The definitive reason PTFE is the benchmark for low-friction materials is its exceptionally low coefficient of friction, which is lower than nearly any other solid engineering material. With a coefficient of friction (CoF) as low as 0.04, it surpasses even lubricated steel and significantly outperforms other common plastics, creating a uniquely smooth, self-lubricating surface.

The core reason for PTFE's status is not just that its friction is low, but that it is consistently low for both static (at rest) and kinetic (in motion) conditions. This unique quality makes it the default standard for applications where minimizing resistance and preventing stick-slip phenomena are paramount.

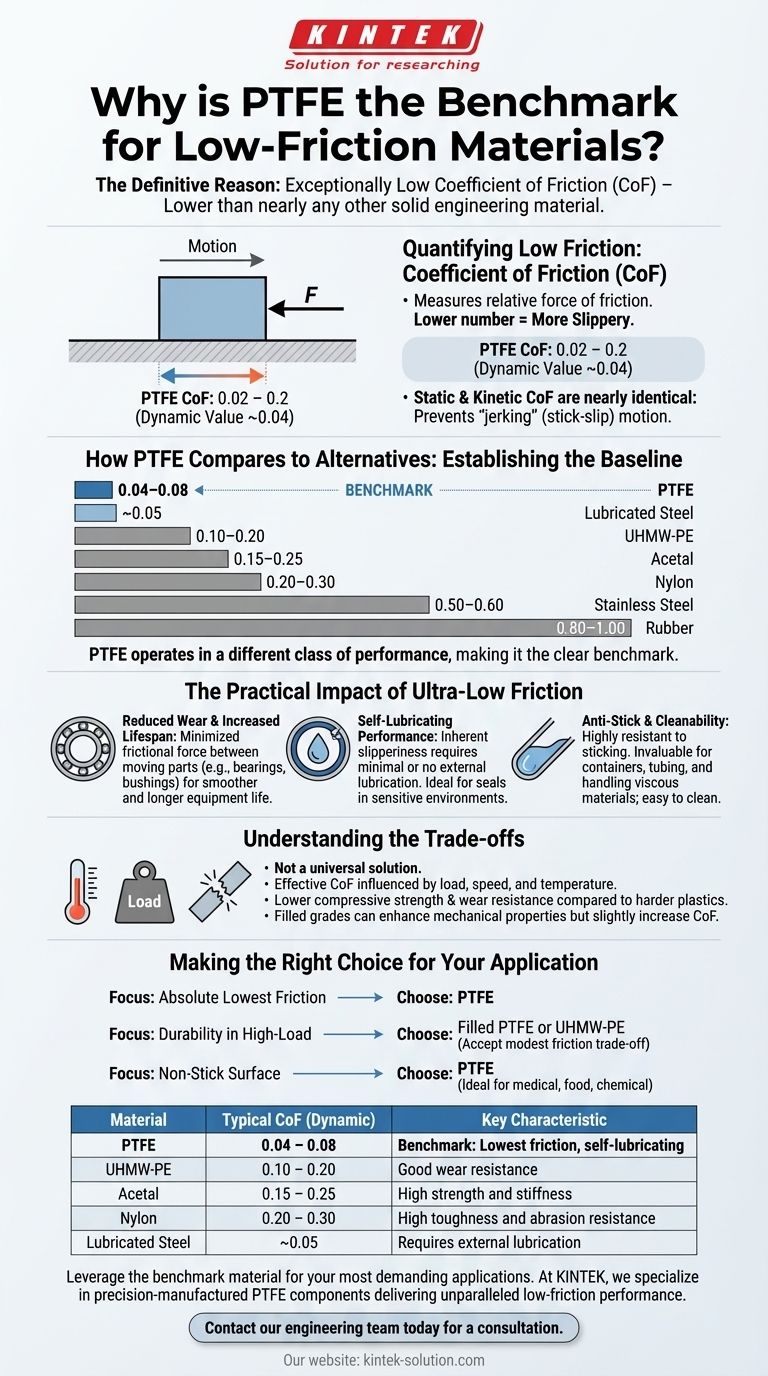

Quantifying PTFE's Low Friction

To understand why PTFE is a benchmark, we must first look at the numbers that define its performance. The coefficient of friction is a simple ratio, but its implications are profound.

The Coefficient of Friction (CoF)

The coefficient of friction measures the relative force of friction between two surfaces. A lower number signifies a "more slippery" or lower-friction interaction.

PTFE's CoF is exceptionally low, typically ranging from 0.02 to 0.2, depending on the specific test conditions and surface preparation. A commonly cited dynamic value is around 0.04.

Crucially, PTFE's static and kinetic coefficients of friction are nearly identical. This prevents the "jerking" motion (stick-slip) seen in other materials when transitioning from a resting state to motion.

How PTFE Compares to Alternatives

When placed alongside other common engineering materials, PTFE's advantage becomes immediately clear. Its performance establishes the baseline that other materials are measured against.

- PTFE: 0.04–0.08

- UHMW-PE: 0.10–0.20

- Acetal: 0.15–0.25

- Nylon: 0.20–0.30

- Lubricated Steel: 0.05 (kinetic)

- Stainless Steel: 0.50–0.60

- Rubber: 0.80–1.00

This data shows PTFE is not just slightly better; it operates in a different class of performance, making it the clear benchmark.

The Practical Impact of an Ultra-Low Friction Surface

The theoretical numbers translate directly into tangible engineering benefits across a wide range of industries, from medical devices to industrial machinery.

Reduced Wear and Increased Lifespan

By minimizing the frictional force between moving parts, PTFE reduces mechanical wear. This is critical in applications like bearings, bushings, and liners.

The result is smoother operation, lower energy consumption, and a significantly longer lifespan for the equipment.

Self-Lubricating Performance

PTFE's inherent slipperiness means it requires minimal or no external lubrication. This makes it the ideal choice for seals and components in environments where lubricants are impractical or could cause contamination.

Anti-Stick and Cleanability

The same property that lowers friction also makes PTFE surfaces highly resistant to sticking. This "non-stick" quality is invaluable for containers, tubing, and devices that handle viscous or sticky materials.

This property ensures that materials flow smoothly and that the components can be cleaned easily and effectively.

Understanding the Trade-offs

While PTFE is the benchmark for low friction, it is not a universal solution. A technical advisor must clarify its limitations to ensure proper material selection.

Impact of Operating Conditions

The effective CoF of PTFE is not a single constant. It can be influenced by factors such as the applied load, sliding speed, and temperature.

Engineers must consider the entire system and operating environment, as extreme conditions can alter performance.

Mechanical Strength and Durability

Standard PTFE is a relatively soft material. While its friction is unparalleled, it has lower compressive strength and wear resistance compared to harder plastics like Nylon or Acetal.

For high-load applications, engineers often use "filled" grades of PTFE, which incorporate materials like glass fiber or carbon to enhance mechanical properties, though this can slightly increase the CoF.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary engineering goal.

- If your primary focus is achieving the absolute lowest friction: PTFE is the undisputed benchmark and should be your default starting point for evaluation.

- If your primary focus is durability in a high-load mechanical system: Consider filled PTFE grades or alternative low-friction polymers like UHMW-PE, accepting a modest trade-off in friction for superior wear resistance.

- If your primary focus is a non-stick surface for handling or transport: PTFE's inherent resistance to adhesion makes it an ideal choice for medical, food processing, and chemical applications.

Ultimately, understanding why PTFE is the standard empowers you to make more informed decisions for any application demanding smooth, reliable motion.

Summary Table:

| Material | Typical Coefficient of Friction (Dynamic) | Key Characteristic |

|---|---|---|

| PTFE | 0.04 – 0.08 | Benchmark: Lowest friction, self-lubricating |

| UHMW-PE | 0.10 – 0.20 | Good wear resistance |

| Acetal | 0.15 – 0.25 | High strength and stiffness |

| Nylon | 0.20 – 0.30 | High toughness and abrasion resistance |

| Lubricated Steel | ~0.05 | Requires external lubrication |

Leverage the benchmark material for your most demanding applications.

At KINTEK, we specialize in precision-manufactured PTFE components—from seals and liners to custom labware—that deliver the unparalleled low-friction performance detailed in this article. Our expertise ensures your designs benefit from reduced wear, self-lubrication, and anti-stick properties critical for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need prototypes or high-volume production, we provide custom fabrication to meet your exact specifications. Let's discuss how our PTFE solutions can enhance your product's performance and reliability.

Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials