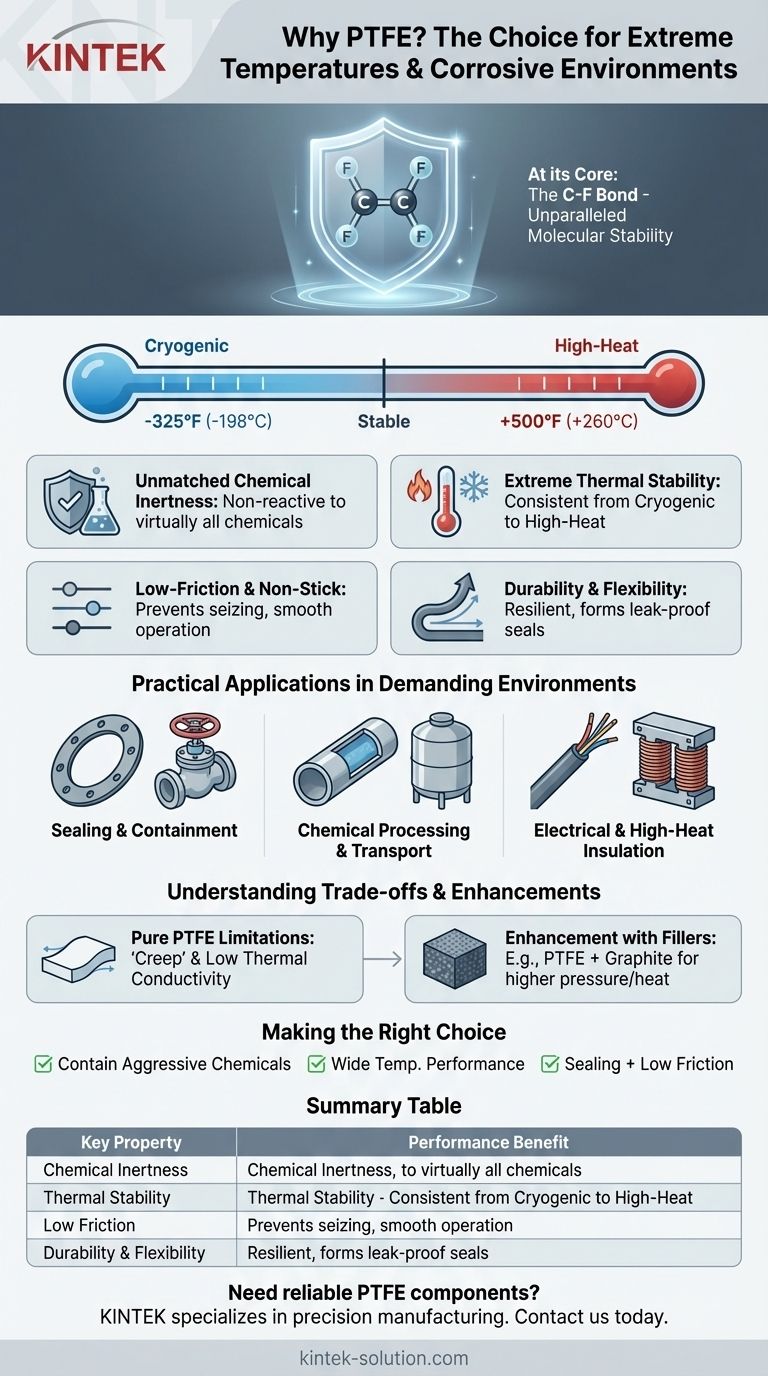

At its core, Polytetrafluoroethylene (PTFE) is chosen for extreme applications because of its unique molecular structure, which provides an unparalleled combination of thermal stability and chemical inertness. It reliably maintains its physical properties across a vast temperature range, from -325°F to +500°F (-198°C to +260°C), while remaining almost completely non-reactive to virtually all industrial chemicals, acids, and bases.

The decision to use PTFE stems from a single principle: its carbon-fluorine bond is one of the strongest in organic chemistry. This molecular stability is the source of its legendary resistance to heat, chemicals, and degradation, making it a default choice for environments where nearly all other polymers would fail.

The Foundation: Unpacking PTFE's Core Properties

To understand why PTFE is so dominant in harsh environments, we must look at its fundamental characteristics. These properties are not independent; they work together to create a uniquely resilient material.

Unmatched Chemical Inertness

The defining feature of PTFE is its non-reactivity. It does not react with, absorb, or degrade when exposed to the most aggressive chemicals.

This makes it invaluable for applications where material purity and integrity are non-negotiable, such as in laboratory equipment, pharmaceutical manufacturing, and chemical transport systems.

Extreme Thermal Stability

PTFE operates reliably across an exceptionally wide temperature spectrum. It remains flexible and pliable at cryogenic temperatures and does not degrade in high-heat processes like ovens or combustion.

Unlike most elastomers that become brittle or melt, PTFE's performance remains consistent, ensuring operational reliability in thermally volatile applications.

Low-Friction and Non-Stick Surface

While not its primary feature for harsh environments, PTFE's extremely low coefficient of friction is a significant secondary benefit.

This property, combined with its durability, makes it ideal for components like bearings, gaskets, and valve seats that must operate smoothly without seizing or degrading from chemical exposure.

Durability and Flexibility

Compared to other inert materials like glass, PTFE offers superior physical resilience. It does not easily break under load and can be flexed to fit custom apparatus layouts.

Its relative softness allows it to form excellent, leak-proof seals, a critical function for containing hazardous or high-purity substances.

Practical Applications in Demanding Environments

The theoretical properties of PTFE translate directly into critical real-world applications where failure is not an option.

Sealing and Containment

Because it forms excellent seals and resists nearly all chemicals, PTFE is a primary material for gaskets, O-rings, and valve components. It prevents leaks in systems handling everything from corrosive acids to high-pressure fluids.

Chemical Processing and Transport

PTFE is used to line pipes, tanks, and reactors. Tubing and stirrers made from PTFE can be constantly immersed in chemicals without being modified, ensuring the purity of the process and the longevity of the equipment.

Electrical and High-Heat Insulation

The combination of high heat resistance and excellent dielectric properties makes PTFE a superior choice for wire insulation and components in transformers, especially in aerospace and industrial settings where high temperatures are common.

Understanding the Trade-offs and Enhancements

No material is perfect, and trusting PTFE requires understanding its limitations and how they are addressed.

Limitations of Pure PTFE

While chemically robust, pure PTFE can be susceptible to "creep" or cold flow, meaning it can deform over time when under a constant mechanical load. Its thermal conductivity is also relatively low, which can be a drawback in applications that need to dissipate heat.

The Role of Fillers

To overcome these limitations, PTFE is often blended with other materials. For example, PTFE graphite packing combines PTFE's chemical resistance with graphite's superior thermal conductivity and strength.

This enhancement allows the composite material to handle higher pressures and temperatures, making it suitable for demanding sealing applications in power generation and chemical processing.

Making the Right Choice for Your Application

Selecting PTFE is a decision based on ensuring reliability where other materials would present a significant risk.

- If your primary focus is containing aggressive chemicals: PTFE's near-universal inertness makes it the safest and most reliable choice to prevent corrosion and contamination.

- If your primary focus is performance across a wide temperature spectrum: Its stability from cryogenic lows to sustained high heat ensures predictable mechanical performance.

- If you need a combination of sealing, low friction, and chemical resistance: PTFE's unique blend of properties offers a comprehensive solution for dynamic components like valves and bearings in harsh settings.

Ultimately, PTFE serves as a foundational engineering material, providing a direct and effective solution for the most demanding operational challenges.

Summary Table:

| Key Property | Performance Benefit |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and bases |

| Thermal Stability | Maintains properties from -325°F to +500°F (-198°C to +260°C) |

| Low Friction | Non-stick surface prevents seizing in valves and bearings |

| Durability & Flexibility | Forms leak-proof seals while withstanding physical stress |

Need reliable PTFE components for your most demanding applications?

KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, and more) for semiconductor, medical, laboratory, and industrial applications. Our custom fabrication services—from prototypes to high-volume orders—ensure you get components that withstand extreme temperatures and corrosive environments while maintaining operational integrity.

Contact us today to discuss how our PTFE solutions can enhance your equipment's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance