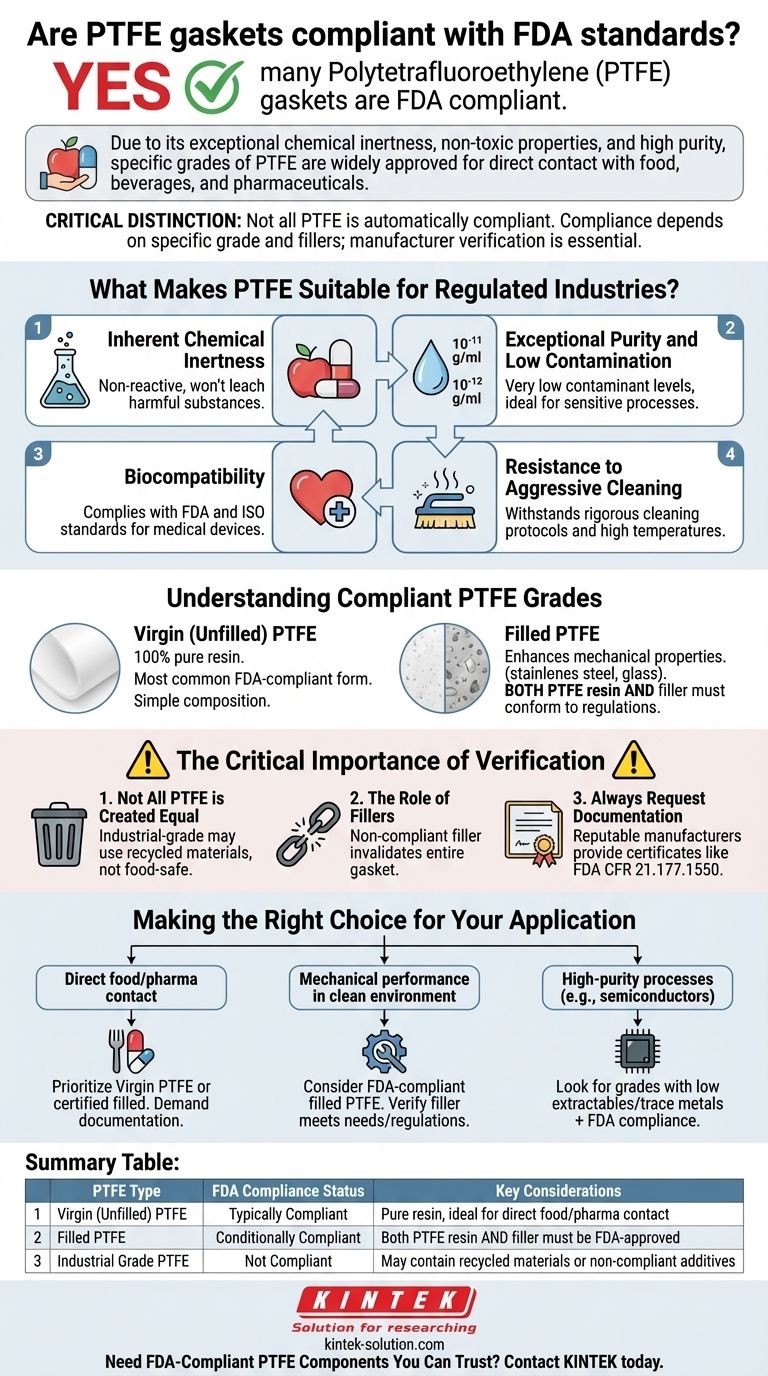

Yes, many Polytetrafluoroethylene (PTFE) gaskets are FDA compliant. Due to its exceptional chemical inertness, non-toxic properties, and high purity, specific grades of PTFE are widely approved and used for applications involving direct contact with food, beverages, and pharmaceuticals.

The critical distinction is that not all PTFE is automatically compliant. Compliance depends on the specific grade of the material and any fillers it may contain, making manufacturer verification an essential step for any regulated application.

What Makes PTFE Suitable for Regulated Industries?

The suitability of PTFE for sensitive applications is not accidental; it stems from a unique combination of inherent material properties that satisfy the stringent requirements of bodies like the FDA and USDA.

Inherent Chemical Inertness

PTFE is one of the most non-reactive substances known. This means it will not react with or leach harmful substances into the products it touches, whether they are food ingredients or active pharmaceutical compounds.

Exceptional Purity and Low Contamination

High-purity grades of PTFE maintain extremely low levels of contaminants. Some grades feature lead content below 10⁻¹¹ g/ml and uranium below 10⁻¹² g/ml, making them ideal for contamination-sensitive processes.

Biocompatibility

For medical applications, specific grades of medical PTFE liners and components comply with both FDA and ISO standards. This certification confirms the material is biocompatible and safe for use in medical devices.

Resistance to Aggressive Cleaning

Regulated industries rely on rigorous cleaning and sterilization protocols. PTFE's high-temperature resistance and minimal moisture absorption allow it to withstand these aggressive processes without degrading, ensuring a hygienic environment.

Understanding Compliant PTFE Grades

Compliance isn't a feature of the general material but of specific formulations. The primary distinction is between pure, virgin PTFE and PTFE that has been modified with fillers.

Virgin (Unfilled) PTFE

Virgin PTFE, made from 100% pure resin, is the most common form that meets FDA regulations. Its simple, unadulterated composition makes it a straightforward choice for food-contact applications.

Filled PTFE

Fillers are added to PTFE to enhance mechanical properties like strength or wear resistance. For a filled PTFE gasket to be FDA compliant, both the PTFE resin and the filler material must conform to regulations. Common FDA-compliant fillers include stainless steel, glass, and certain pigments.

The Critical Importance of Verification

Assuming any PTFE product is compliant without confirmation is a significant risk. The difference between an industrial-grade and a food-grade material can have serious safety and regulatory consequences.

Not All PTFE is Created Equal

An industrial-grade PTFE gasket may be manufactured with recycled materials or processing aids that are not approved for food contact. It will not have the purity required for sensitive applications.

The Role of Fillers

A non-compliant filler immediately invalidates the gasket's suitability for food, beverage, or medical use. Always verify the compliance status of the entire composite material, not just the base PTFE resin.

Always Request Documentation

The only way to ensure compliance is to obtain it in writing. Reputable manufacturers will readily provide a certificate of compliance that explicitly states the material conforms to relevant regulations, such as FDA CFR 21.177.1550.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its certified properties with your specific operational goal.

- If your primary focus is direct food or pharmaceutical contact: Prioritize virgin PTFE or a certified filled PTFE from a reputable supplier and always demand documentation.

- If your primary focus is mechanical performance in a clean environment: Consider an FDA-compliant filled PTFE, but verify that the filler meets both your performance needs and all regulatory requirements.

- If your primary focus is high-purity processes (e.g., semiconductors): Look for PTFE grades with documented low levels of extractables and trace metal content, in addition to standard FDA compliance.

Ultimately, diligent material verification is the key to ensuring both operational safety and regulatory compliance in your application.

Summary Table:

| PTFE Type | FDA Compliance Status | Key Considerations |

|---|---|---|

| Virgin (Unfilled) PTFE | Typically Compliant | Pure resin, ideal for direct food/pharma contact |

| Filled PTFE | Conditionally Compliant | Both PTFE resin AND filler must be FDA-approved |

| Industrial Grade PTFE | Not Compliant | May contain recycled materials or non-compliant additives |

Need FDA-Compliant PTFE Components You Can Trust?

At KINTEK, we specialize in manufacturing high-purity PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We understand that compliance isn't optional—it's essential for your product's safety and success.

We provide full documentation and certificates of compliance (including FDA CFR 21.177.1550) with every order, ensuring the materials meet the strictest standards for your application. From custom prototypes to high-volume production, our precision manufacturing guarantees reliability.

Contact KINTEB today to discuss your specific requirements and receive a quote for FDA-compliant PTFE solutions.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the benefits of FEP-encapsulated O-Rings? Superior Sealing for Harsh Chemical & High-Temp Environments

- Why is PTFE considered a benchmark for low-friction materials? Unmatched Performance for Smooth Motion

- What types of gasket materials are available besides PTFE? Find the Perfect Seal for Your Application

- Why are Teflon bellow mechanical seals suitable for pulp and paper manufacturing?

- Why are Metal-Polymer Bronze Backed PTFE Plain Bearings considered versatile? Unlock Maintenance-Free, High-Performance Solutions

- What factors influence the properties of compression molded PTFE parts? Master the 4 Key Processing Parameters

- What are the benefits of CNC machining for PTFE parts? Achieve Precision and Performance

- What is the purpose of sintering in the PTFE bush manufacturing process? | Achieve Superior Component Performance