For pharmaceutical processes, temperature stability in PTFE/silicone septas is not a feature but a fundamental requirement. These processes frequently expose samples to extreme heat or cold, from high-temperature drug stability studies to cryogenic storage of biologics. A septum's ability to maintain a perfect, impenetrable seal across this wide temperature range is the only thing preventing sample evaporation, contamination, and the complete invalidation of critical analytical data.

A septum's failure at temperature extremes is not a minor inconvenience; it is a catastrophic failure of data integrity. Its stability is the foundation upon which the reliability of pharmaceutical analysis and the assurance of drug safety are built.

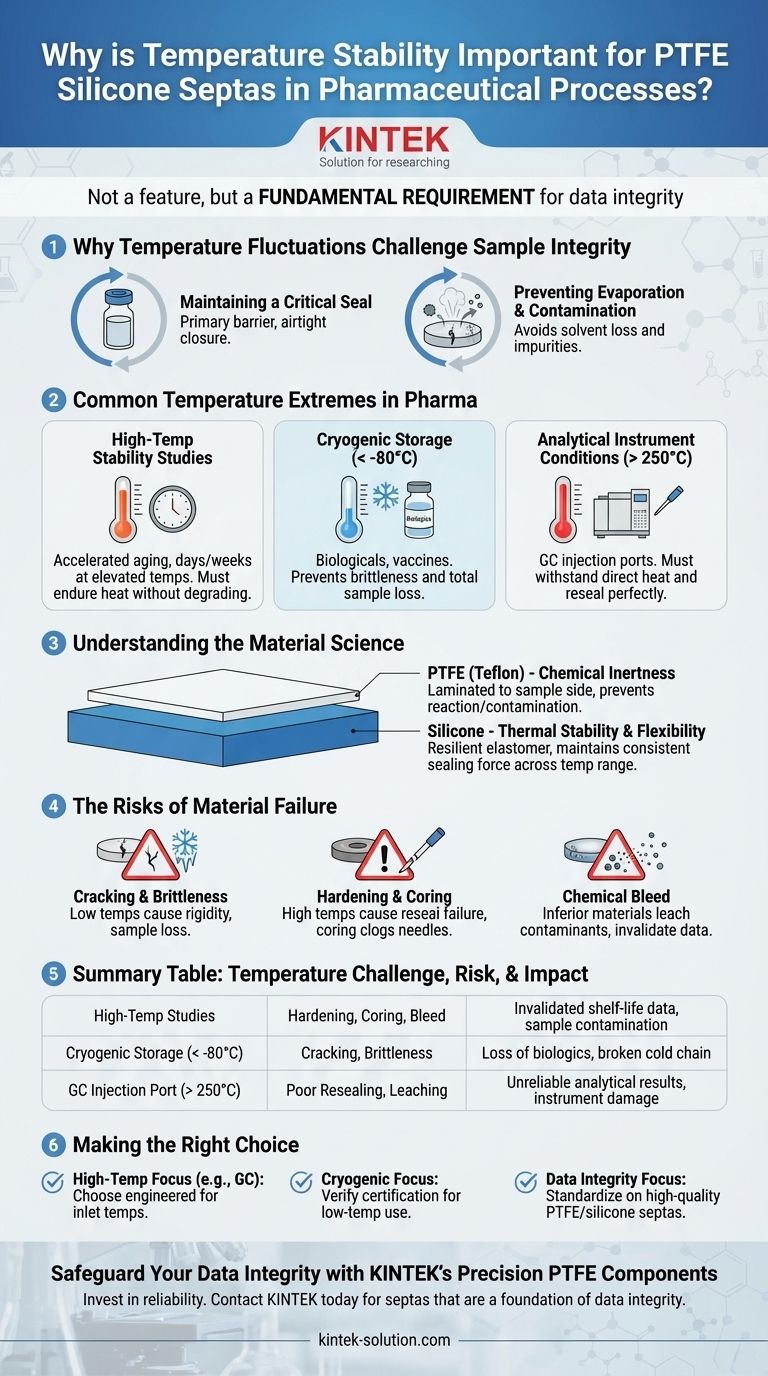

Why Temperature Fluctuations Challenge Sample Integrity

A septum acts as the primary barrier between your sample and the outside environment. Its only job is to maintain a perfect seal, both before and after being punctured by an analytical needle.

Maintaining a Critical Seal

The septum is the gatekeeper of the sample vial. Its primary function is to create an airtight closure that prevents any exchange of material between the inside of the vial and the atmosphere.

Preventing Evaporation and Contamination

If a septum hardens, cracks, or softens due to temperature, the seal is compromised. This can lead to solvent evaporation, which artificially concentrates the sample, or allow contaminants to enter, rendering the results meaningless.

Common Temperature Extremes in Pharma

Pharmaceutical workflows are defined by temperature challenges. PTFE/silicone septas are engineered specifically to perform under these demanding conditions.

High-Temperature Stability Studies

To predict a drug's shelf life, researchers perform accelerated aging studies, exposing the drug product to elevated temperatures. The septum must endure this heat for days or weeks without degrading, leaking, or releasing chemical leachables into the sample.

Cryogenic Storage

Biological samples, vaccines, and certain drug molecules are often stored and transported at cryogenic temperatures (typically below -80°C). At these temperatures, inferior materials can become brittle and crack, causing a total loss of the sample and breaking the cold chain.

Analytical Instrument Conditions

Techniques like Gas Chromatography (GC) use a heated injection port, often exceeding 250°C. The septum must withstand this direct, high heat and reseal perfectly after every injection to ensure reproducible results for the entire analytical sequence.

Understanding the Material Science

The performance of these septas comes from their composite structure, where each material plays a distinct role.

The Role of Silicone

Silicone is a highly resilient elastomer known for its exceptional flexibility across a vast temperature range. It is the workhorse of the septum, providing the consistent sealing force that keeps the vial airtight, whether frozen or heated.

The Role of PTFE (Teflon)

A thin layer of PTFE is laminated to the side of the septum that faces the sample. While silicone provides thermal stability, the PTFE provides chemical inertness, ensuring that no part of the septum reacts with or contaminates the sample.

The Risks of Material Failure

Choosing the wrong septum or a low-quality alternative introduces unacceptable risks into a regulated environment. A failed septum invalidates the data, wastes expensive materials, and can delay development timelines.

Cracking and Brittleness

At low temperatures, a poor-quality septum can become rigid and crack, especially during handling or transport. This results in immediate sample loss and contamination risk.

Hardening and Coring

At high temperatures, a septum can harden, losing its ability to reseal after a needle puncture. This leads to sample evaporation. It can also cause "coring," where fragments of the septum break off and fall into the sample, clogging needles and contaminating the analysis.

Chemical Bleed

Inferior materials may break down under thermal stress and "bleed" volatile or semi-volatile compounds into the sample. These contaminants, known as leachables, can interfere with the analysis and lead to incorrect conclusions about the drug's purity or stability.

Making the Right Choice for Your Process

The septum is a small, inexpensive component, but its impact on data quality is enormous. Selecting the correct one is a critical decision.

- If your primary focus is high-temperature analysis (like GC): Choose a septum specifically engineered and rated for the temperatures of your instrument's inlet to prevent coring and ensure resealability.

- If your primary focus is cryogenic storage of biologics: Verify that the septum is certified for low-temperature use to guarantee its flexibility and prevent the seal from failing due to brittleness.

- If your primary focus is ensuring data integrity across all workflows: Standardize on high-quality PTFE/silicone septas from a reputable supplier to remove a significant and avoidable variable from your analytical results.

Ultimately, investing in a septum with proven temperature stability is a direct investment in the accuracy and reliability of your pharmaceutical data.

Summary Table:

| Temperature Challenge | Risk of Septum Failure | Impact on Pharma Process |

|---|---|---|

| High-Temp Stability Studies | Hardening, Coring, Chemical Bleed | Invalidated shelf-life data, sample contamination |

| Cryogenic Storage (< -80°C) | Cracking, Brittleness | Loss of biologics, broken cold chain |

| GC Injection Port (> 250°C) | Poor Resealing, Leaching | Unreliable analytical results, instrument damage |

Safeguard your pharmaceutical samples and data integrity with KINTEK's precision PTFE components.

Your processes demand materials that perform reliably under extreme thermal stress. KINTEK specializes in manufacturing high-quality PTFE/silicone septas and other critical labware designed for the stringent requirements of the semiconductor, medical, and laboratory industries. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get a perfect seal for every application—from cryogenic storage to high-temperature analysis.

Invest in reliability. Contact KINTEK today to discuss your specific needs and ensure your septas are a foundation of data integrity, not a point of failure.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key applications of the PTFE bottle? Ensure Chemical Safety and Sample Purity

- Why are PTFE lined vials considered durable? Superior Chemical & Thermal Resistance for Reliable Performance

- What are some specific applications of PTFE shovels in the laboratory? Ensure Sample Purity and Safety

- Which sensitive techniques are compatible with PTFE lined vials? Ensure Accurate Trace-Level Analysis

- What are the key components of the Low-Bleed PTFE/Silicone headspace septa and their functions? Ensure Sample Integrity in GC Analysis

- What are the benefits of using high-performance materials in chemical laboratories? Ensure Purity and Reliability

- How does the hydrophobicity of PTFE filters benefit their use? Ensure Uninterrupted Gas Flow and Solvent Filtration

- Why are PTFE filters advantageous for gravimetric analysis? Achieve Unmatched Accuracy and Precision