industrial and specialized applications. Our expertise in precision production ensures you get a reliable, long-lasting sheet that stands up to the demands of your workflow.

Contact KINTEK today to discuss your needs for custom PTFE fabrication, from prototypes to high-volume orders, and ensure your equipment and products are always protected.

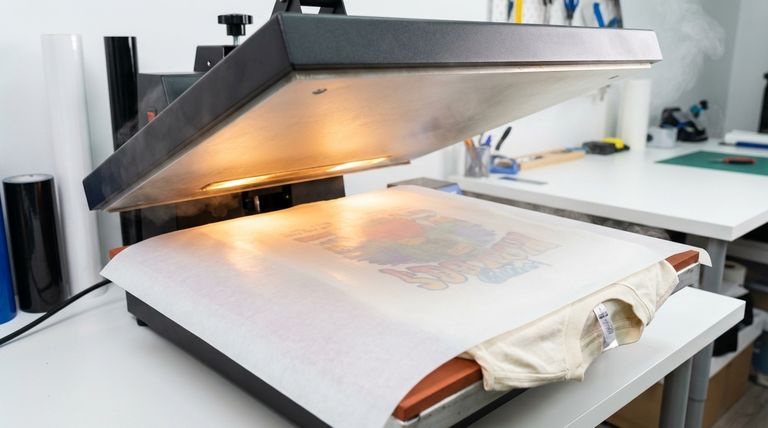

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the compression and rebound characteristics of ePTFE gaskets? Master Sealing for Demanding Flanges

- How do the anti-adhesion properties of Teflon gland fillers benefit handling viscous liquids? Prevent Clogs and Downtime

- What should be placed between a shirt and a heat press? Protect Your Gear with the Right Barrier

- What are the diameter tolerances for PTFE balls? A Guide to Precision vs. Standard Grades

- What are the key advantages of using PTFE fasteners in medical devices? Ensure Safety and Reliability in Critical Applications

- What are the advantages of spring-energized PTFE seals? Achieve Superior Sealing in Extreme Conditions

- How should seals and gaskets be maintained in PTFE butterfly valves? A Proactive Guide to Prevent Downtime

- What are the unique features of PTFE Lined Pressure Seal Valves? The Ultimate Solution for High-Pressure, Corrosive Applications