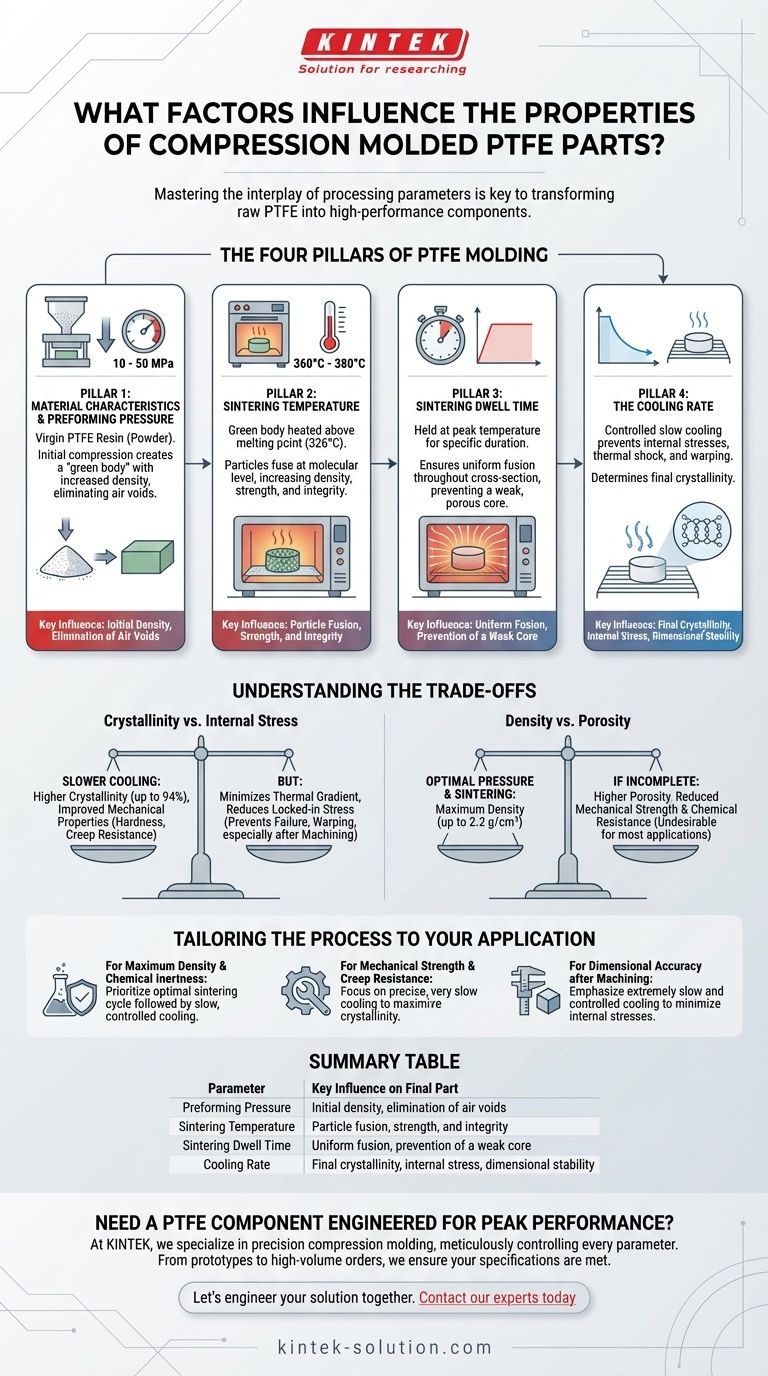

The final properties of a compression molded PTFE part are fundamentally controlled by four interconnected processing parameters. These are the preforming pressure applied to the raw powder, the sintering temperature and duration, and the rate at which the part is cooled. Mastering the interplay between these stages is the key to transforming raw PTFE powder into a high-performance component with predictable characteristics.

The compression molding of PTFE is not merely a shaping process; it is a carefully orchestrated thermal and mechanical cycle. Each step—from initial compression to final cooling—builds upon the last to define the material's final molecular structure, density, and mechanical integrity.

The Four Pillars of PTFE Molding

The journey from a loose powder to a solid, functional part involves a sequence of critical steps. An error or inconsistency in any one of these stages will directly impact the quality and performance of the final product.

Pillar 1: Material Characteristics & Preforming Pressure

The process begins with virgin PTFE resin, a fine powder. This powder is loaded into a mold and subjected to high pressure, typically between 10 and 50 MPa.

This initial compression transforms the loose powder into a fragile, high-density compact known as a "green body." The amount of pressure directly influences the initial density and helps eliminate air voids between particles, setting the stage for an effective sintering process.

Pillar 2: Sintering Temperature

The green body is then heated in a precisely controlled oven to a temperature between 360°C and 380°C, which is above PTFE's melting point of 326°C.

During sintering, the individual PTFE particles fuse together at a molecular level. This process eliminates the microscopic voids that remained after preforming, significantly increasing the part's density, strength, and overall integrity.

Pillar 3: Sintering Dwell Time

The part must be held at the peak sintering temperature for a specific duration, known as dwell time.

This is not a step to be rushed. Sufficient dwell time ensures that the entire cross-section of the part reaches a uniform temperature, allowing for complete particle fusion. Inadequate dwell time can result in a part with a well-sintered exterior but a weak, porous core.

Pillar 4: The Cooling Rate

After sintering, the part is cooled back to room temperature. This is arguably the most critical and often overlooked stage.

A slow, controlled cooling rate is essential to prevent the buildup of internal stresses. Rapid cooling can cause thermal shock, leading to cracks, warping, and poor dimensional stability. The cooling profile also directly determines the material's final crystallinity.

Understanding the Trade-offs

The choices made during the molding process involve balancing competing properties. Understanding these trade-offs is essential for producing a part that is optimized for its intended application.

Crystallinity vs. Internal Stress

A slower cooling rate allows the polymer chains more time to organize into highly ordered crystalline structures, typically increasing the part's crystallinity (up to 94%). Higher crystallinity often improves mechanical properties like hardness and creep resistance.

However, the primary goal of slow cooling is to minimize the thermal gradient across the part, which is the root cause of locked-in stress that can lead to failure or warping, especially after secondary machining.

Density vs. Porosity

Optimal preforming pressure and a thorough sintering cycle are key to achieving maximum density, which can be as high as 2.2 g/cm³.

If pressure is too low or sintering is incomplete, the resulting part will have higher porosity. While undesirable for most applications, this could theoretically be manipulated for specialized uses, but it comes at the cost of mechanical strength and chemical resistance.

Tailoring the Process to Your Application

The ideal processing parameters depend entirely on the final requirements of the component. To achieve your desired outcome, consider the following guidelines.

- If your primary focus is maximum density and chemical inertness: Prioritize an optimal sintering cycle (temperature and time) followed by a slow, controlled cooling profile.

- If your primary focus is mechanical strength and creep resistance: Focus on a precise and very slow cooling rate to maximize the material's crystallinity.

- If your primary focus is dimensional accuracy after machining: Emphasize an extremely slow and controlled cooling process to minimize internal stresses, which are the primary cause of warping when material is removed.

By deliberately controlling these fundamental variables, you can reliably engineer PTFE components to meet exacting performance standards.

Summary Table:

| Parameter | Key Influence on Final Part |

|---|---|

| Preforming Pressure | Initial density, elimination of air voids |

| Sintering Temperature | Particle fusion, strength, and integrity |

| Sintering Dwell Time | Uniform fusion, prevention of a weak core |

| Cooling Rate | Final crystallinity, internal stress, dimensional stability |

Need a PTFE component engineered for peak performance? At KINTEK, we specialize in precision compression molding, meticulously controlling every parameter—from pressure to cooling—to deliver parts with the exact density, strength, and dimensional stability your application demands. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom fabrication services, from prototypes to high-volume orders, ensure your specifications are met.

Let's engineer your solution together. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials