In the modern laboratory, the humble shovel is a critical tool, and the material it's made from can significantly impact experimental outcomes. PTFE (Polytetrafluoroethylene) shovels are specifically used for three primary applications: the precise handling of chemical samples, the safe transfer of aggressive or viscous liquids, and the non-abrasive cleaning of sensitive laboratory equipment. Their utility stems directly from the unique properties of the PTFE material itself.

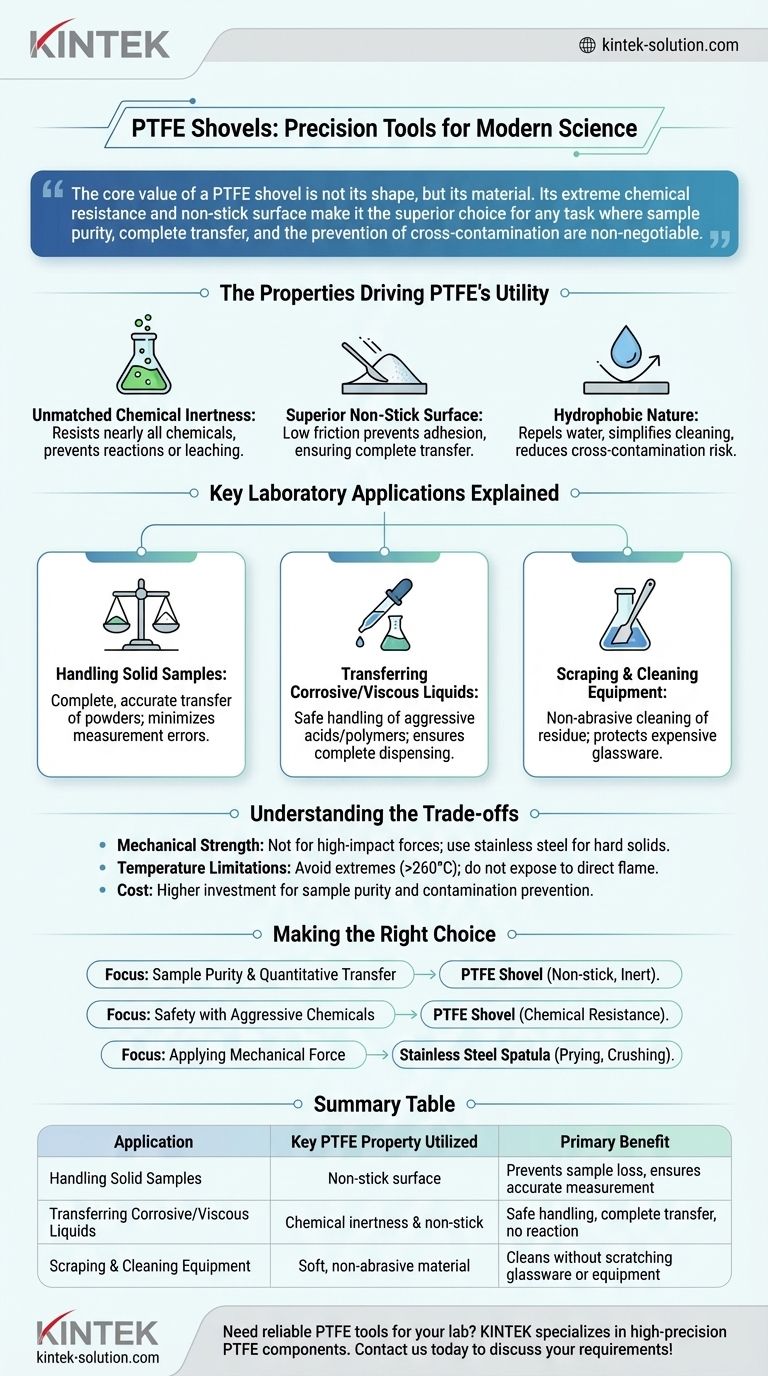

The core value of a PTFE shovel is not its shape, but its material. Its extreme chemical resistance and non-stick surface make it the superior choice for any task where sample purity, complete transfer, and the prevention of cross-contamination are non-negotiable.

The Properties Driving PTFE's Utility

To understand the applications, you must first understand the material. The choice of a PTFE shovel is a choice to leverage a specific set of powerful physical and chemical properties.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to nearly all chemicals, including aggressive acids, bases, and organic solvents. This inertness ensures the shovel will not react with, degrade, or leach impurities into the sample it is touching.

Superior Non-Stick Surface

The famous non-stick quality of PTFE is critical in a laboratory setting. This property, known as a low coefficient of friction, prevents powders, crystals, and viscous liquids from adhering to the shovel's surface.

Hydrophobic Nature

PTFE actively repels water and water-based solutions. This makes it exceptionally easy to clean and dry, drastically reducing the risk of cross-contamination between different samples.

Key Laboratory Applications Explained

These fundamental properties translate directly into specific, high-value uses within a controlled laboratory environment.

Handling and Manipulating Solid Samples

When working with fine powders or crystalline solids, ensuring a complete and accurate transfer is paramount. A PTFE shovel's non-stick surface guarantees that the entire measured sample moves from the container to the reaction vessel without loss.

This minimizes measurement errors and preserves the integrity of quantitative experiments.

Transferring Corrosive or Viscous Liquids

Handling substances like concentrated sulfuric acid or thick polymer solutions presents a dual challenge. The tool must withstand chemical attack while also releasing the thick liquid completely.

PTFE solves both problems. Its chemical resistance prevents the shovel from being damaged, and its non-stick surface ensures that viscous materials slide off easily, enabling accurate dispensing.

Scraping and Cleaning Equipment

Residue left in beakers, flasks, or reaction vessels can be difficult to remove. A PTFE shovel serves as an ideal scraper.

It is chemically inert to any cleaning solvents used, and its material is softer than glass. This allows a researcher to mechanically remove stubborn residues without scratching or damaging expensive glassware.

Understanding the Trade-offs

While highly effective, PTFE shovels are not the universal solution for every task. Understanding their limitations is key to using them properly.

Mechanical Strength

PTFE is a relatively soft material. It is not designed for high-impact or high-force applications. For breaking up hard, caked solids or prying materials apart, a stainless steel spatula is the more appropriate tool.

Temperature Limitations

While PTFE has a high operating temperature, it can degrade and release harmful fumes if heated to extremes (above 260°C or 500°F). It should never be exposed to a direct flame or left on a high-temperature hotplate.

Cost

Compared to simple stainless steel or plastic alternatives, PTFE tools are generally more expensive. The cost is an investment in sample purity and the prevention of contamination.

Making the Right Choice for Your Goal

Selecting the correct tool requires matching its properties to your experimental needs.

- If your primary focus is sample purity and quantitative transfer: The non-stick, inert surface of a PTFE shovel is the ideal choice to prevent sample loss and contamination.

- If your primary focus is safety when handling aggressive chemicals: The unparalleled chemical resistance of PTFE makes it a non-negotiable tool for use with strong acids, bases, or solvents.

- If your primary focus is applying mechanical force: A stainless steel spatula is the correct choice for tasks requiring prying, crushing, or breaking up hardened materials.

Ultimately, choosing a PTFE shovel is a deliberate decision to prioritize the integrity of your sample and the safety of your process.

Summary Table:

| Application | Key PTFE Property Utilized | Primary Benefit |

|---|---|---|

| Handling Solid Samples | Non-stick surface | Prevents sample loss, ensures accurate measurement |

| Transferring Corrosive/Viscous Liquids | Chemical inertness & non-stick | Safe handling, complete transfer, no reaction |

| Scraping & Cleaning Equipment | Soft, non-abrasive material | Cleans without scratching glassware or equipment |

Need reliable PTFE tools for your lab?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including shovels, seals, liners, and labware. Our products are designed for semiconductor, medical, laboratory, and industrial applications where chemical resistance and sample purity are critical. Whether you need custom prototypes or high-volume orders, we ensure superior performance and durability.

Contact us today to discuss your specific requirements and enhance your lab's efficiency and safety with KINTEK PTFE solutions!

Visual Guide

Related Products

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why are PTFE shovels considered cost-effective? Maximize ROI with Superior Durability

- What is PTFE and what are its common uses? A Guide to the High-Performance Polymer

- Which industries commonly use PTFE materials? A Guide to High-Performance Polymer Applications

- What is PTFE and what are its basic properties? The Ultimate Guide to the High-Performance Polymer

- Why is PTFE considered ideal for use in the food and beverage industry? Ensure Safety & Efficiency