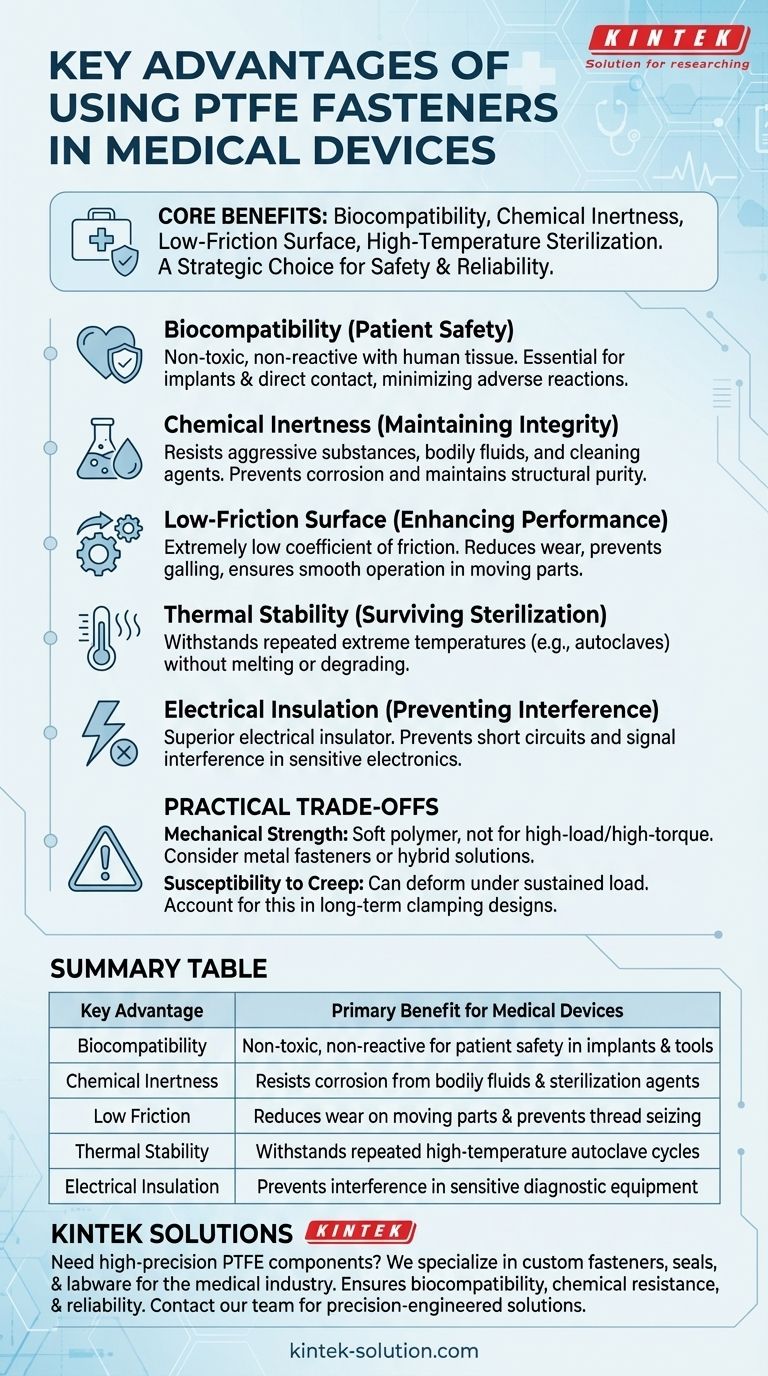

In the context of medical device engineering, the key advantages of using PTFE fasteners stem directly from the material's unique combination of properties. They are chosen for their exceptional biocompatibility, chemical inertness, low-friction surface, and ability to withstand high-temperature sterilization processes, making them a cornerstone of safety and reliability in critical applications.

The decision to use PTFE fasteners goes beyond simple component selection. It is a strategic choice to mitigate the inherent risks of medical applications, ensuring devices remain safe for patients, resistant to degradation from bodily fluids and chemicals, and mechanically reliable over their intended lifespan.

The Core Pillars of PTFE in Medical Applications

The value of Polytetrafluoroethylene (PTFE) in medical devices is not based on a single attribute but on the synergy of several distinct properties. Each one addresses a specific challenge common in healthcare environments.

Ensuring Patient Safety with Biocompatibility

Biocompatibility is the most critical property for any material in prolonged contact with the human body.

PTFE is non-toxic and non-reactive with human tissue, which is essential for implants, surgical tools, and any device that comes into direct contact with patients. This inert nature minimizes the risk of adverse reactions or rejection.

Maintaining Integrity with Chemical Inertness

Medical devices are consistently exposed to a range of aggressive substances, from bodily fluids to harsh cleaning and sterilization agents.

PTFE's chemical resistance ensures that the fasteners will not corrode or degrade in these environments. This prevents material failure and maintains the structural integrity and purity of the device.

Enhancing Performance with a Low-Friction Surface

Many medical devices feature moving parts or require frequent assembly and disassembly for maintenance and cleaning.

The extremely low coefficient of friction of PTFE is a major mechanical advantage. It reduces wear and tear on moving components, prevents galling or seizing of threads, and allows for smooth, reliable operation throughout the device's life.

Surviving Sterilization with Thermal Stability

Effective sterilization is non-negotiable in medicine, and the processes often involve extreme temperatures, such as in an autoclave.

PTFE fasteners possess excellent thermal stability, allowing them to maintain their shape and mechanical properties during repeated high-temperature sterilization cycles without melting or degrading.

Preventing Interference with Electrical Insulation

Modern medical equipment often integrates sophisticated electronics where signal integrity is paramount.

As a superior electrical insulator, PTFE prevents short circuits and electrical interference. This makes its fasteners ideal for mounting components in sensitive diagnostic and monitoring equipment.

Understanding the Practical Trade-offs

While PTFE offers significant advantages, it is essential to understand its limitations to make an informed engineering decision. No material is universally perfect.

Mechanical Strength Considerations

PTFE is a relatively soft polymer compared to metals. It is not suitable for high-load or high-torque applications where the primary function is structural clamping force.

In these scenarios, fasteners made from medical-grade stainless steel or titanium are the superior choice. Sometimes, a metal fastener with a PTFE coating can provide a hybrid solution.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time, a phenomenon known as creep.

Engineers must account for this in designs that require a precise, long-term clamping force, as the fastener may loosen over its service life if not specified correctly.

Making the Right Choice for Your Device

Your material selection must align directly with the specific functional demands and operating environment of the medical device.

- If your primary focus is implants or direct tissue contact: Prioritize PTFE for its unparalleled biocompatibility and chemical inertness to ensure patient safety.

- If your primary focus is devices with moving parts or frequent adjustments: Leverage PTFE's low-friction properties to guarantee smooth operation, minimize wear, and prevent thread damage.

- If your primary focus is high-load structural integrity: Carefully evaluate whether PTFE's mechanical strength is sufficient, or if a metal fastener is the more appropriate choice.

Ultimately, specifying PTFE fasteners is a deliberate engineering decision that places a premium on long-term safety and functional reliability in the most demanding medical environments.

Summary Table:

| Key Advantage | Primary Benefit for Medical Devices |

|---|---|

| Biocompatibility | Non-toxic, non-reactive for patient safety in implants and tools |

| Chemical Inertness | Resists corrosion from bodily fluids and sterilization agents |

| Low Friction | Reduces wear on moving parts and prevents thread seizing |

| Thermal Stability | Withstands repeated high-temperature autoclave cycles |

| Electrical Insulation | Prevents interference in sensitive diagnostic equipment |

Need high-precision PTFE components for your medical device? At KINTEK, we specialize in manufacturing custom PTFE fasteners, seals, and labware that meet the stringent demands of the medical industry. Our expertise ensures your components deliver the critical biocompatibility, chemical resistance, and reliability your applications require—from prototypes to high-volume production. Contact our team today to discuss how we can support your next project with precision-engineered solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability