The primary benefit of Teflon's anti-adhesion is its ability to create a non-stick surface that prevents viscous, sticky liquids from building up on critical sealing components. This resistance to material accumulation ensures consistent sealing performance, prevents blockages, and significantly reduces the operational friction and wear that lead to equipment downtime.

While Teflon's non-stick surface is its most visible advantage for sticky fluids, its true value lies in the powerful combination of anti-adhesion and an extremely low friction coefficient. This dual-action property not only prevents clogs but also minimizes wear and energy loss, leading to a more reliable and efficient system overall.

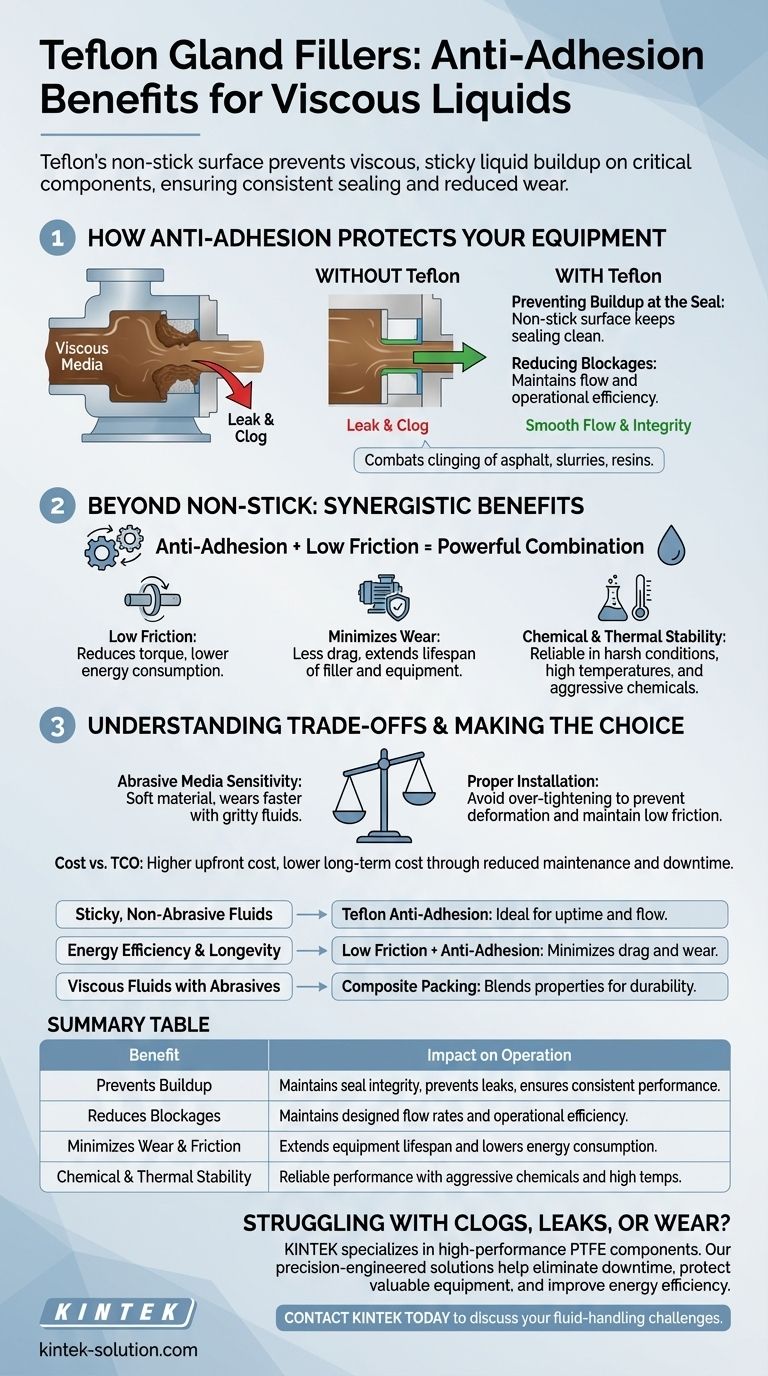

How Anti-Adhesion Protects Your Equipment

When handling high-viscosity media like asphalt, slurries, or resins, the primary challenge is the material's tendency to cling to every surface it touches. Teflon's unique properties directly counter this problem.

Preventing Material Buildup at the Seal

The most critical function of a gland filler is to create a seal. Viscous materials can accumulate on the filler, hardening over time and compromising the seal's integrity, which inevitably leads to leaks.

Teflon's anti-adhesion ensures that the media slides past the filler instead of sticking to it. This keeps the sealing surface clean and maintains a consistent, effective seal.

Reducing System Blockages and Maintaining Flow

Buildup is not just a problem at the seal. Adhesion within pumps and pipes can restrict flow, increase system pressure, and demand more energy to move the product.

By using Teflon fillers in pumps, the internal components remain clearer, helping to maintain designed flow rates and operational efficiency.

Beyond Non-Stick: The Synergistic Benefits of Teflon

The anti-adhesion property does not work in isolation. It is amplified by other inherent characteristics of Teflon, which together solve the deeper challenges of managing viscous fluids.

The Role of Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material. For equipment like pumps and valves with moving parts, this is a significant advantage.

This low friction reduces the rotational force (torque) needed to turn a pump shaft or actuate a valve, which translates directly to lower energy consumption and less stress on motors and drives.

Minimizing Wear and Extending Lifespan

High-viscosity fluids naturally increase drag and friction. When these fluids also adhere to surfaces, the effect is magnified, causing accelerated wear on both the sealing material and the equipment shaft itself.

Teflon's combination of anti-adhesion (less stick) and low friction (less drag) drastically reduces these abrasive forces. This extends the service life of not only the Teflon filler but also the expensive equipment it protects.

Ensuring Chemical and Thermal Stability

Many viscous fluids are also chemically aggressive or processed at high temperatures. Teflon's excellent chemical inertness and high-temperature stability ensure it will not degrade under these harsh conditions.

This reliability means the filler maintains its sealing and anti-adhesion properties consistently, whether handling hot asphalt or corrosive chemical compounds.

Understanding the Trade-offs

While highly effective, Teflon fillers are not a universal solution. Acknowledging their limitations is key to proper application.

Sensitivity to Abrasive Media

Teflon is a relatively soft material. If your viscous fluid contains hard, abrasive particles (e.g., a mineral slurry or gritty waste), the Teflon can wear down more quickly than harder packing materials.

Proper Installation is Critical

Gland packing requires correct installation to function properly. Over-tightening a Teflon filler can cause it to deform or extrude from the gland, or it can increase shaft friction, negating its low-friction benefits.

Cost vs. Total Cost of Ownership

Teflon-based fillers often have a higher upfront cost compared to traditional materials like graphite or flax. Their value is justified by a lower total cost of ownership, factoring in reduced maintenance, longer equipment life, and minimized production downtime.

Making the Right Choice for Your Application

To select the right material, you must align its properties with your primary operational goal.

- If your primary focus is preventing clogs with sticky, non-abrasive fluids: Teflon's anti-adhesion is the ideal solution for ensuring reliable system uptime and consistent flow.

- If your primary focus is energy efficiency and equipment longevity: The combination of Teflon's low friction and anti-adhesion minimizes both drag and wear on rotating parts, protecting your investment.

- If your primary focus is handling viscous fluids with abrasive particles: You may need a composite packing that blends Teflon's properties with a more wear-resistant material to balance performance and durability.

Ultimately, selecting Teflon gland fillers is an investment in operational stability when viscous media threatens to compromise your system.

Summary Table:

| Benefit | Impact on Your Operation |

|---|---|

| Prevents Material Buildup | Maintains seal integrity, prevents leaks, and ensures consistent performance. |

| Reduces Blockages | Maintains designed flow rates and operational efficiency in pumps and pipes. |

| Minimizes Wear & Friction | Extends equipment lifespan and lowers energy consumption. |

| Chemical & Thermal Stability | Reliable performance with aggressive chemicals and high temperatures. |

Struggling with clogs, leaks, or excessive wear from viscous liquids?

KINTEK specializes in manufacturing high-performance PTFE (Teflon) components, including custom gland fillers, seals, and liners. Our precision-engineered solutions are designed to provide the anti-adhesion and low-friction properties you need to:

- Eliminate downtime caused by material buildup and seal failure.

- Protect your valuable equipment from accelerated wear.

- Improve energy efficiency and reduce operational costs.

Whether you need a prototype or a high-volume order for the semiconductor, medical, laboratory, or industrial sectors, we deliver quality and reliability.

Contact KINTEK today to discuss your specific application and discover how our PTFE expertise can solve your toughest fluid-handling challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability