At its core, a Low-Bleed PTFE/Silicone headspace septum is a dual-layer system designed for high-purity analytical applications. It consists of a chemically inert Polytetrafluoroethylene (PTFE) layer that faces the sample and a thicker, high-purity silicone layer that provides a reliable mechanical seal against the vial. The "Low-Bleed" designation signifies that the materials are specifically processed to minimize the release of volatile impurities that could interfere with sensitive analysis.

The fundamental purpose of the PTFE/Silicone design is to separate chemical resistance from mechanical sealing. The PTFE provides an inert barrier to protect the sample, while the clean silicone backing ensures an airtight seal and resealability, working together to preserve sample integrity.

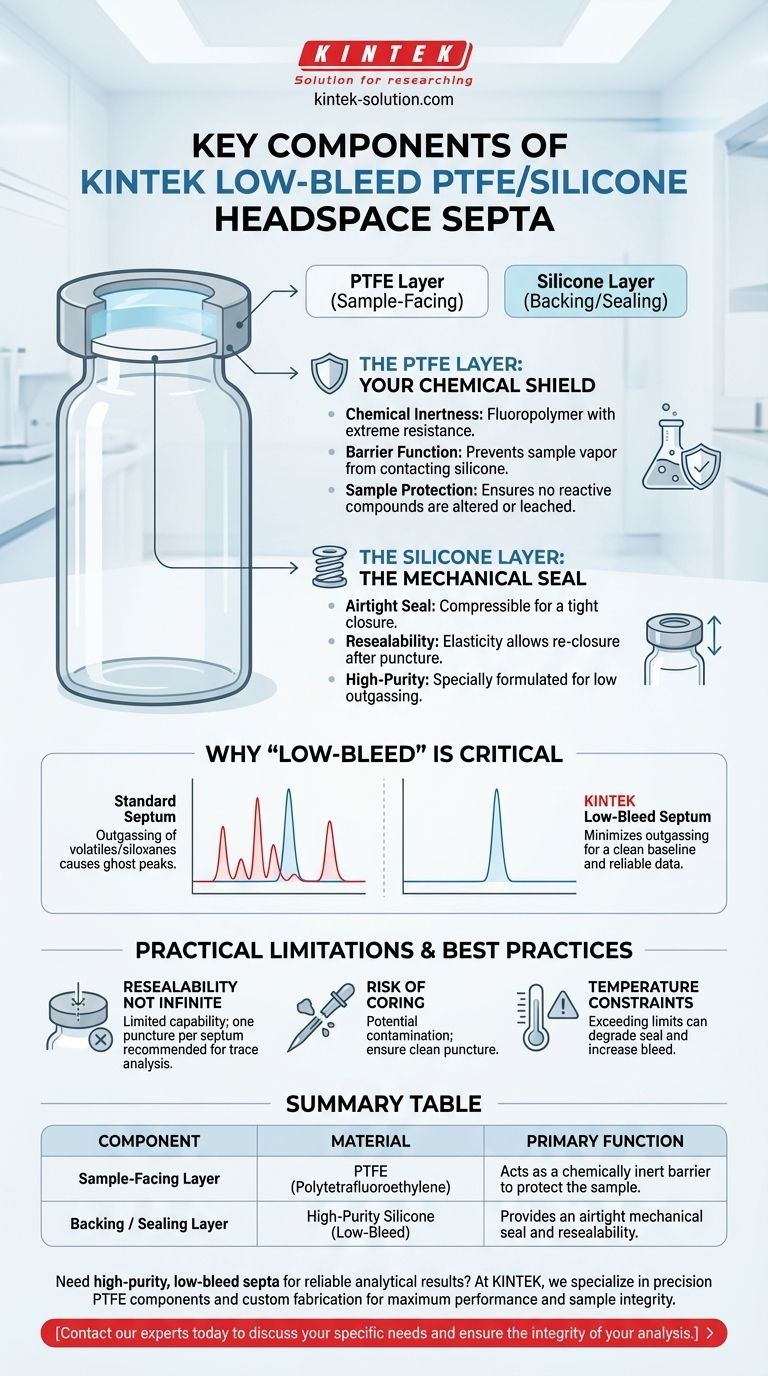

The Anatomy of a High-Performance Septum

To understand why this specific construction is critical, we must break down the distinct role each material plays in the context of headspace gas chromatography (GC), where even minute contamination can compromise results.

The PTFE Layer: Your Chemical Shield

The side of the septum that faces the vial's contents is a thin layer of PTFE, a fluoropolymer known for its extreme chemical inertness.

This layer's sole function is to act as a barrier. It prevents the sample vapor from ever coming into contact with the silicone, ensuring that no reactive compounds in your sample are altered and nothing from the silicone can leach into your vial.

The Silicone Layer: The Mechanical Seal

The bulk of the septum is made from a high-purity, specially formulated silicone. This material is chosen for its physical properties, not its chemical resistance.

Silicone is soft and elastic, which allows it to compress tightly against the vial's rim when crimped, creating an airtight seal. This elasticity also allows the septum to close back around the puncture hole after the autosampler needle is withdrawn, providing a degree of resealability.

Why "Low-Bleed" is a Critical Distinction

The term "bleed" refers to the outgassing of volatile compounds from the septum material itself, typically siloxanes from the silicone.

When heated in a headspace oven, standard silicone can release these compounds, which then enter the GC system along with your sample. This creates unwanted "ghost peaks" in your chromatogram, which can obscure the peaks of interest, especially in trace-level analysis.

A Low-Bleed septum uses silicone that has been specially manufactured and conditioned to minimize this outgassing, ensuring a clean baseline and more reliable data.

Understanding the Practical Limitations

While this design is highly effective, it is essential to be aware of its operational trade-offs to prevent analytical errors.

Resealability is Not Infinite

The reference to resealability means the septum can maintain a seal after being punctured, but this capability is limited. Each puncture creates a permanent hole that is a potential leak path.

For analyses involving highly volatile compounds or when maximum precision is required, it is best practice to puncture each septum only once.

Risk of Coring

Coring occurs when the needle punches out a small disc of the septum material instead of piercing it cleanly. This dislodged piece can potentially clog the syringe needle or fall into the vial, contaminating the sample.

Temperature Constraints

Both PTFE and silicone have upper operating temperature limits. Exceeding the recommended temperature for your specific septum can cause it to degrade, compromising the seal and dramatically increasing the risk of chemical bleed.

Making the Right Choice for Your Goal

Selecting the correct components is the first step toward reliable data. Use your analytical objective to guide your thinking about the septum's function.

- If your primary focus is trace-level analysis: The "Low-Bleed" quality is non-negotiable to prevent ghost peaks from interfering with your results.

- If your primary focus is working with aggressive solvents: The integrity of the PTFE layer is your most critical component, as it provides the essential chemical barrier.

- If your primary focus is method validation: A single-puncture protocol is crucial to eliminate septum leaks as a potential source of variability in your results.

By understanding this two-part design, you can better protect the integrity of every sample and ensure the highest confidence in your analytical outcomes.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Sample-Facing Layer | PTFE (Polytetrafluoroethylene) | Acts as a chemically inert barrier to protect the sample. |

| Backing / Sealing Layer | High-Purity Silicone (Low-Bleed) | Provides an airtight mechanical seal and resealability. |

Need high-purity, low-bleed septa for reliable analytical results?

At KINTEK, we specialize in manufacturing precision PTFE components, including septa, seals, and custom labware for the semiconductor, medical, and laboratory industries. Our expertise ensures your components are designed for maximum performance, minimizing contamination and protecting sample integrity in even the most sensitive applications like headspace GC.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact our experts today to discuss your specific needs and ensure the integrity of your analysis.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials