The primary benefit of an FEP-encapsulated O-ring is its unique ability to combine the superior chemical and temperature resistance of a fluoropolymer (like Teflon®) with the flexibility and sealing force of a traditional elastomeric O-ring. This hybrid design creates a seal that is virtually immune to chemical attack from corrosive fluids and gases while still providing the reliable, elastic compression needed for effective sealing in harsh environments.

The core problem with standard rubber O-rings is that they must be chemically compatible with their environment, forcing engineers to choose a specific elastomer that may still degrade over time. FEP-encapsulated O-rings solve this by wrapping a standard elastomer core in a chemically inert FEP jacket, creating a single, robust sealing solution for the most demanding applications.

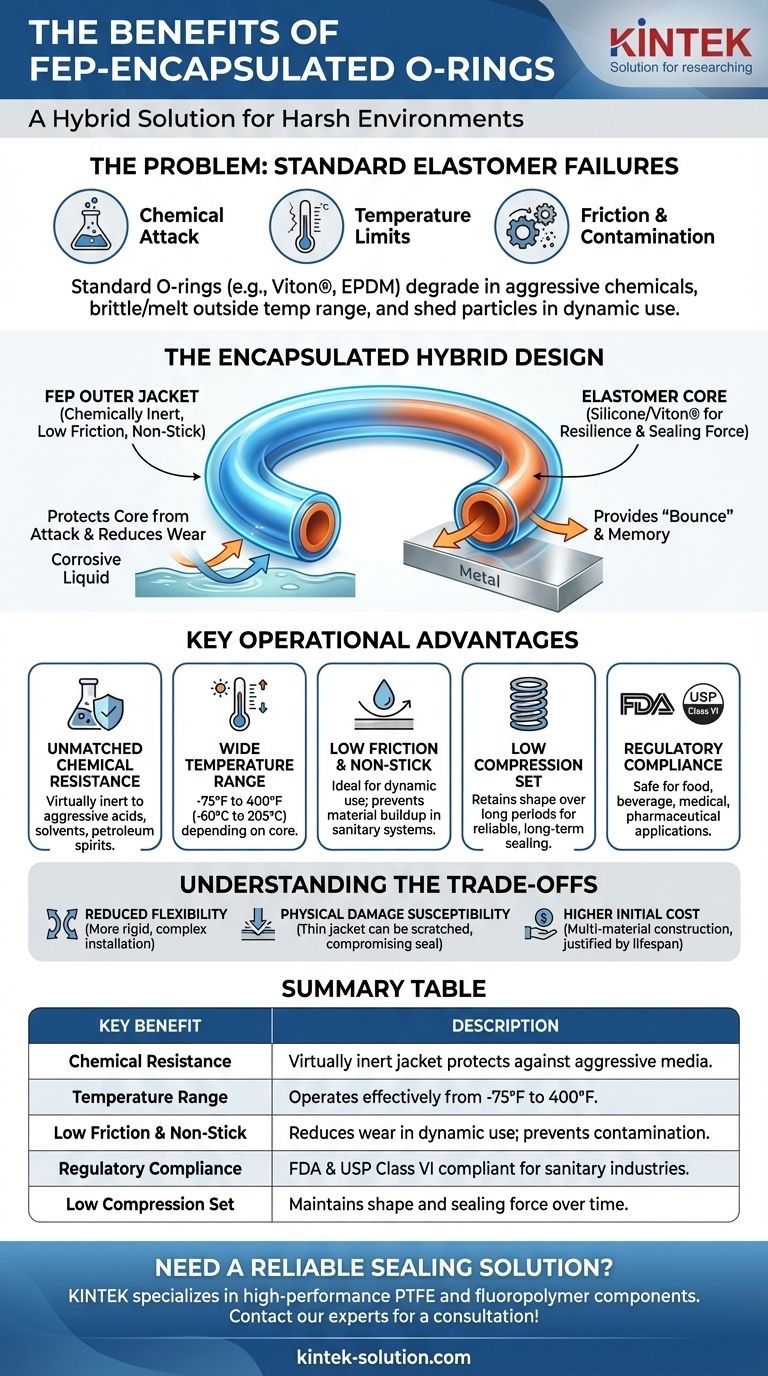

The Problem: Why Standard Elastomer Seals Fail

Before understanding the FEP-encapsulated solution, it's critical to recognize the limitations of conventional O-rings in aggressive operational conditions.

Chemical Attack and Degradation

Standard elastomers like Viton®, Silicone, or EPDM have specific chemical compatibilities. When exposed to incompatible fluids, such as aggressive acids, solvents, or alcohols, they can swell, soften, or break down, leading to premature seal failure.

Temperature Limitations

Every elastomer has a defined operating temperature range. Outside this range, they can become brittle at low temperatures or lose their elasticity and sealing force at high temperatures, resulting in leaks.

Friction and Contamination

In dynamic applications, the friction of a standard rubber seal can cause wear and stiction. In sanitary or high-purity systems, the elastomer itself can shed particles, leading to contamination.

The Encapsulated Solution: A Hybrid Design

FEP-encapsulated O-rings are engineered to overcome these failures by creating a seal with two distinct but synergistic components.

The Protective Outer Jacket

The outer layer is a seamless sheath of Fluorinated Ethylene Propylene (FEP), a fluoropolymer similar to PTFE (Teflon®). This jacket is the component that contacts the media. It is virtually chemically inert and provides a smooth, low-friction, non-stick surface.

The Resilient Inner Core

Inside the FEP jacket is a standard elastomeric O-ring, typically made of Silicone or Viton® (FKM). This inner core provides the "bounce" and memory, delivering the consistent outward force required to maintain a reliable seal against the hardware surfaces.

How They Work Together

The FEP jacket completely protects the vulnerable elastomeric core from chemical attack, while the core provides the resilience the rigid FEP material lacks on its own. This combination delivers the best properties of both materials in a single O-ring.

Key Benefits in Detail

This hybrid construction results in several distinct operational advantages that extend equipment lifespan and reduce costly downtime.

Unmatched Chemical Resistance

The FEP encapsulation is resistant to nearly all industrial chemicals, including aggressive acids, aromatic solvents, naphtha, and petroleum spirits. This prevents the seal degradation that plagues standard elastomers.

Wide Operational Temperature Range

FEP-encapsulated seals can operate effectively in a broad temperature range, typically from -75°F to 400°F (-60°C to 205°C), depending on the core material selected.

Low Friction and Non-Stick Surface

The FEP jacket has an extremely low coefficient of friction, making these O-rings ideal for dynamic applications where they reduce wear and ensure smooth operation. The non-stick surface also prevents material buildup in sanitary systems.

Low Compression Set

These seals exhibit a low compression set, meaning they retain their original shape after being compressed for long periods. This resilience is crucial for ensuring a reliable, long-term seal without frequent replacement.

Regulatory Compliance

Materials used are often FDA compliant and meet USP Class VI standards, making them a safe and proven choice for sanitary applications in the food, beverage, medical, and pharmaceutical industries.

Understanding the Trade-offs

While highly effective, encapsulated O-rings are not a universal solution. Understanding their limitations is key to proper application.

Reduced Flexibility

The FEP jacket is more rigid than a standard elastomer. This makes the O-ring less flexible, which can complicate installation and may require specialized groove designs to ensure proper seating and compression.

Susceptibility to Physical Damage

The protective FEP jacket is relatively thin. If it is scratched or nicked during installation, its chemical barrier is compromised, exposing the inner core to the aggressive media and leading to failure.

Higher Initial Cost

Due to their complex, multi-material construction, FEP-encapsulated O-rings are more expensive than standard, single-material O-rings. However, this cost is often justified by increased service life and reduced downtime in harsh environments.

Making the Right Choice for Your Application

Choosing the correct seal requires evaluating your primary operational challenge.

- If your primary focus is handling aggressive chemicals and solvents: FEP-encapsulated O-rings provide a robust barrier, preventing seal degradation where standard elastomers would fail.

- If your primary focus is high-purity or sanitary applications: Their compliance with FDA and USP Class VI standards, combined with a non-stick surface, makes them ideal for food, beverage, and pharmaceutical processes.

- If your primary focus is dynamic sealing with low friction: The low coefficient of friction of the FEP jacket reduces wear, prevents stiction, and ensures smooth, consistent operation.

- If your primary focus is a general-purpose application with compatible fluids: A conventional, single-material O-ring is likely the more flexible and cost-effective solution.

Ultimately, FEP-encapsulated O-rings provide a powerful sealing solution for the most challenging environments where other seals cannot survive.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Resistance | FEP jacket is virtually inert, protecting against aggressive acids, solvents, and chemicals. |

| Temperature Range | Operates effectively from -75°F to 400°F (-60°C to 205°C). |

| Low Friction & Non-Stick | Ideal for dynamic applications; reduces wear and prevents contamination. |

| Regulatory Compliance | Often FDA compliant and meets USP Class VI standards for sanitary industries. |

| Low Compression Set | Maintains shape and sealing force over long periods, ensuring reliability. |

Need a reliable sealing solution for harsh conditions?

FEP-encapsulated O-rings are engineered to solve the toughest sealing challenges in semiconductor, medical, laboratory, and industrial applications. At KINTEK, we specialize in manufacturing high-performance PTFE and fluoropolymer components, including custom O-rings. Our precision production ensures your seals deliver maximum chemical resistance, temperature stability, and longevity—from prototypes to high-volume orders.

Let us provide the perfect seal for your application. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance